Hydraulic Dynos: Applications in Heavy Industry Jobs

Hydraulic dynos prevent catastrophic field failures—but most heavy industry operators still skip this critical step. Learn why.

Dynamometers play a vital role in fuel efficiency testing as they accurately simulate real-world driving conditions and measure fuel consumption.

This enables the precise evaluation of a vehicle's environmental footprint and operating costs. They provide reliable and repeatable test results, allowing for the identification of opportunities to optimise fuel efficiency and reduce emissions.

Controlling torque and speed, dynamometers accurately capture fuel consumption data under diverse load conditions, providing valuable insights into an engine's performance.

As the pursuit of fuel efficiency continues to evolve, the importance of dynamometers in engine testing and calibration will only continue to grow, revealing new opportunities for innovation and improvement.

Most modern engine testing facilities rely on dynamometers to accurately measure engine power output, and for good reason.

Direct measurement of engine power enables dynamometers to avoid transmission or driveline losses, ensuring accurate and reproducible results.

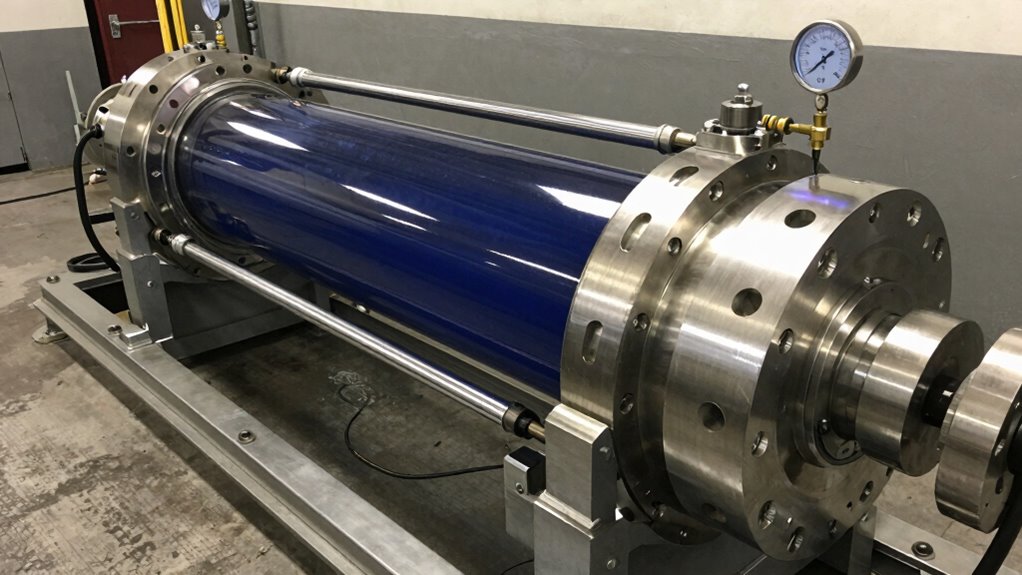

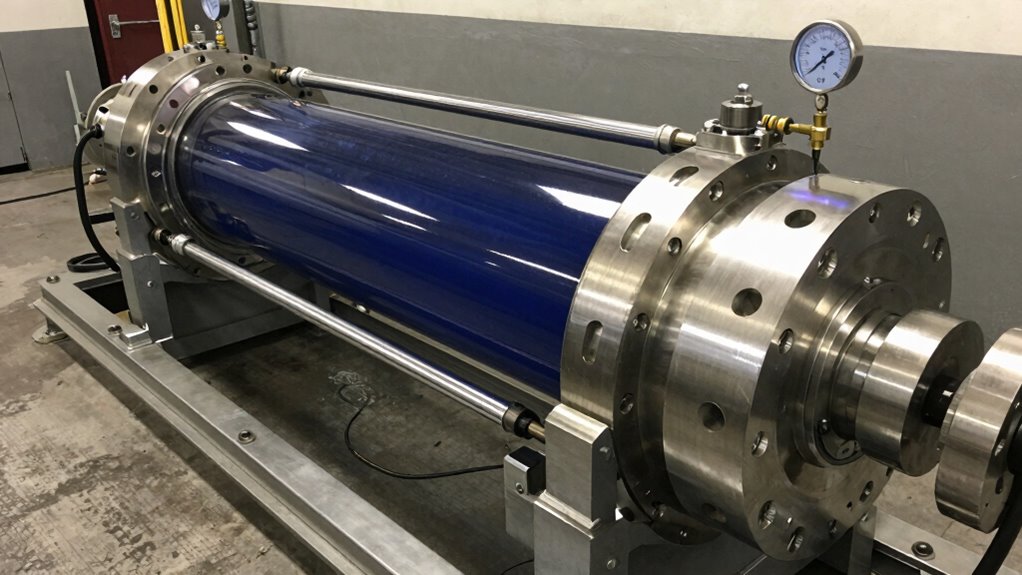

A dynamometer-based engine test cell typically comprises multiple measurement systems and equipment, including sensors, control systems, and data acquisition systems.

This setup enables precise measurement of power and torque output, in addition to other critical engine performance parameters.

Dynamometers operate on the principle of measuring force and power output, similar to a spring scale.

They can be classified into different types, including absorption, transmission, motoring, chassis, and inertia dynamometers.

Transient dynamometers, in particular, are capable of simulating real-world driving scenarios by exerting and absorbing specified loads under transient operating conditions.

The accuracy and repeatability of engine dynamometer tests are remarkably high, making them crucial tools in the automotive industry for fuel efficiency testing and engine development.

Engineers can tap into the full potential of engine testing, ultimately leading to more efficient and environmentally friendly vehicles, if they grasp the principles of dynamometers.

Accurate measurement of fuel efficiency is a pivotal aspect of engine testing, as it directly impacts the environmental footprint and operating costs of vehicles.

Dynamometers play a critical role in simulating real-world driving conditions and accurately capturing fuel consumption data, enabling precise fuel efficiency measurements.

Dynamometers test engines under different loads, allowing for precise control over torque and power output.

This enables engineers to measure fuel economy and fuel efficiency with high accuracy.

The test results obtained from dynamometers are reliable and repeatable, providing valuable insights into an engine's performance.

Some key benefits of using dynamometers in fuel efficiency testing are precise measurement of fuel consumption and fuel economy, accurate simulation of driving conditions using driving simulators and load cells, and repeatable and reliable test results, ensuring consistent data for engine optimization.

Three critical aspects of simulating real-world driving conditions are essential for accurate fuel efficiency testing: load, gradient, and transient behaviour.

Replicating these factors enables dynamometers to provide a precise evaluation of a vehicle's fuel consumption and emissions. Chassis dynamometer testing, for instance, applies diverse loads to simulate uphill and downhill driving, allowing for an in-depth measurement of fuel consumption and emissions.

Transient dynamometers simulate real-world driving scenarios, exerting and absorbing specified loads to or from the engine under transient operating conditions. This facilitates the simulation of driving cycles, such as urban, rural, or highway driving, to assess fuel efficiency under different conditions.

Dynamometers accurately measure fuel consumption and emissions by controlling torque and speed, taking into account factors like rotational speed and load applied. Simulating real-world driving conditions, dynamometers provide valuable insights into a vehicle's performance, helping to identify areas for improvement and optimise fuel efficiency.

Engine calibration and optimisation are pivotal steps in releasing a vehicle's full potential, and dynamometers play a crucial role in this process.

Dynamometer testing enables precise calibration and optimisation of engine parameters, such as fuel injection timing and ignition timing, to optimise fuel efficiency and reduce emissions.

Some key benefits of engine calibration and optimisation using dynamometers include fuel efficiency improvements of up to 10% or more, depending on the engine type and application.

Advanced engine calibration techniques, such as model-based calibration and machine learning-based calibration, can be developed and validated.

Evaluation of alternative fuels and fuel blends is also possible, allowing for optimisation of engine calibration for these fuels and reducing greenhouse gas emissions.

Dynamometer testing optimises engine calibration strategies, including optimisation of fuel injection pressure, fuel rail pressure, and exhaust gas recirculation, resulting in improved engine performance and reduced emissions.

Manufacturers can guarantee their vehicles meet stringent fuel efficiency and emissions standards, while also providing a better driving experience for consumers.

A vehicle's overall performance is only as good as its weakest link, and chassis dynamometer testing identifies and refines every component's contribution to its total efficiency.

This exhaustive approach enables test vehicles to be evaluated as a whole, rather than focusing on individual components in isolation. Chassis dynamometer testing allows for performance testing under multiple load conditions, simulating real-world driving scenarios.

The dynamometer measures the entire vehicle's performance, including the drive system, energy systems, and other components, providing a complete picture of the vehicle's efficiency. Data acquisition systems collect and analyse data in real-time, allowing engineers to pinpoint areas for improvement.

Each component's contribution is refined, enabling the optimisation of the entire vehicle and leading to improved fuel efficiency and aggregate performance. This integrated approach guarantees that every component works in harmony, resulting in a more efficient and effective vehicle.

Most stringent emissions regulations necessitate the use of transient testing, a pivotal component of the emissions compliance process.

Transient dynamometers are designed to simulate real-world operating conditions, making them ideal for emissions compliance testing. They accurately replicate the dynamic load patterns of real-world driving, ensuring exhaust emission measurements accurately represent engine operation.

Transient dynamometers exert and absorb any specified load to or from the engine, replicating real-world operating conditions.

Engine dynamometer testing allows fine-tuning of the engine under optimum operating conditions, indispensable for meeting regulatory emissions standards. Accurate data acquisition is pivotal in transient testing, and advanced data analysis techniques are necessary to verify reliable results.

Transient testing is indispensable for ensuring that engines meet regulatory emissions standards, and dynamometers play a critical role in this process.

Accurate and reliable data on engine power and emissions are provided, helping engineers optimise engine performance for improved fuel efficiency and reduced emissions.

Advancing fuel efficiency with technology is pivotal for reducing emissions and optimizing engine performance.

Dynamometers play a paramount role in this pursuit by providing precise fuel consumption analysis, allowing for the development of effective emission reduction methods.

Through strategic application of advanced technologies, the automotive industry is making significant strides in reducing emissions and improving fuel efficiency.

Emission reduction methods play a vital role in this pursuit, with dynamometers at the forefront of this effort.

Engine dynamometer testing investigates impacts of driving styles and ambient conditions on emissions and fuel consumption, helping identify areas for improvement.

Transient dynamometers in emission certification testing simulate real-world driving conditions, ensuring engines are optimized for fuel efficiency in diverse scenarios.

Chassis dynamometer testing evaluates effects of different driving behaviours on emissions and fuel economy, providing valuable data for development of eco-friendly driving strategies.

Engine performance optimisation is a critical aspect of reducing emissions and improving fuel efficiency in the automotive industry.

Dynamometers provide accurate and reproducible results, allowing for precise measurement of engine power output and fuel consumption under different operating conditions. Transient dynamometers simulate real-world driving cycles, testing engine performance and fuel efficiency under realistic conditions, such as the Federal Test Procedure and the New European Driving Cycle.

Chassis dynamometers evaluate the impacts of driving behaviours on fuel economy and emissions, identifying areas for improvement in engine performance and fuel efficiency.

Manufacturers can optimise engine performance, improving fuel efficiency by up to 10% and reducing emissions and operating costs, through dynamometer testing. Optimising torque and power output enables engines to operate more efficiently, resulting in improved fuel efficiency and reduced emissions.

As fuel consumption analysis takes centre stage, dynamometers emerge as a crucial tool in evaluating the efficacy of fuel-saving technologies and components.

Simulating real-world driving conditions, dynamometers provide accurate and reliable data on fuel consumption, enabling the identification of opportunities to optimise fuel efficiency and reduce emissions.

This data is vital in the development of fuel-efficient technologies, as it allows researchers and manufacturers to refine their strategies and guarantee compliance with regulatory standards.

Dynamometers are utilised to test fuel-saving technologies, such as single wide and low rolling resistance tyres, and trailer aerodynamic components, which can lead to improved fuel efficiency in the transportation sector.

The US Environmental Protection Agency (EPA) relies on dynamometers to measure fuel economy and NOx emissions of heavy-duty trucks and engines, informing the development of fuel-efficient technologies.

Standardised protocols, such as the SAE J1321 protocol, guarantee consistency and comparability of results across different test facilities and vehicles, facilitating the advancement of fuel efficiency testing.

Understanding Dynamometer Principles

At Hyper Power, we understand the importance of dynamometers in fuel efficiency testing. These machines provide a controlled environment to measure the performance of vehicles and their engines. The principle behind dynamometers is to apply a load to the engine, simulating real-world driving conditions, and measure the resulting torque and power output. This allows our engineers to accurately assess the fuel efficiency of a vehicle under multiple operating conditions.

Measuring Fuel Efficiency Accurately

Our dynamometers enable precise measurement of fuel consumption, which is vital in determining a vehicle's fuel efficiency. By controlling factors such as speed, load, and temperature, our dynamometers guarantee that fuel efficiency tests are accurate and repeatable. This accuracy is necessary in comparing the performance of different vehicles and engines. If you have any questions about our Custom Dyno Solutions, please do not hesitate to contact us.

Simulating Real-World Driving Conditions

Our dynamometers can simulate a wide range of driving conditions, including urban, rural, and highway cycles. This allows our engineers to test vehicles under multiple scenarios, such as stop-and-go traffic, hill climbs, and cruising at high speeds. By simulating real-world driving conditions, our dynamometers provide a more accurate representation of a vehicle's fuel efficiency in everyday use. We offer Installation and Setup services to ensure that our dynamometers are correctly installed and set up for optimal performance.

Engine Calibration and Optimisation

Our dynamometers play a critical role in engine calibration and optimisation. By testing different engine configurations and calibrations, our engineers can identify the most fuel-efficient settings for a particular vehicle. This process enables the development of engines that are optimised for fuel efficiency, reducing emissions and fuel consumption. We provide Training and Certification programmes to ensure that our clients can operate our dynamometers safely and efficiently.

Chassis Dynamometer Testing Benefits

Chassis dynamometer testing offers several benefits, including the ability to test entire vehicles, rather than just engines. This allows our engineers to assess the impact of factors such as aerodynamics, tyre rolling resistance, and transmission efficiency on fuel efficiency. Moreover, chassis dynamometer testing enables the testing of hybrid and electric vehicles, which is not possible with traditional engine dynamometers. Our Technical Support and Maintenance team is available to assist with any issues that may arise during testing.

Transient Testing for Emissions Compliance

Our dynamometers are vital in transient testing, which involves simulating real-world driving scenarios to assess a vehicle's emissions performance. By testing vehicles under transient conditions, our engineers can guarantee compliance with emissions regulations, such as those set by the United States Environmental Protection Agency. We offer Software Updates and Upgrades to ensure that our dynamometers are always up-to-date with the latest testing protocols.

Advancing Fuel Efficiency With Technology

Advances in dynamometer technology have improved the accuracy and efficiency of fuel efficiency testing. Modern dynamometers can simulate complex driving scenarios, such as those involving regenerative braking and hybrid powertrains. Moreover, the integration of data acquisition systems and simulation software has enabled the development of more sophisticated testing protocols. Our Diagnostics and Performance Analysis services can help identify areas for improvement in your vehicle's fuel efficiency.

Conclusion

At Hyper Power, we understand the importance of dynamometers in fuel efficiency testing. Our dynamometers enable accurate measurement of fuel consumption, simulation of real-world driving conditions, and engine calibration and optimisation. We offer a range of services, including Rental Services, Dynamometer Testing Services, and Accessories and Parts, to support your fuel efficiency testing needs. If you have any questions, please contact us.

Hydraulic dynos prevent catastrophic field failures—but most heavy industry operators still skip this critical step. Learn why.

Most diesel dyno operators ignore this—and it costs them thousands in failed runs and wasted data.

Stop wasting money on road testing. One dyno investment eliminates comebacks, builds loyalty, and outpaces competitors. Here’s why your workshop needs it.

Diesel turbo lag isn’t inevitable—modern dyno diagnostics reveal the hidden culprits stealing your power. Find out what your engine is hiding.

Fleet operators are throwing money away. Dynos reveal what road tests miss—and how much you’re losing.

Water testing won’t reveal what dyno testing exposes. Learn why engine builders skip this step at their peril.

Tractor performance tests reveal what manufacturers won’t tell you. See how dynamometer data exposes hidden inefficiencies in your equipment.

Diesel engine testing mistakes cost thousands monthly. Learn what separates thriving operations from regulatory nightmares.

No posts found!