Fleet Fuel Efficiency: Optimising Trucks With Dynos

Fleet operators are throwing money away. Dynos reveal what road tests miss—and how much you’re losing.

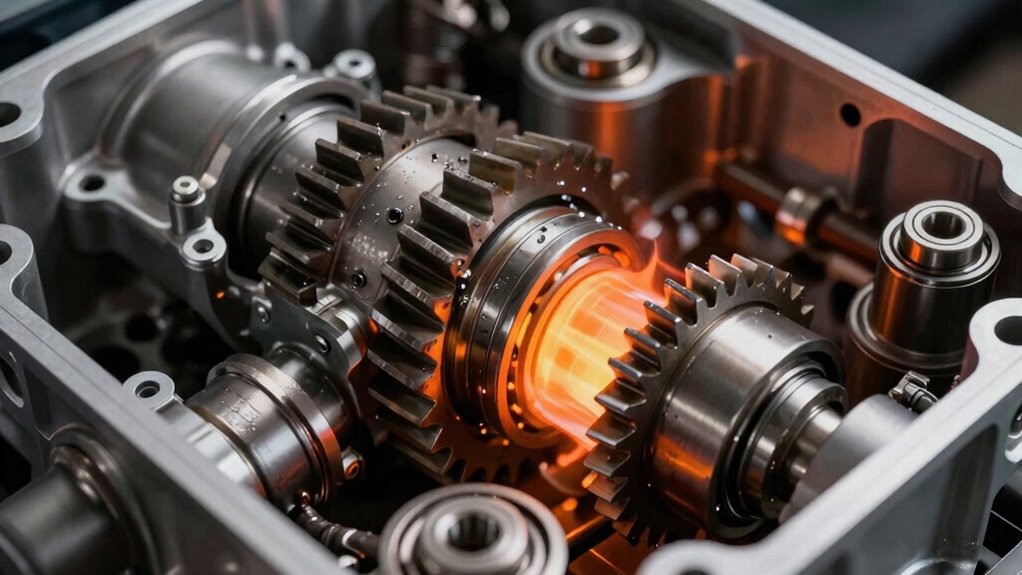

Your engine’s rated horsepower is a lie. The actual power reaching your wheels is substantially less—sometimes 15-20% vanishes before it even matters. Transmissions, differentials, and driveshafts quietly steal energy through mechanical friction, yet most drivers never question this invisible tax on performance. Two identical engines can feel radically different behind the wheel depending on how efficiently these components transfer power. Understanding parasitic drag reveals the real reason your car performs the way it does.

Most vehicle owners never consider what happens to the engine power between the crankshaft and the wheels, yet the route is far from direct.

Drivetrain systems absorb a significant portion of engine output through various mechanical and fluid losses, meaning the horsepower advertised rarely reaches the pavement.

Understanding where power disappears requires examining multiple loss sources. Transmission fluid resistance, differential friction, and bearing drag all consume energy that could otherwise drive the vehicle.

Transmission fluid resistance, differential friction, and bearing drag consume the engine power that could otherwise propel your vehicle forward.

Tire sidewall flexing and rolling resistance further diminish available power at the wheels. Manual transmissions typically incur 2-5% power loss, making them more efficient alternatives to automatic options.

Typical losses range from 10-25% depending on drivetrain configuration and design choices. Comprehensive dynamometer testing can precisely measure these losses across different drivetrain configurations. Rear-wheel drive vehicles lose approximately 15%, while all-wheel drive systems experience 20-25% losses.

Strategic drivetrain upgrades—including lighter driveshafts and improved differentials—enhance power efficiency, ensuring more engine output reaches the wheels where it matters most.

When a vehicle sits on a chassis dynamometer, the equipment measures power at the drive wheels rather than at the engine’s flywheel, capturing only the horsepower actually delivered to the pavement after drivetrain losses have already occurred.

Engine dynos, by contrast, measure raw power output before transmission, differential, and bearing friction consume a portion of that energy, typically 15% for rear-wheel drive vehicles and 20-25% for four-wheel drive systems.

Comprehending the distinction between these two measurements is essential for interpreting dyno results accurately and recognising how much power is genuinely available for real-world acceleration and performance. Our premium dynamometer shop offers the high-quality accessories and upgrades necessary to minimise measurement errors during testing. Selecting knowledgeable dyno operators is crucial for ensuring that your test results reflect true power delivery rather than measurement errors caused by tyre slip or inadequate engine cooling.

Why do two different dynamometers produce vastly different horsepower readings for the same vehicle?

The answer lies in measurement location and what variables each captures. Engine dynos measure crankshaft power directly, stripped of drivetrain components. Chassis dynos measure wheel power after transmission, differential, and bearing losses occur. This fundamental difference creates the gap in engine performance readings.

Key Measurement Differences:

Understanding these distinctions guarantees dyno accuracy when evaluating your vehicle’s true performance capabilities and identifying where power is actually lost. At Hyper Power International, our precision testing services ensure you receive accurate measurements tailored to your specific vehicle requirements. Data acquisition systems collect sensor measurements during acceleration to compute the precise horsepower and torque figures that reveal your actual power loss across the drivetrain.

Dynamometer readings represent a controlled snapshot of vehicle performance, yet they often deviate significantly from what drivers experience on the road or track. Dyno calibration standards vary greatly between regions and equipment manufacturers, creating substantial measurement inconsistencies. A vehicle’s actual power delivery depends on variables that dynos struggle to replicate authentically. While competent tuners can achieve accurate results on various dynamometer brands, the proprietary methods each manufacturer employs for recording horsepower and torque complicate direct comparisons across different equipment. Professional installation and calibration ensures that dyno measurements are as accurate as possible within controlled environments.

| Factor | Dyno Environment | Real-World Conditions | Impact on Power |

|---|---|---|---|

| Tyre Pressure | Controlled | Variable | 5-15% variance |

| Road Load | Simulated | changing | 10-20% difference |

| Temperature | Stable | Fluctuating | 3-8% reduction |

| Traction | Limited | Full engagement | 20%+ variance |

| Ambient Conditions | Regulated | Uncontrolled | 5-10% variance |

Engine torque curves at lower RPMs better drive real-world performance, while chassis dynos cannot fully account for drivetrain complexity. Continuous-load systems provide measurements closest to actual operating conditions, offering professionals reliable data for genuine performance assessment and optimisation.

The transmission represents one of the most significant variables in drivetrain efficiency, with manual and automatic designs operating under fundamentally different mechanical principles that directly impact power delivery at the wheels.

Manual transmissions achieve superior efficiency ratings of 90-95% through direct gear engagement and minimal friction, while automatic transmissions with torque converters typically max out at 80-85% efficiency due to inherent slippage and internal pump losses accounting for 30-40% of total transmission power consumption.

Modern lock-up technology in automatic transmissions attempts to bridge this efficiency gap by eliminating converter slippage during steady-state driving, yet the fundamental hydraulic complexity of automatics continues to result in measurably higher drivetrain losses compared to their manual counterparts. AWD systems experience higher losses due to their complex torque paths and additional drivetrain components compared to manual or automatic FWD configurations.

Transmission type fundamentally shapes how efficiently a vehicle converts engine power to the wheels, making the manual-versus-automatic debate far more complex today than it was decades ago.

Historical manual transmission advantages once delivered 15-20% better fuel economy, but automatic transmission innovations have shifted this environment dramatically since 2016.

Modern automatics now feature up to nine gears compared to six in manuals, enabling superior engine speed matching and minimal parasitic drag. This technological advancement has positioned automatics ahead in manufacturer efficiency ratings.

Key efficiency factors include:

Real-world performance, however, remains condition-dependent, with skilled manual operators maintaining competitive advantages in specific scenarios.

While modern automatic transmissions have narrowed the efficiency gap with their manual counterparts through advanced gearing and lock-up technology, a fundamental mechanical reality still separates them: the torque converter‘s inherent slippage.

The torque converter enables power multiplication during acceleration by allowing the impeller to spin faster than the turbine, creating controlled slippage. However, this same mechanism becomes a liability at cruising speeds without engagement, causing response delay and efficiency variations throughout the driving cycle.

Slippage symptoms manifest as gear engagement issues, shuddering vibration, and transmission overheating from excess heat generation.

Root slippage causes include clutch wear, defective solenoids interfering with fluid flow, and fluid contamination reducing coupling effectiveness.

Comprehending these interactions helps professionals identify parasitic losses and enhance transmission performance strategically.

As automatic transmissions evolved beyond the torque converter’s inherent slip limitations, lock-up clutch technology emerged as a critical efficiency breakthrough. This hydraulic mechanism directly connects the engine to the transmission input shaft, eliminating parasitic losses that plague traditional fluid coupling systems.

Lock-up functionality delivers measurable performance gains:

Modern transmissions enable lock-up engagement across multiple gears, from 6-speed to 10-speed units. This flexibility allows engineers to balance efficiency with drivability, ensuring peak power transfer across varied driving conditions while maintaining transmission longevity. Proactive system monitoring through dynamometer testing can validate lock-up performance characteristics and identify optimisation opportunities for specific vehicle applications.

The driveshaft represents a critical component in any vehicle’s powertrain, responsible for transferring engine torque to the wheels while managing rotational forces under varying load conditions. Material selection directly impacts parasitic power loss and overall drivetrain efficiency.

Steel driveshafts offer proven durability and cost-effectiveness, making them ideal for heavy-duty applications. However, their weight increases rotating mass, requiring additional engine power per rotation.

Steel driveshafts deliver proven durability and cost-effectiveness for heavy-duty applications, though their weight demands additional engine power per rotation.

Aluminium alternatives reduce weight by 10-20 pounds, providing quicker acceleration and smoother shifting through decreased inertia. Carbon fibre provides maximum weight reduction for performance builds, though at premium cost.

Racing applications benefit most from lightweight options, while daily-use vehicles typically favour steel’s superior repairability and affordability, balancing performance gains against practical maintenance considerations. Dynamometer accessories enable precise measurement of power loss differences across various driveshaft materials, facilitating informed selection for specific performance requirements.

Differentials serve as the critical junction where engine torque splits between the driving wheels, yet their design fundamentally shapes how a vehicle performs under varying traction conditions.

Open Differential Benefits

Open differentials dominate passenger vehicles due to their straightforward mechanics and efficiency advantages:

Limited Slip Advantages

Limited-slip differentials introduce mechanical resistance through clutch packs, increasing complexity but providing superior traction control.

This design biases torque toward the gripped wheel, enabling immediate acceleration on loose surfaces where open differentials spin freely.

Performance gains emerge noticeably during spirited driving above 3,000 RPM, though motorway efficiency suffers from added parasitic drag.

Selecting between these systems requires assessing traction demands against efficiency priorities for your specific driving application, and staying current with software updates ensures your dynamometer provides accurate performance measurements for both differential types.

While all-wheel drive systems deliver undeniable traction advantages, they accomplish this benefit at a significant efficiency cost that becomes unavoidable once the additional mechanical complexity enters the drivetrain.

AWD typically loses 20-25% of crankshaft power compared to RWD’s 15-20%, representing a substantial efficiency trade-off for the traction benefits gained.

AWD systems sacrifice 20-25% power efficiency versus RWD’s 15-20% loss—a substantial trade-off for superior traction.

The culprit lies in component friction. Transfer cases, extra driveshafts, and multiple differentials create cumulative power absorption throughout the system.

Hypoid gearsets alone generate 6-10% losses, amplified across AWD designs. Gear meshing, bearings, seal drag, and windage compound these inefficiencies. A 500 HP engine may deliver only 375-400 HP at the wheels—a 20-25% penalty.

This complexity demands measurable sacrifices. Real-time performance evaluations reveal exactly where power losses occur in AWD systems, enabling data-driven optimisation decisions.

However, professionals recognise that traction superiority justifies the efficiency loss in demanding conditions where additional grip proves essential.

Comprehending where power disappears in a drivetrain is only half the battle—the real challenge lies in recovering it through measurable engineering interventions.

Strategic drivetrain optimisation techniques directly address the mechanical inefficiencies that rob vehicles of performance and efficiency.

Proven Power Recovery Methods:

These interventions, when properly implemented and measured using advanced dynamometer systems, deliver quantifiable gains in power delivery and vehicle responsiveness. Validating these performance improvements requires custom dyno solutions specifically configured to capture the precise efficiency metrics of your unique drivetrain architecture.

The path that engine power travels to reach the wheels determines how much energy dissipates as heat and friction before providing real performance to the road.

FWD systems deliver the most efficient power transfer, losing approximately 10-15% through their direct torque path and helical final drive gears.

RWD configurations experience roughly 15% losses, with driveshaft and differential components adding parasitic drag.

AWD setups suffer the highest drivetrain efficiency penalties at 20-25%, as multiple differentials, transfer cases, and additional driveshafts force power through numerous friction points.

A 500 HP engine yields approximately 425 WHP in RWD versus 400 WHP or less in AWD.

Comprehending these drivetrain variations enables professionals to enhance vehicle performance and select appropriate testing protocols on dynamometer systems.

Fleet operators are throwing money away. Dynos reveal what road tests miss—and how much you’re losing.

Water testing won’t reveal what dyno testing exposes. Learn why engine builders skip this step at their peril.

Tractor performance tests reveal what manufacturers won’t tell you. See how dynamometer data exposes hidden inefficiencies in your equipment.

Diesel engine testing mistakes cost thousands monthly. Learn what separates thriving operations from regulatory nightmares.

Build a diesel dyno empire while most workshops fail—here’s what separates winners from the rest.

Most dyno operators ignore this one calibration step—and it’s costing them thousands in poor data.

Force and torque aren’t opposites—they work together in ways most people misunderstand. Learn how this relationship transforms machine performance.

Your engine’s power never reaches your wheels—here’s why and what it costs you.