Hydraulic Dynos: Applications in Heavy Industry Jobs

Hydraulic dynos prevent catastrophic field failures—but most heavy industry operators still skip this critical step. Learn why.

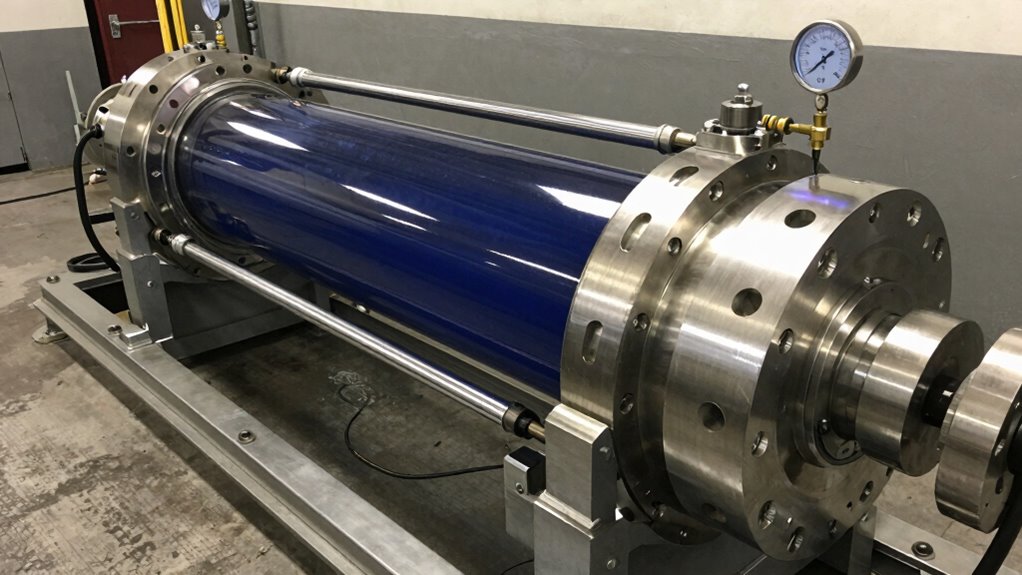

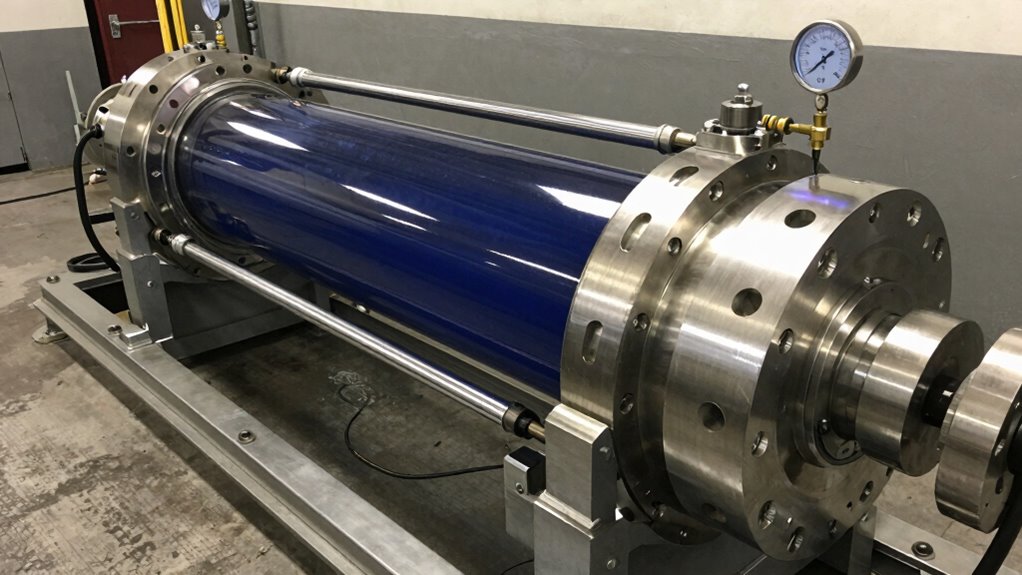

A modern dynamometer system comprises five vital components that work together to accurately measure torque, speed, and power output of a unit under test.

The mechanical unit forms the core, absorbing the power output, while sensors capture accurate measurements of torque, speed, and power.

The control system interprets sensor data, applying calibration factors and calculating performance metrics.

The data acquisition system collects and processes data, providing real-time feedback, and the user interface enables engineers to interact with the system.

Understanding these components enables engineers to tap the full potential of dynamometer testing, revealing critical insights into machine performance and optimisation.

A modern dynamometer system comprises five key components that work in harmony to measure torque, speed, and power. These components consist of the mechanical unit, sensors, control system, data acquisition system, and user interface.

The mechanical unit forms the core of the dynamometer, responsible for absorbing the power output of the unit under test (UUT) and converting it into a measurable force or torque, thus enabling accurate measurements of the UUT's performance.

The sensors, control system, and data acquisition system collaborate to capture and process the measurements, providing an in-depth understanding of the UUT's behaviour.

The control system interprets the sensor data, applying calibration factors and calculating performance metrics such as power and efficiency.

The data acquisition system and user interface enable users to configure tests, monitor real-time data, and analyse results, providing valuable insights into the UUT's operation.

This integration of components ensures a modern dynamometer system provides precise and reliable measurements of torque, speed, and power.

Within modern dynamometer systems, sensors and transducers capture accurate and reliable measurements of torque, speed, and power.

These components convert mechanical parameters into electrical signals, which are then processed and analysed to provide meaningful insights.

Strain gauge-based dynamometers, for instance, are commonly used in Friction stir welding and resistance welding to measure forces, displacement, and pressure acting on the welding tool and base material.

Piezoresistive and piezoelectric sensors measure the pressure of the welding arc, while electronic transducers provide accurate data on well loads and rod displacements.

Position transducers accurately measure polished rod instantaneous acceleration, enabling precise calculations of power output and torque.

Load cells, such as horseshoe-type load cells, measure loads with an accuracy of 0.5% or better of its rated load.

Modern dynamometers provide an in-depth knowledge of the forces exerted, allowing for precise control and optimisation of diverse industrial processes.

We can scrutinize the mechanical unit and control system of a modern dynamometer, which play a crucial role in governing the load applied to the engine or motor under test.

The mechanical unit typically consists of a rotor and stator, with the rotor connected to the engine or motor under test and the stator connected to the stationary frame. This design enables the dynamometer to accurately measure power output, torque, and speed.

The control system is similarly critical, governing the load applied to the engine or motor under test and ensuring accurate and repeatable measurements.

Modern dynamometers employ advanced control systems, such as servo-controlled hydraulic or electric motors, to provide precise load control and flexibility in testing protocols. The mechanical unit and control system work together to absorb the power output of the engine or motor under test, converting it into heat or other forms of energy that can be safely dissipated.

The design and construction of these components are critical to the accuracy, reliability, and safety of dynamometer testing, and must be carefully optimised for specific applications and testing requirements.

A modern dynamometer's data acquisition system comprises several key components that play a pivotal role in collecting and processing the vast amounts of data generated during testing.

This system is responsible for real-time data acquisition, capturing accurate and reliable dynamometer measurements of torque and rotational speed. Dynamometers measure these parameters to provide highly accurate and precise measurements, which are vital for testing and analysing the performance of engines, motors, and other machines.

The system consists of sensors, signal conditioning units, and data processing software.

These components work together to measure torque and power, converting raw sensor data into meaningful and actionable information. The system's ability to provide precise measurements and real-time feedback enables engineers and technicians to make informed decisions about design modifications, performance optimisation, and troubleshooting.

Modern dynamometers can generate vast amounts of valuable data using advanced data acquisition technologies, which can be used to improve product design, reduce development time, and boost total system effectiveness.

A dynamometer's cooling and power supply systems play a critical role in guaranteeing the accuracy and reliability of test results, as they directly impact the unit's ability to operate within specified parameters.

Modern dynamometers employ diverse cooling and power supply configurations to achieve this, including water cooling systems that dissipate heat generated during high-power testing, with water flow rates ranging from 10-50 gallons per minute.

Air-cooled dynamometers, reliant on heat sinks, fans, and clever design, dissipate heat, making them suitable for lower-power applications.

Three-phase AC power supplies have voltage and current ratings that match the maximum power output of the unit under test.

DC power supplies, used in smaller dynamometers or those designed for low-power testing, provide stable and stabilised power to verify accurate test results.

These configurations enable dynamometers to handle high currents and voltages while maintaining precise control over power outputs.

Careful selection and integration of these components allow dynamometers to operate within specified parameters, guaranteeing reliable and accurate test results.

Within the domain of dynamometer technology, software and integration are pivotal in unshackling the full potential of these testing devices.

Modern dynamometer software typically features a user-friendly interface, data acquisition and analysis capabilities, and customizable test protocols to meet specific application requirements.

Standardized communication protocols such as EtherNet/IP, Modbus, or CANbus facilitate integration with other systems, including data loggers and controllers.

Advanced software features include real-time data visualization, automated test sequencing, and data exportation in diverse formats, such as CSV or Excel.

Some dynamometer software packages offer simulation capabilities, allowing users to model and analyse complex systems before conducting physical tests.

Integration with machine learning algorithms and artificial intelligence enables predictive maintenance, aberration detection, and performance optimization in dynamometer applications.

Users can release the full potential of their dynamometers and streamline their testing processes through these software and integration capabilities.

The Essential Components of a Modern Dynamometer

Key Components Overview

At Hyper Power, we understand that a modern dynamometer is a complex system comprising several crucial components that work in tandem to measure the mechanical performance of engines, motors, and other mechanical devices. These components can be broadly classified into five categories: sensors and transducers, mechanical unit and control, data acquisition system, cooling and power supply, and software and integration. If you have any questions about our services, including Custom Dyno Solutions, Installation and Setup, Training and Certification, Technical Support and Maintenance, Software Updates and Upgrades, Diagnostics and Performance Analysis, Rental Services, Dynamometer Testing Services, and Accessories and Parts, please do not hesitate to contact us.

Sensors and Transducers

Sensors and transducers are responsible for converting mechanical parameters such as torque, speed, and position into electrical signals. These signals are then processed and analysed to provide accurate measurements. Common sensors and transducers used in dynamometers include strain gauges, piezoelectric sensors, and optical encoders.

Mechanical Unit and Control

The mechanical unit is the heart of the dynamometer, providing the mechanical interface between the device under test and the dynamometer. It consists of a rotor, stator, and bearings that enable the rotation or movement of the device. The control system governs the mechanical unit, ensuring precise control over the test parameters.

Data Acquisition System

The data acquisition system is responsible for collecting and processing the electrical signals from the sensors and transducers. It typically consists of analogue-to-digital converters, signal conditioning circuits, and data storage devices. The system enables real-time data acquisition, ensuring that accurate measurements are obtained.

Cooling and Power Supply

The cooling system is vital for maintaining the dynamometer's operating temperature within a safe range. It prevents overheating, which can lead to inaccurate measurements and damage to the equipment. The power supply unit provides stable and controlled power to the dynamometer's components, ensuring reliable operation.

Software and Integration

The software component of the dynamometer provides a user-friendly interface for operating the system, analysing data, and generating reports. It unites the diverse components of the dynamometer, enabling seamless communication and data exchange.

Conclusion

A modern dynamometer's performance is contingent upon the harmony of its crucial components. The integration of advanced sensors, mechanical units, data acquisition systems, cooling and power supply systems, and software enables accurate and reliable measurements of mechanical performance. At Hyper Power, we are dedicated to providing exceptional Custom Dyno Solutions, Installation and Setup, Training and Certification, Technical Support and Maintenance, Software Updates and Upgrades, Diagnostics and Performance Analysis, Rental Services, Dynamometer Testing Services, and Accessories and Parts. Please contact us if you require any further information about our services.

Hydraulic dynos prevent catastrophic field failures—but most heavy industry operators still skip this critical step. Learn why.

Most diesel dyno operators ignore this—and it costs them thousands in failed runs and wasted data.

Stop wasting money on road testing. One dyno investment eliminates comebacks, builds loyalty, and outpaces competitors. Here’s why your workshop needs it.

Diesel turbo lag isn’t inevitable—modern dyno diagnostics reveal the hidden culprits stealing your power. Find out what your engine is hiding.

Fleet operators are throwing money away. Dynos reveal what road tests miss—and how much you’re losing.

Water testing won’t reveal what dyno testing exposes. Learn why engine builders skip this step at their peril.

Tractor performance tests reveal what manufacturers won’t tell you. See how dynamometer data exposes hidden inefficiencies in your equipment.

Diesel engine testing mistakes cost thousands monthly. Learn what separates thriving operations from regulatory nightmares.

No posts found!