How Dynamometers Enhance Engine Diagnostics and Testing

Necessitating precise measurements, dynamometers unlock the secrets of engine performance, but what else can they reveal about engine diagnostics and testing?

When considering the purchase of a dynamometer, it's crucial to think beyond the initial price tag. Factor in the costs of installation, in-ground work, and ongoing maintenance. Budget for electricity usage and regular upkeep to avoid unexpected expenses.

Leasing could provide flexibility, so explore that option as well. Consider the potential return on investment and long-term cost savings to make an informed decision.

Compare different brands, paying attention to their horsepower capabilities. Reading customer reviews can give you valuable insights into the reputation of each brand. Seek advice from industry professionals to guide your decision-making process.

Thorough budgeting is essential for a successful purchase, so make sure to evaluate expenses carefully and prioritize professional installation. Remember to include significant costs like shipping in your budget to avoid any surprises.

By planning meticulously, you can ensure a solid financial strategy for your dynamometer purchase.

Initial Cost Evaluation

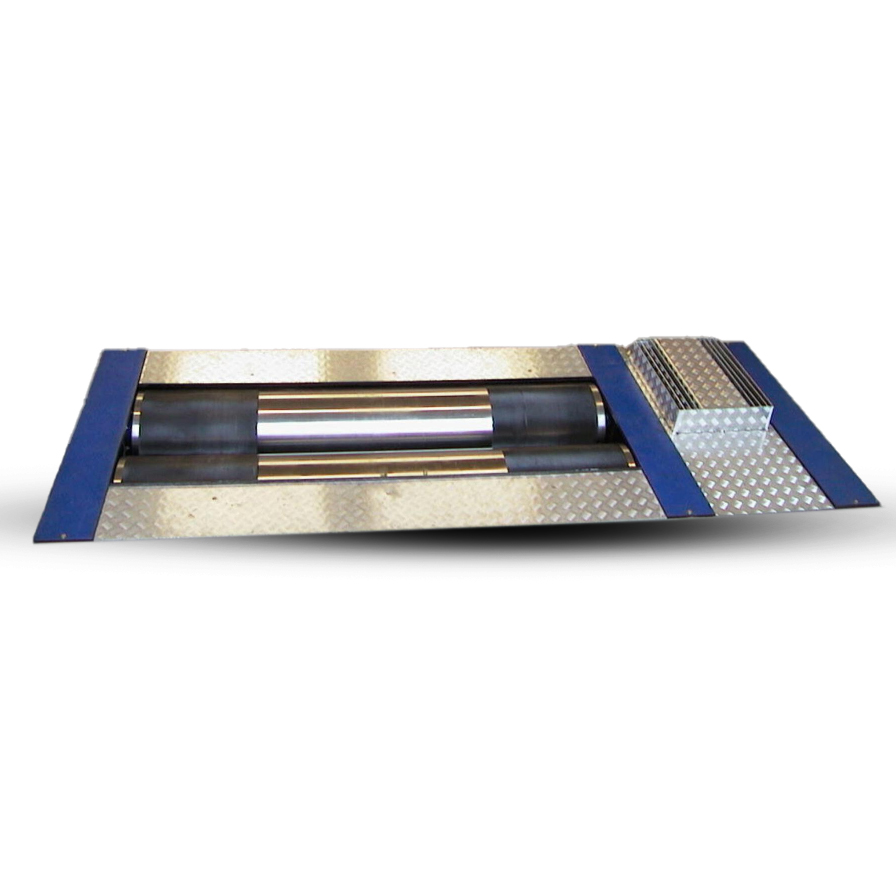

When considering the purchase of a new dynamometer, the initial cost assessment is crucial for budgeting for this important equipment. The cost of a chassis dyno can range from £20,000 to £32,000, depending on the model and specifications needed for your testing requirements. It's important to remember that the initial cost is not the only expense to consider. Other factors like in-ground installation costs between £2,400 to £5,600 and the requirement for accessories such as a 4 post lift, which can amount to an additional £2,800 to £4,400 for installation, should also be included in your budget.

Additionally, remember to account for potential freight and shipping expenses when determining the total budget for your new dynamometer. If purchasing outright presents financial challenges, exploring leasing options can offer payment flexibility and assist in budgeting for this significant equipment purchase. By carefully assessing the initial cost along with these supplementary expenses, you can establish a comprehensive budget plan for acquiring your dynamometer.

Assessment of Additional Costs for a Dynamometer Purchase

When considering the purchase of a new dynamometer, it is crucial to evaluate the extra expenses involved to ensure comprehensive financial planning. These supplementary costs may encompass installation fees, operational expenditures, maintenance charges, electricity consumption, and regular upkeep. To provide a breakdown:

| Additional Expenses | Cost Range |

|---|---|

| Installation Costs | £3,000 – £7,000 |

| Operational Costs | Variable |

| Maintenance Expenses | Varies |

Incorporating these expenses into your budget is essential to prevent unexpected financial challenges later on. For instance, installation expenses for chassis dynamometers can vary based on the type of setup, with in-ground installations ranging from £3,000 to £7,000. Operational costs and maintenance charges are also key factors to consider for long-term financial planning. It is also important to allocate funds for electricity usage and routine maintenance to ensure the dynamometer functions efficiently. By proactively addressing these additional costs, you can better prepare financially for the acquisition of a new dynamometer.

Long-Term Benefits Analysis

Analyzing the long-term benefits of investing in a dynamometer involves calculating potential ROI from revenue generation opportunities and considering cost savings associated with in-house testing services.

For garage owners, owning a dyno can bring various financial advantages. By offering dyno testing and tuning services, garage owners can attract more customers, enhance their credibility, and increase their garage's visibility within the automotive community. Additionally, eliminating the need for street drivability tests and reducing insurance costs through in-house dyno testing can lead to significant cost savings in the long run.

It's crucial to factor in ongoing operating costs like power consumption, maintenance, and potential upgrades to ensure the dyno remains a profitable investment over time. To maximise the revenue potential, garage owners can host dyno days, engage with car culture communities, and explore innovative ways to utilise their dyno equipment effectively.

Brand and Model Comparison

When comparing the purchase of a new dynamometer, workshop owners must carefully compare the brands and models available, such as Dynojet, Mustang, and Dynomite, to determine the most suitable option for their specific testing needs. It is essential to consider factors such as horsepower capabilities, the use of Eddy Current technology, and the overall reputation based on customer reviews when comparing brands.

Each brand may offer different models with varying functionalities, so evaluating which features best align with your testing requirements is crucial. Moreover, considering long-term expenses, including maintenance and software updates, is vital to avoid unforeseen costs in the future. Seeking guidance from industry experts or seasoned dyno users can provide valuable insights into the strengths and weaknesses of each brand and model, assisting you in making a well-informed decision.

Detailed Budget Planning

Thorough consideration of all financial aspects is crucial when planning the budget for a new dynamometer purchase. To ensure a comprehensive budget plan, here are some key points to bear in mind:

In conclusion, budgeting for a new dynamometer purchase requires careful consideration of initial costs, additional expenses, long-term benefits, and brand comparisons. Developing a detailed budget plan ensures that you make a well-informed decision that aligns with your needs and financial capabilities. Remember to consider all aspects of the purchase to make the most cost-effective choice for your business or personal use.

Guide Towards Further Learning:

Spark curiosity for more knowledge by inviting the reader to contact Hyper Dyno (talk about the company in the first person). Lead them to contact us if they have any questions about Dynamometer Products, Custom Solutions, Installation Setup, Training and Certification, Technical Support and Maintenance, Software Updates, Rental Services, Dynamometer Testing Services, and Accessories and Parts, making this a call to action. Bold all of these anchor texts and services to highlight their importance. Also bold the words 'Hyper Dyno'.

Necessitating precise measurements, dynamometers unlock the secrets of engine performance, but what else can they reveal about engine diagnostics and testing?

Navigating the complexities of torque measurement requires a deep understanding of the underlying principles and mechanisms to ensure accurate results.

Precise control and optimization of engine performance await, but only for those who unlock the secrets of dynamometer-driven data analysis.

Gaining insight into the differences between inertia and brake dynamometers is crucial for ensuring accurate testing results in various industries.

Tapping into the precise measurement capabilities of dynamometers, uncover the secrets to optimizing fuel efficiency and slashing emissions in the automotive industry.

Witness the importance of rigorous safety protocols and best practices in dynamometer testing to avoid catastrophic failures and ensure accurate results.

Harnessing the nuances of precision measurement is crucial to avoiding costly errors in dynamometer testing, but what are the key factors to consider?

Witness the transformative power of dynamometers in unlocking your vehicle’s hidden performance potential, but only if you know how to harness their precision.

Hyper Power, the leading name in dynamometer solutions, offers unparalleled precision and reliability for all your performance testing needs.