Fleet Fuel Efficiency: Optimising Trucks With Dynos

Fleet operators are throwing money away. Dynos reveal what road tests miss—and how much you’re losing.

Your fleet’s fuel budget is haemorrhaging money—and your standard monitoring tools can’t see where it’s going. Dynamometers expose the invisible performance drains that road tests miss: friction, drag, and mechanical losses quietly eating into profits. While competitors waste fuel chasing guesses, data-driven operators are implementing precision optimisation strategies that generate measurable savings. The real question isn’t whether your operation can improve—it’s how many percentage points you’re currently leaving on the table.

Because fuel costs represent one of the largest operational expenses in commercial fleet management, grasping where energy is being wasted becomes critical to profitability.

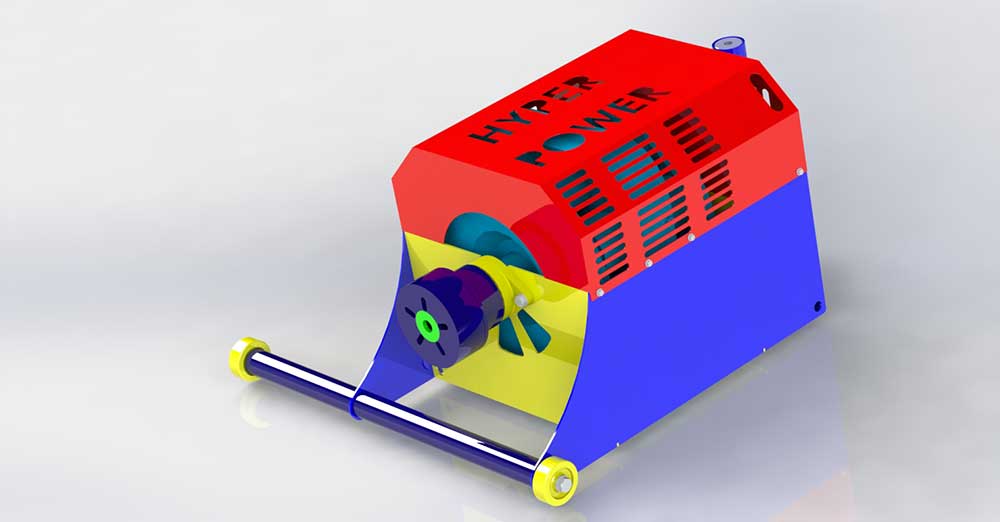

Dynamometers pinpoint fuel inefficiency sources with precision, revealing hidden parasitic losses that road testing alone cannot capture. Through dyno performance metrics, technicians measure torque and power drops that indicate drag, friction, and combustion inefficiencies consuming fuel unnecessarily.

Engine dynamometers isolate fuel flow and throttle response during low-load cycles, exposing waste during idle and light-duty operations. Our advanced testing methodologies ensure accurate identification of these inefficiencies across all operating conditions.

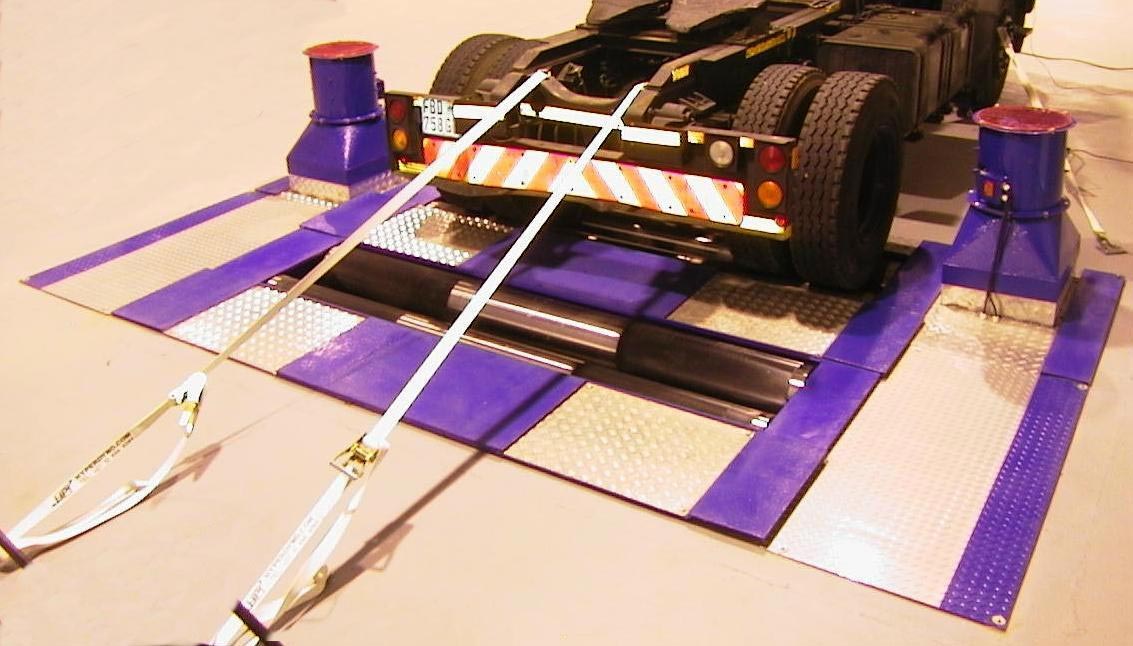

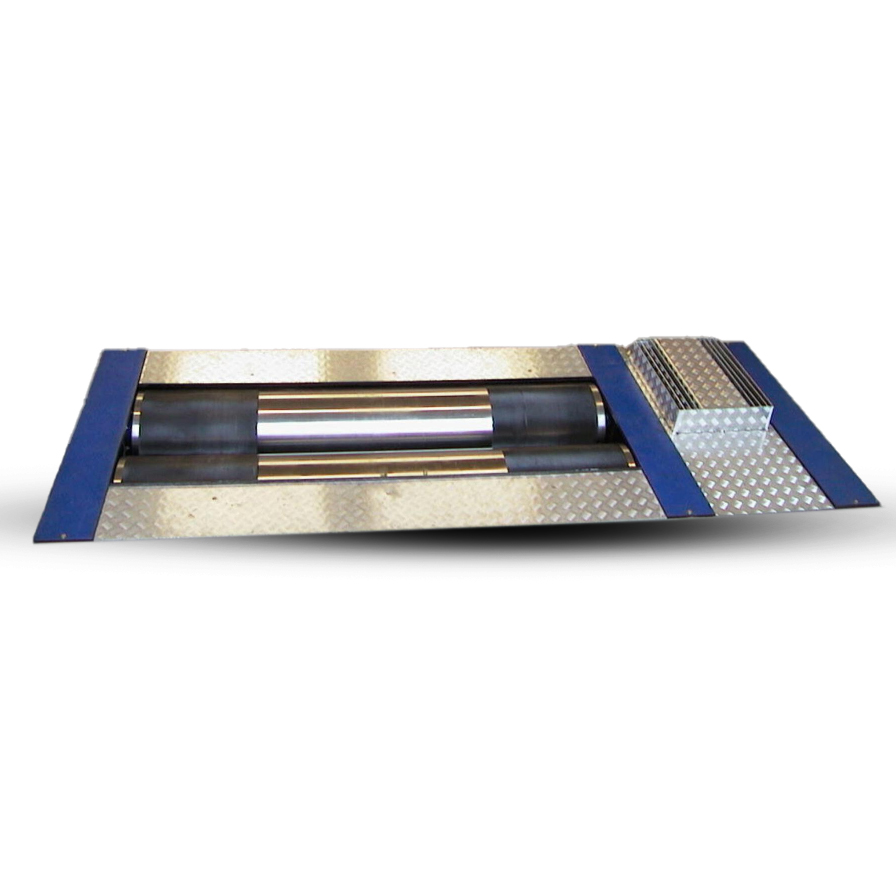

Chassis dynamometers simulate real-world driving conditions, capturing how drivetrain interactions affect overall fuel consumption across varied payloads.

Technologies like cylinder deactivation systems reduce active cylinders during low-demand periods, minimising energy waste. Real-world validation through standardised testing protocols over extended mileage confirms that theoretical improvements translate into consistent, measurable fuel economy gains in actual fleet operations.

Dyno testing validates these improvements, demonstrating measurable fuel economy gains before fleet implementation.

While dynamometers reveal hidden inefficiencies within engine and drivetrain systems, telematics platforms provide the real-world operational structure needed to validate those findings across an entire fleet.

| Data Source | Metrics Captured | Real-World Application | Baseline Value |

|---|---|---|---|

| Telematics Integration | Fuel consumption, trip distance, idle time | Fleet-wide efficiency tracking | Establishes operational baseline |

| Chassis Dynamometer | Torque, power output, engine efficiency | Controlled performance validation | Identifies performance deviations |

| Combined Analysis | Complete efficiency overview | Fuel waste reduction strategies | Accurate data accuracy verification |

| Remote Diagnostics | System anomalies, maintenance needs | Proactive issue resolution | Enhanced efficiency metrics |

Telematics integration connects factory-installed hardware to unified data platforms, eliminating manual data collection. Dyno testing under controlled conditions validates engine performance, while real-world telematics data confirms fuel efficiency patterns. This combined approach builds thorough baselines, enabling fleet managers to identify specific improvement opportunities and track progress systematically. Our cutting-edge software solutions integrate with industry platforms to streamline data analysis and performance tracking. Geotab processes 100 billion data points daily from connected vehicles, providing the comprehensive insights needed to optimise fleet performance across diverse operating conditions.

Driver behaviour represents the most controllable variable in fleet fuel consumption, with individual actions determining whether vehicles operate at peak efficiency or waste thousands annually.

Idle time accumulation and aggressive driving patterns—including rapid acceleration, hard braking, and sharp turns—compound fuel losses across entire operations, making systematic tracking of these behaviours essential for cost reduction. Long-haul trucks idling for an estimated 6 hours per day consume approximately 1 gallon of fuel per hour, resulting in over 6 billion gallons of fuel lost annually across the industry due to unnecessary idling. Real-time performance evaluations through advanced diagnostics can identify these inefficient patterns before they accumulate into significant losses.

Comprehending how specific driving habits translate directly into measurable fuel expenses enables fleet managers to implement targeted interventions that yield measurable returns on investment.

Every hour that a Class 8 truck idles, it consumes 0.8 gallons of diesel fuel—a seemingly small amount that compounds into substantial financial losses across fleets and seasons.

A single vehicle idling overnight for 8 hours burns through 6.4 gallons, translating to approximately 1,200 gallons yearly and £3,800 in wasted expenses.

Fleet-wide consequences prove staggering.

Twenty-five trucks idling just 2 hours daily incur £38,400 annually in fuel waste over 300 operating days.

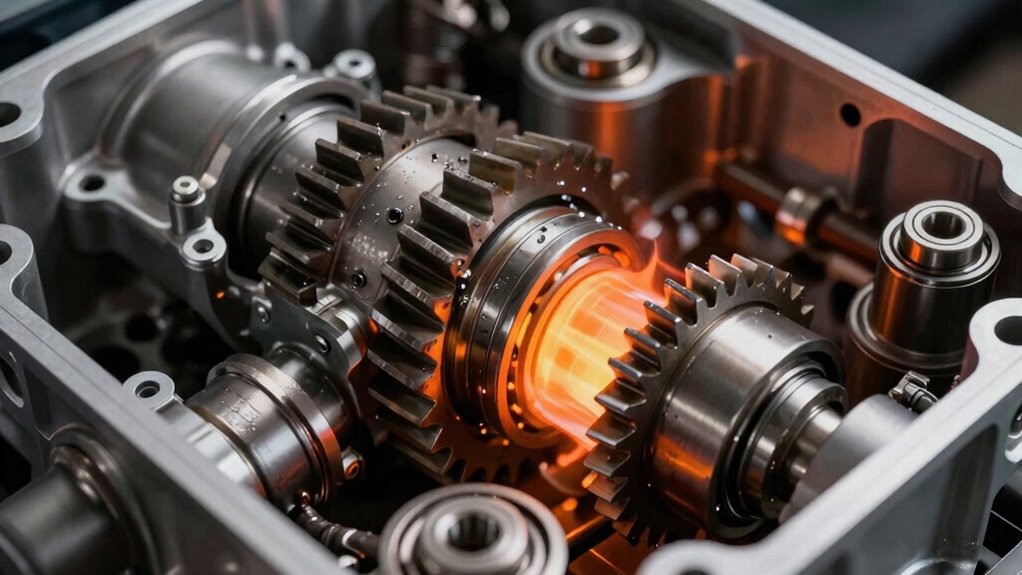

Beyond fuel costs, excessive idle fuel consumption accelerates engine wear, equating to 25-30 miles of deterioration per idle hour, triggering premature maintenance on injectors, pistons, and emissions systems. Implementing idle reduction technologies such as diesel APUs and electric APUs can significantly mitigate these maintenance costs. Regular dynamometer testing ensures your engines maintain optimal performance and detect wear patterns early.

Understanding idle time impact enables fleet managers to implement targeted idling strategies, leveraging telematics and geo-fenced shutdown prompts that reduce idle by 10-15 percent, directly improving profitability.

Beyond the stationary losses from idle time, aggressive driving behaviours—speeding, rapid acceleration, and hard braking—create a fluid drain on fleet fuel economy that rivals or exceeds idling costs.

Aggressive acceleration alone reduces fuel economy by 15-30% at motorway speeds, while hard braking contributes similar losses of 15-30% on open roads. These habits account for approximately 25% of total fleet fuel waste, translating to thousands in annual losses per truck.

The financial impact compounds through increased maintenance expenses and accelerated engine wear. In 2020, speeding-related crashes alone cost society over 40 billion dollars in economic losses, demonstrating the broader financial consequences of aggressive driving patterns.

Drivers exhibiting aggressive patterns typically show higher crash and citation rates, correlating directly with heightened operational costs. Professional driver behaviour coaching programmes leverage continuous support and telematics data to optimise fleet performance and reduce fuel waste through structured training methodologies.

Video telematics systems identify these habitual patterns, enabling targeted coaching programmes that realign driver behaviour toward fuel-conscious techniques, recovering the 5-10% efficiency gains achievable through moderate driving practices.

When fleet operators combine advanced route efficiency software with dynamometer testing, they reveal a powerful methodology for identifying and validating fuel efficiency gains across their entire operation.

Route efficiency improvements deliver measurable results, with ideal stop sequencing reducing daily mileage from 620 to 450 miles per truck, yielding £18,250+ annual fuel savings per vehicle.

Ideal stop sequencing cuts daily mileage to 450 miles, delivering £18,250+ annual fuel savings per vehicle.

Dyno testing establishes baseline performance metrics, measuring pre-efficiency fuel economy before implementing changes. Post-efficiency verification confirms actual gains, with dyno-simulated conditions validating improvements ranging from 8.0 to 9.5 MPG in newer models.

This integrated approach alters route optimisation from theoretical benefit to proven outcome, ensuring operators achieve sustained fuel savings aligned with real-world performance data and operational conditions. By partnering with providers offering comprehensive support for dynamometer systems, fleet operators gain access to technical expertise that ensures precise calibration and reliable testing throughout their optimisation journey.

Fleet operators face a critical challenge: vehicles that appear functional on the surface often harbour hidden inefficiencies that drain fuel budgets and reduce uptime. Real-time monitoring systems detect these problems before they escalate, converting reactive repairs into planned maintenance events. Hyper Power’s advanced diagnostic tools can identify these hidden inefficiencies with precision, ensuring your fleet maintains peak performance.

| Performance Indicator | Monitored Via | Impact on Fuel | Detection Method |

|---|---|---|---|

| Oil Temperature | Sensors | 2% efficiency loss | Continuous tracking |

| Tire Pressure | Telematics | 3-5% fuel waste | Mechanised alerts |

| Engine Performance | Diagnostics | Variable loss | Predictive analytics |

| Brake Wear | Real-time data | Drag increases costs | Condition-based scheduling |

| Idle Time | Vehicle telematics | Significant waste | Analytics review |

Predictive analytics identify excessive idle time and component degradation, triggering maintenance scheduling before catastrophic failure occurs. Companies implementing these systems report 25% uptime increases and 20-25% maintenance cost reductions, allowing fleets to maintain peak fuel efficiency while extending asset lifespan.

Most fleet operators recognise that fuel costs represent one of their largest controllable expenses, yet many lack the visibility needed to identify where inefficiencies originate.

Fuel benchmarking establishes baseline performance metrics by comparing individual vehicle data against industry standards and historical performance.

Baseline performance metrics establish fuel benchmarking by comparing vehicle data against industry standards and historical performance.

Modern telematics systems and fleet management software aggregate fuel consumption data, revealing efficiency metrics across your entire operation.

This granular visibility enables vehicle-by-vehicle analysis, identifying underperformers that require maintenance attention or driver coaching.

Benchmarking fuel efficiency internally tracks performance degradation over time, signalling maintenance issues or behavioural patterns requiring intervention.

External benchmarking against peer fleets establishes realistic performance targets, positioning your operation competitively.

Dynamometer testing provides precise performance validation of fuel efficiency improvements before fleet-wide implementation, ensuring measurable results across your operation.

Organisations implementing systematic fuel benchmarking programmes typically achieve 15% consumption reductions.

Strategic analysis alters raw data into actionable understandings, driving measurable cost savings and operational improvements across your fleet.

Benchmarking establishes where inefficiencies exist, yet identifying the problem represents only half the challenge—converting that diagnostic data into measurable savings requires a systematic approach.

Dyno testing reveals specific tuning opportunities: air-fuel ratios, injection timing, and enhancement levels that directly impact fuel consumption. Professional fuel tuning and engine calibration address these findings systematically, optimising parameters across varying loads and RPM ranges.

The action plan begins with baseline dyno data, establishing horsepower, torque, and efficiency metrics before modification. Technicians then implement targeted engine calibration adjustments, validating each change through post-tune dyno sessions. Regular software updates ensure your dynamometer maintains peak accuracy throughout the validation process.

Real-world speed simulation up to 310 mph ensures tuning effectiveness across actual operating conditions.

Fleet operators track results through telematics systems, measuring idle time reduction and fuel economy improvements. This data-driven approach alters diagnostic understandings into tangible cost reductions, protecting long-term vehicle durability while maximising operational efficiency.

Fleet operators are throwing money away. Dynos reveal what road tests miss—and how much you’re losing.

Water testing won’t reveal what dyno testing exposes. Learn why engine builders skip this step at their peril.

Tractor performance tests reveal what manufacturers won’t tell you. See how dynamometer data exposes hidden inefficiencies in your equipment.

Diesel engine testing mistakes cost thousands monthly. Learn what separates thriving operations from regulatory nightmares.

Build a diesel dyno empire while most workshops fail—here’s what separates winners from the rest.

Most dyno operators ignore this one calibration step—and it’s costing them thousands in poor data.

Force and torque aren’t opposites—they work together in ways most people misunderstand. Learn how this relationship transforms machine performance.

Your engine’s power never reaches your wheels—here’s why and what it costs you.