Hydraulic Dynos: Applications in Heavy Industry Jobs

Hydraulic dynos prevent catastrophic field failures—but most heavy industry operators still skip this critical step. Learn why.

Inertia dynamometer testing is susceptible to various challenges that can significantly compromise the accuracy and reliability of test results.

Inconsistent testing conditions, temperature-related obstacles, and system inertia and power measurement issues can all lead to inaccurate data.

Moreover, uncontrolled CO levels, inadequate airflow, and heat buildup can further affect test outcomes.

To guarantee reliable and accurate testing, it is essential to address these common issues through precise temperature control, careful calibration, and standardized testing protocols.

By addressing these complexities, one can reveal the full potential of inertia dynamometer testing.

In the sphere of inertia dynamometer testing, inconsistent testing conditions pose a significant hurdle to obtaining accurate and reliable results.

Dyno testing, which measures power, torque, and acceleration, relies heavily on precise control over variables such as temperature, humidity, and atmospheric pressure.

Slight deviations in these conditions can substantially impact test outcomes, leading to inaccurate data and unreliable inferences.

Inertia testing, which involves measuring the rotational inertia of a component or system, is particularly sensitive to changes in testing conditions.

Temperature variations, for instance, can alter the material properties of the component being tested, affecting its inertia and, consequently, the test results.

Furthermore, inconsistent testing conditions can also lead to variations in the acceleration profiles of the dyno, which can further compromise the accuracy of the test data.

Maintaining consistent testing conditions throughout the testing process is vital to guarantee reliable and accurate results.

This can be achieved through careful control of environmental factors, precise calibration of testing equipment, and adherence to standardized testing protocols.

System inertia challenges pose significant obstacles to accurate power measurement in inertia dynamometer testing.

Specifically, errors in mass calculation, incorrect inertial force assumptions, and roller inertia effects can all contribute to inaccurate results.

These challenges must be addressed to guarantee reliable and precise measurements in transient testing scenarios.

Calculating mass accurately is critical in inertia dynamometer testing, as even slight errors can substantially impact power measurements and subsequent inferences about engine performance.

Inertia dyno testing relies on precise mass calculations to account for the mechanical inertia of the engine and test system, which affects measured power during transient tests. Failure to do so can lead to incorrect verdicts about engine performance, as incorrect mass calculations result in inaccurate power measurements.

The net power produced by the engine is partly used to overcome system inertia, and faster transient tests, for instance, result in less power available as flywheel power. Correcting for system inertia by calculating inertia power can approximate total power in steady-state conditions.

To verify accurate measurements, it is vital to consider the engine's response time to command inputs and sensor response times to changes in actual values when programming an automated test. Accurate calculation of system inertia enables engineers to obtain precise power measurements, leading to a more accurate outcome.

The dynamometer's drum, a massive rotating cylinder, stores a substantial amount of kinetic energy, which appreciably affects power measurements during transient tests.

This stored energy, known as system inertia, impacts the measured power output of an engine during acceleration tests. Faster transient tests result in less power available, as more energy is required to overcome system inertia. Comparing step tests with acceleration tests reveals a drop in measured power, highlighting the significance of system inertia on power output.

Correcting for system inertia through the calculation of inertia power can approximate total power in steady-state conditions, allowing for more accurate testing results.

A low-inertia test system, such as a dynamometer with a low-momentum absorber, can counteract system inertia effects, reducing the energy required to accelerate the system. This approach enables more precise measurements of engine power and torque, ensuring reliable results in acceleration tests.

System inertia challenges must be acknowledged and addressed to optimise dynamometer testing for accurate and reliable data.

As the dynamometer's rollers rotate, they introduce a significant amount of mechanical inertia, which compounds the effects of system inertia on power measurements.

This added inertia affects the accuracy of power measurements, particularly at lower engine speeds. The rollers' inertia contributes to the system's aggregate inertia, making it vital to examine its impact on power measurements.

To counteract the effects of roller inertia, it is essential to understand its implications on power measurements.

Uncontrolled CO levels jeopardise the integrity of inertia dynamometer test results, as they can substantially impact the accuracy of measured power during a dyno session.

Carbon monoxide is a critical variable that influences the combustion process, leading to variations in power output and affecting the steady state of the engine. This makes it challenging to achieve consistent results.

Uncontrolled CO levels also affect the validity of testing methods, introducing additional variables caused by changes in air density and oxygen availability.

These variables lead to inconsistent power measurements, compromising the reliability of the test data. To guarantee accurate results, a controlled testing environment is vital, where CO levels are monitored and governed.

This minimises the impact of CO on measured power, ensuring that test results accurately reflect the engine's performance.

Inaccurate engine temperature readings can substantially impact the accuracy of power and torque measurements during inertia dynamometer testing.

Temperature control issues and temperature variance effects can lead to inconsistent and unreliable results, highlighting the importance of monitoring and controlling engine temperature throughout the testing process.

Failure to do so can result in misleading data, underscoring the need for precise temperature control to guarantee accurate and reliable results.

Temperature Control Issues

During engine testing, I have witnessed the substantial impact of temperature control issues on engine performance and power output.

Even a slight deviation in engine temperature results in inaccurate readings, which notably affect the test results. A 10°C increase in engine temperature results in a 2-3% decrease in power output. This highlights the significance of accurate temperature control in ensuring reliable test results.

To counter temperature control issues, it is vital to:

This approach ensures accurate temperature readings, which in turn maintain optimal engine performance and power output.

Engine temperature variance is a vital factor to consider when conducting inertia dynamometer testing, as even slight deviations can substantially influence test results.

A 10°C change in engine temperature can result in a 2-3% change in power output, making it imperative to maintain a consistent temperature throughout the testing process.

Inertia dynos are affected by temperature changes in the engine oil and coolant, which alter the engine's operating parameters and power output during testing. Failure to control engine temperature leads to inconsistent test results, making it difficult to accurately compare data from different test sessions.

Temperature variance also affects the air density in the test cell, which further impacts power output readings.

To mitigate these effects, it is essential to maintain a consistent engine temperature, typically between 80°C to 90°C, and ensure good airflow in the test cell to guarantee accurate and reliable test results. This ensures engineers can guarantee their engine dyno testing yields precise and comparable data.

A significant consideration in inertia dynamometer testing is the varying rates of acceleration employed, which can substantially influence power output readings.

Comparing tests with different acceleration rates can lead to inaccurate power output readings, as the rate of acceleration affects the measurement of power. Failing to control the rate of acceleration during testing can result in inconsistent results, making it difficult to accurately compare power output between different tests.

To guarantee accurate results, understanding the impact of acceleration rate on power output is crucial.

A 10 per cent change in acceleration rate can result in a 2-3 per cent change in measured power output.

Using a load cell to measure the force applied to the dyno roller helps to offset the effects of differing acceleration rates. A standardized acceleration rate should be used for all tests to guarantee consistent results.

The rate of acceleration must be carefully regulated during testing to minimize variability.

The accuracy of inertia dynamometer testing relies heavily on precise measurements, making the calibration of the load cell using verified weights a vital aspect that cannot be overlooked.

Failing to calibrate the load cell with verified weights leads to inaccurate power readings, as uncalibrated flywheels used as weights introduce significant errors. Regular dyno calibration is vital, guaranteeing that the load cell and other sensors provide accurate data, fundamental for reliable results.

A set of verified weights is necessary for calibration to guarantee accurate measurement of the force applied to the rollers, directly affecting power output calculations.

Ignoring the importance of accurate weight calibration results in power readings that are off by as much as 10-15%, rendering test results useless for comparison or tuning purposes. To maintain the accuracy and reliability of test results, calibration must be performed regularly, ideally every 1-3 months, depending on the frequency of use and the type of dyno.

In the high-stress environment of inertia dynamometer testing, heat and airflow issues can profoundly impact test results, often going unnoticed until it is too late.

Heat buildup can substantially alter test outcomes, leading to inaccurate data and wasted time. Inadequate airflow can intensify heat issues, causing engines to overheat and potentially leading to costly damage.

To counteract these issues, proactive measures are crucial. Consider the following:

Common Issues with Inertia Dynamometer Testing and Solutions

At Hyper Power, we understand the importance of accurate and reliable inertia dynamometer testing in evaluating internal combustion engine performance. However, several common issues can affect test results. This article highlights these problems and provides solutions to alleviate their impact.

Inconsistent Testing Conditions

Inconsistent testing conditions can lead to unreliable results. Factors such as ambient temperature, humidity, and air pressure can influence engine performance. To address this, testing should be conducted in a controlled environment with standardised conditions. If you have any questions about our Custom Dyno Solutions, Installation and Setup, or Technical Support and Maintenance, please contact us.

System Inertia Challenges

Inertia dynamometers can introduce system inertia, which affects engine performance. This can be overcome by using a dynamometer with low system inertia or compensating for inertia in the test setup. Our Training and Certification programme can help you navigate these challenges.

Uncontrolled CO Levels Impact

Uncontrolled CO levels can affect engine performance and emissions. CO levels should be monitored and regulated during testing to guarantee accurate results. Our Diagnostics and Performance Analysis services can help you identify and address CO level issues.

Inaccurate Engine Temperature

Inaccurate engine temperature measurement can lead to incorrect test results. Engine temperature should be measured using accurate and reliable methods, such as thermocouples or resistance temperature detectors. Our Software Updates and Upgrades can ensure your equipment is equipped with the latest temperature measurement technology.

Differing Acceleration Rates

Differing acceleration rates can affect engine performance and emissions. Standardised acceleration rates should be used to guarantee consistent results. Our Rental Services can provide you with the necessary equipment to achieve standardised acceleration rates.

Unverified Weights and Calibration

Unverified weights and calibration can lead to inaccurate results. Weights and calibration should be verified regularly to guarantee accuracy. Our Accessories and Parts can help you maintain accurate weights and calibration.

Mitigating Heat and Airflow Issues

Heat and airflow issues can affect engine performance and emissions. Proper cooling systems and airflow management should be implemented to alleviate these issues. Our Dynamometer Testing Services can help you identify and address heat and airflow issues.

In summary, common issues in inertia dynamometer testing can be alleviated by controlling testing conditions, addressing system inertia, monitoring CO levels, guaranteeing accurate engine temperature measurement, standardising acceleration rates, verifying weights and calibration, and managing heat and airflow. By addressing these issues, reliable and accurate test results can be achieved. If you have any questions or concerns, please contact Hyper Power.

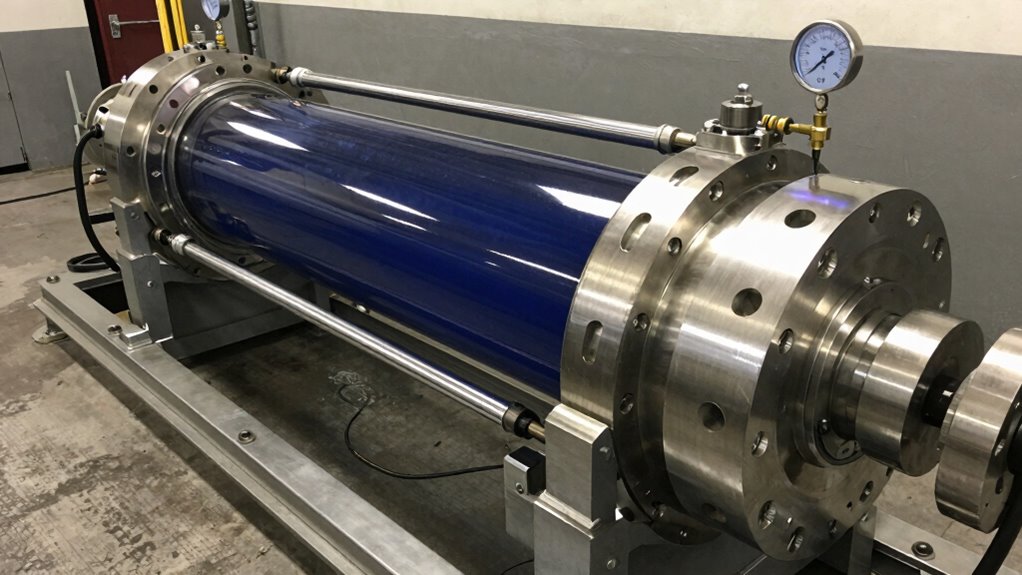

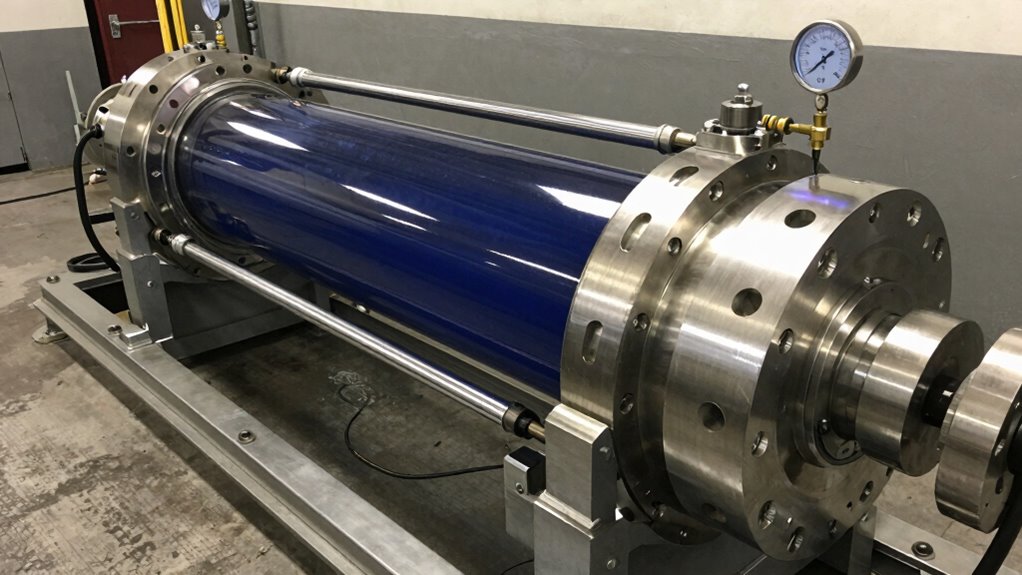

Hydraulic dynos prevent catastrophic field failures—but most heavy industry operators still skip this critical step. Learn why.

Most diesel dyno operators ignore this—and it costs them thousands in failed runs and wasted data.

Stop wasting money on road testing. One dyno investment eliminates comebacks, builds loyalty, and outpaces competitors. Here’s why your workshop needs it.

Diesel turbo lag isn’t inevitable—modern dyno diagnostics reveal the hidden culprits stealing your power. Find out what your engine is hiding.

Fleet operators are throwing money away. Dynos reveal what road tests miss—and how much you’re losing.

Water testing won’t reveal what dyno testing exposes. Learn why engine builders skip this step at their peril.

Tractor performance tests reveal what manufacturers won’t tell you. See how dynamometer data exposes hidden inefficiencies in your equipment.

Diesel engine testing mistakes cost thousands monthly. Learn what separates thriving operations from regulatory nightmares.

No posts found!