Fleet Fuel Efficiency: Optimising Trucks With Dynos

Fleet operators are throwing money away. Dynos reveal what road tests miss—and how much you’re losing.

Meta Description:

Your tractor might be underperforming and you’d never know it. Standard inspections miss what dynamometer testing reveals: hidden mechanical inefficiencies draining fuel and power. Operators who rely on manufacturer specs alone are flying blind, while those using precision diagnostics catch problems others ignore. Learn which testing methods separate equipment that merely runs from machinery that performs.

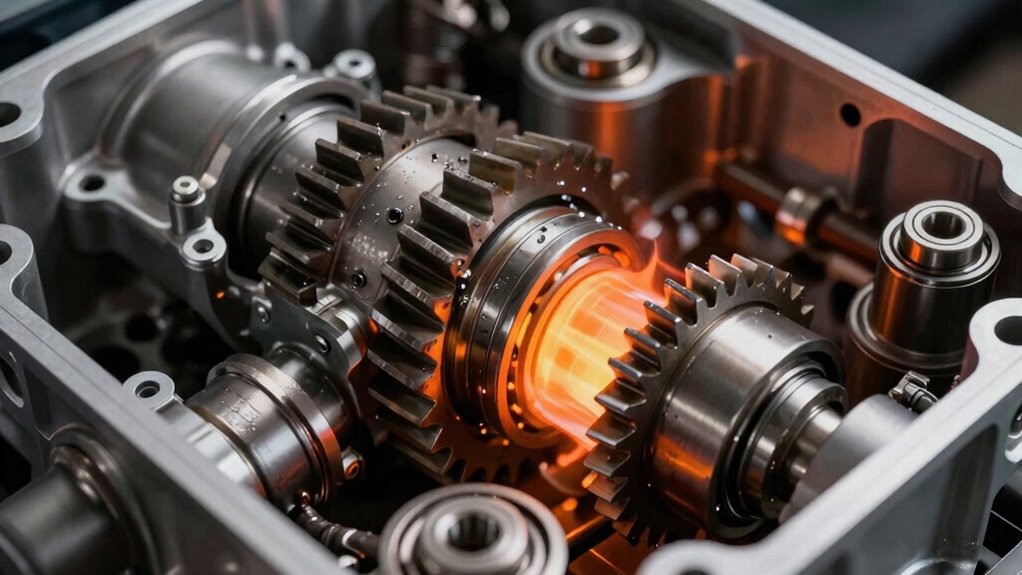

The backbone of modern agricultural performance lies in understanding exactly what an engine delivers. A dynamometer is a precision instrument that measures force, torque, and rotational speed to calculate actual power output in horsepower or kilowatts. Unlike manufacturer specifications alone, dynamometer testing provides real-world performance data.

Agricultural operations demand reliability and efficiency. Tractors face variable terrain, seasonal demands, and heavy loads requiring verified engine performance. Testing benefits include identifying mechanical issues before field implementation, comparing actual output against manufacturer claims, and optimising fuel efficiency. Engine dynamometers can test engines removed from vehicles to confirm performance before reinstallation, while chassis dynamometers test the entire drivetrain simultaneously. Our detailed performance reports deliver actionable insights that support informed decision-making for equipment optimisation.

Dynamometer types range from absorption units for basic measurements to regenerative systems for complex load simulations. These configurations allow operators to replicate specific working conditions farmers encounter.

Thorough testing guarantees tractors perform dependably under demanding agricultural conditions, protecting investments and maximising productivity throughout harvest seasons.

Because agricultural equipment operates across diverse climates and seasons, standardised testing conditions ascertain that dynamometer results remain consistent and comparable regardless of when or where measurements occur.

Hyper Power maintains strict environmental controls during all agricultural testing. Ambient temperature is held at 24°C, while barometric pressure must exceed 28.5 inches of mercury. These parameters reduce environmental impact on measurement validity and ascertain testing reliability across different geographic locations. Our cutting-edge software solutions continuously monitor and log all environmental variables throughout the testing process.

Data collection occurs at stabilised conditions using calibrated equipment across multiple channels. Temperature, humidity, and pressure readings are logged at maximum pull levels and partial loads—75% and 50% of maximum drawbar force.

Pre-test verification confirms all conditions meet procedural requirements before compulsory assessments begin, ascertaining accurate, repeatable results that clients can trust. Similar to OECD tractor testing standards, these rigorous protocols ensure that independent laboratory verification provides unbiased and standardised measurement outcomes across all agricultural equipment evaluations.

Precision measurement of agricultural tractor performance demands eliminating variables that obscure actual drivetrain capability, and hub dynamometers accomplish this by connecting directly to axle hubs after wheel removal. This approach provides superior torque measurement accuracy compared to rolling road methods, capturing authentic drivetrain diagnostics without tyre slip interference.

Key Technical Advantages:

Hub dynamometers apply calibrated braking force through direct axle connection, allowing electronic control systems to adjust generator output during testing. This labour-intensive setup requires secure mounting and a dedicated facility to ensure measurement consistency across multiple test cycles. Custom software solutions can enhance the testing experience by providing seamless integration with existing facility infrastructure.

Operators simultaneously measure torque and rotational speed, calculating drivetrain efficiency under steady-state conditions. This methodology delivers precise, comparable measurements essential for thorough equipment evaluation.

Rolling road dynamometers excel at reproducing the authentic conditions tractors encounter in agricultural work, where terrain variations, load distributions, and multi-directional forces demand thorough performance evaluation.

By measuring torque delivery through the wheels rather than at the engine, these systems capture the real-world impact of tyre slip, traction characteristics, and drivetrain losses—revealing critical differences between 2WD and 4WD performance that bench testing cannot replicate.

This capability allows operators to assess how tractors respond to varied field demands, from steep inclines to demanding drawbar loads, providing actionable data that informs both equipment selection and optimisation strategies. The RENK RDDS system integrates extensive measurement equipment to manage both common test programmes and custom test runs, enabling operators to modify testing protocols independently based on evolving agricultural requirements. These precision testing services ensure that equipment performance meets the demanding standards required for modern agricultural operations.

When tractors operate in actual agricultural environments, they encounter unpredictable variables—soil resistance, tyre slip, fluctuating load shifts, and terrain changes—that traditional stationary engine testing cannot replicate.

Rolling road roller dynamometers bridge this gap, providing authentic field simulation within controlled laboratory settings.

Modern facilities employ sophisticated roller systems capable of replicating complex agricultural scenarios. These systems measure critical performance metrics while maintaining repeatability impossible to achieve outdoors. The PLC-based data collection systems integrated into advanced dynamometers enable real-time monitoring and precise control of testing parameters across multiple channels simultaneously. Our proactive system monitoring approach ensures that dynamometer performance remains optimal throughout extended testing cycles.

Key simulation capabilities include:

This approach eliminates environmental variables while preserving real-world testing conditions, enabling engineers to develop more efficient, reliable tractors for demanding agricultural applications.

The controlled laboratory environment that enables field condition simulation also serves as an ideal platform for evaluating how different drivetrain configurations perform under identical loading scenarios.

Rolling road dynamometers allow operators to measure performance metrics across 2-wheel drive and 4-wheel drive modes, revealing how each drive mode affects power delivery and efficiency under load.

Professionals seeking to master these comparative testing techniques can pursue certification in dynamometer technology to ensure reliable and accurate results across all drive mode evaluations.

PTO dynamometers measure tractor engine power directly at the Power Take-Off shaft, providing the most accurate assessment of mechanical output available to agricultural operators.

By connecting to the PTO at standardised speeds of 540 or 1000 RPM, these systems apply controlled load through water brake or Prony brake mechanisms while simultaneously recording torque and rotational speed data.

This direct measurement approach, governed by ISO 500 standards, establishes repeatable performance baselines that allow operators to verify rated horsepower, diagnose efficiency losses, and compare results against manufacturer specifications with clinical precision. Real-time performance evaluations enhance the reliability and accuracy of these testing outcomes for comprehensive agricultural equipment assessment.

Accurately measuring power transmission shafts forms the foundation of proper dynamometer testing on agricultural tractors, guaranteeing safe operation and reliable power output evaluation.

Precise shaft measurement techniques directly influence test accuracy and equipment longevity, making this process critical for professionals seeking consistent, repeatable results. Technicians must comprehend PTO shaft maintenance principles and measurement protocols to establish baseline data before connecting to dynamometer systems.

Essential measurement practices include:

Proper shaft evaluation prevents misalignment issues, enhances power transmission efficiency, and guarantees technicians extract maximum diagnostic value from agricultural dynamometer testing protocols. Selecting quality accessories and parts specifically engineered for your dynamometer model further optimises system performance and extends equipment reliability during demanding agricultural testing operations.

When agricultural equipment manufacturers and independent testing facilities evaluate tractor performance, they rely on standardised protocols that guarantee consistent, comparable results across different makes and models.

These performance benchmarks establish uniformity through OECD codes and Nebraska Tractor Test Lab methodologies, ensuring rigorous testing methodologies applicable worldwide.

The compulsory main PTO test evaluates tractors at multiple critical points: maximum engine speed, normal PTO speeds of 540 or 1000 rpm, peak power speed, and maximum torque.

Load application follows the engine operating curve at full throttle, with dynamometers applying calibrated braking forces through the PTO shaft.

Regular software updates ensure that dynamometer systems maintain accuracy and compatibility with evolving tractor technologies and testing standards.

This standardised approach enables operators and engineers to compare data reliably across different tractor makes and models, establishing performance benchmarks that inform purchasing decisions and validate engineering specifications consistently.

The foundation of modern tractor performance evaluation rests on extensive drawbar and hydraulic testing, a dual-assessment approach that measures both the pulling power available at the hitch and the auxiliary hydraulic systems that operate implements.

Key Testing Parameters:

Nebraska Tractor Test Laboratory performs mixed-mode evaluations, combining drawbar, PTO, and hydraulic assessments simultaneously.

This integrated approach guarantees operators comprehend complete power availability, enabling proper implement matching and fuel efficiency optimisation for agricultural operations.

As tractors and agricultural machinery have grown more complex, testing approaches have evolved dramatically to keep pace with technological advancement.

Modern test beds now integrate multiple sensor types, enabling thorough performance evaluation in single sessions. Sensor fusion combines data from load cells, environmental monitors, and positioning systems, creating a complete snapshot of machinery behaviour under real operating conditions.

Real-time monitoring capabilities allow technicians to observe performance metrics instantly, identifying issues before they become critical problems.

Multi-axis force sensors capture pushing, pulling, and lateral forces simultaneously, while environmental data collection tracks temperature and humidity alongside operational parameters.

Professional expert calibration techniques ensure that all integrated measurement systems deliver precise and reliable data for accurate machinery performance assessment.

This integrated approach delivers consistent, scientifically valid results that support accurate machinery enhancement and operational safety verification across diverse agricultural applications.

How does one choose the right dynamometer when agricultural operations demand precision, reliability, and cost-effectiveness? The decision requires evaluating specific operational needs, budget constraints, and testing requirements.

Key Selection Factors:

Agricultural operations benefit from grasping these distinctions.

Portable units suit quick diagnostics and mobile operations, while stationary hydraulic systems excel in permanent workshop environments where precision testing justifies higher initial costs.

Selecting appropriately maximises testing reliability and operational efficiency for professional operations.

Fleet operators are throwing money away. Dynos reveal what road tests miss—and how much you’re losing.

Water testing won’t reveal what dyno testing exposes. Learn why engine builders skip this step at their peril.

Tractor performance tests reveal what manufacturers won’t tell you. See how dynamometer data exposes hidden inefficiencies in your equipment.

Diesel engine testing mistakes cost thousands monthly. Learn what separates thriving operations from regulatory nightmares.

Build a diesel dyno empire while most workshops fail—here’s what separates winners from the rest.

Most dyno operators ignore this one calibration step—and it’s costing them thousands in poor data.

Force and torque aren’t opposites—they work together in ways most people misunderstand. Learn how this relationship transforms machine performance.

Your engine’s power never reaches your wheels—here’s why and what it costs you.