Hydraulic Dynos: Applications in Heavy Industry Jobs

Hydraulic dynos prevent catastrophic field failures—but most heavy industry operators still skip this critical step. Learn why.

Dynamometers are a vital tool for enhancing engine diagnostics and testing, providing accurate and precise measurements of an engine's performance.

They simulate real-world operating conditions, allowing engineers and technicians to identify areas for improvement, optimise engine design, and guarantee that engines meet performance and emissions standards.

Accurate calculation of torque, power, and rotational speed enables precise engine analysis, enabling technicians to diagnose issues with unparalleled speed and accuracy.

As a result, engine manufacturers and testers can optimise engine performance, reduce costs, and improve product quality, ultimately driving innovation and competition in the industry.

A dynamometer's primary function is to quantify the performance of an engine or rotating prime mover, measuring its torque and rotational speed to calculate power output and other key performance metrics.

This is achieved through applying a load to the engine, simulating real-world operating conditions, and measuring the engine's response to that load. The load can be varied to simulate different driving scenarios, allowing for an exhaustive understanding of the engine's performance under diverse conditions.

The data collected is essential in engine testing, enabling the identification of performance issues, optimisation of engine tuning, and improvement of total engine efficiency and reliability. Accurate measurement of torque, rotational speed, and power output makes dynamometers pivotal in the development and production of high-performance vehicles.

Engineers and technicians can tap the full potential of their engines, ensuring optimal performance and reliability, with a grasp of dynamometer fundamentals.

Torque, rotational speed, and power output are the fundamental metrics that define an engine's performance, and accurate calculation of these metrics is essential in guaranteeing the reliability and efficiency of the engine.

Engine dynamometers simulate real-world operating conditions, such as varying loads on the engine, and measure the corresponding torque and rotational speed.

This data is then used to calculate power output, a critical indicator of an engine's performance.

The accuracy of these calculations is dependent on the precision of the dynamometer testing equipment and the expertise of the testing personnel.

Accurate calculation of torque, power, and rotational speed enables engine manufacturers and testers to identify areas for improvement, optimise engine design, and guarantee that engines meet performance and emissions standards.

Ultimately, accurate calculation of engine performance metrics enables the development of more efficient, reliable, and environmentally friendly engines.

Engine testing necessitates a diverse range of dynamometers to accommodate the varying power outputs and specific testing requirements of different engines.

The type of dynamometer used substantially impacts the accuracy and reliability of the results in dyno testing.

Water brake dynamometers are ideal for higher power engine dynamometers, capable of testing engines that produce up to 10,000 horsepower.

Eddy current (EC) brake dynamometers, on the other hand, are better suited for lower power applications, typically testing engines that produce up to 1,000 horsepower.

AC regenerative dynamometers create a load and return power to the electrical grid, making them energy-efficient and suitable for testing high-performance engines.

Chassis dynamometers for vehicle testing are also available, allowing for precise control over the testing process.

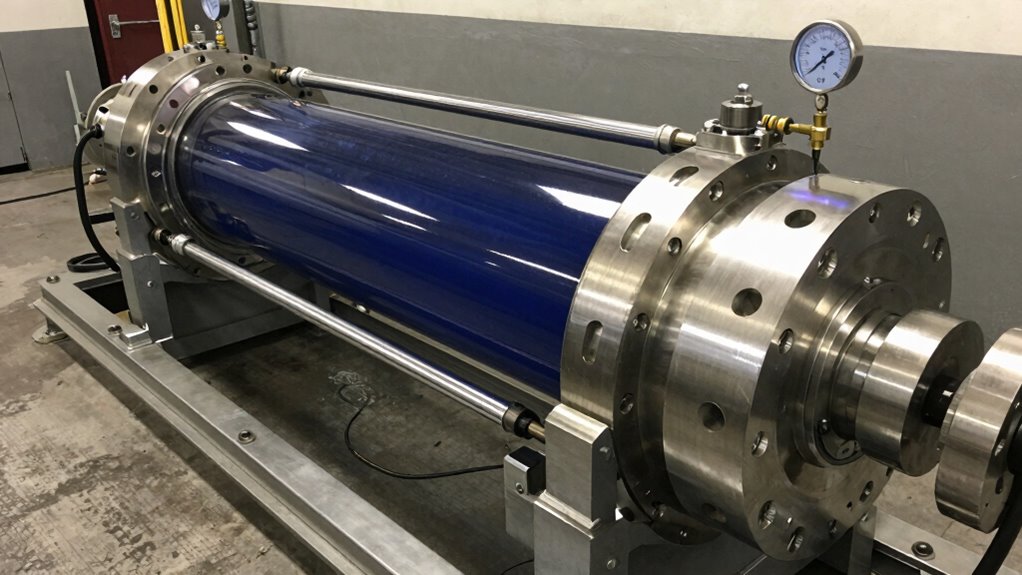

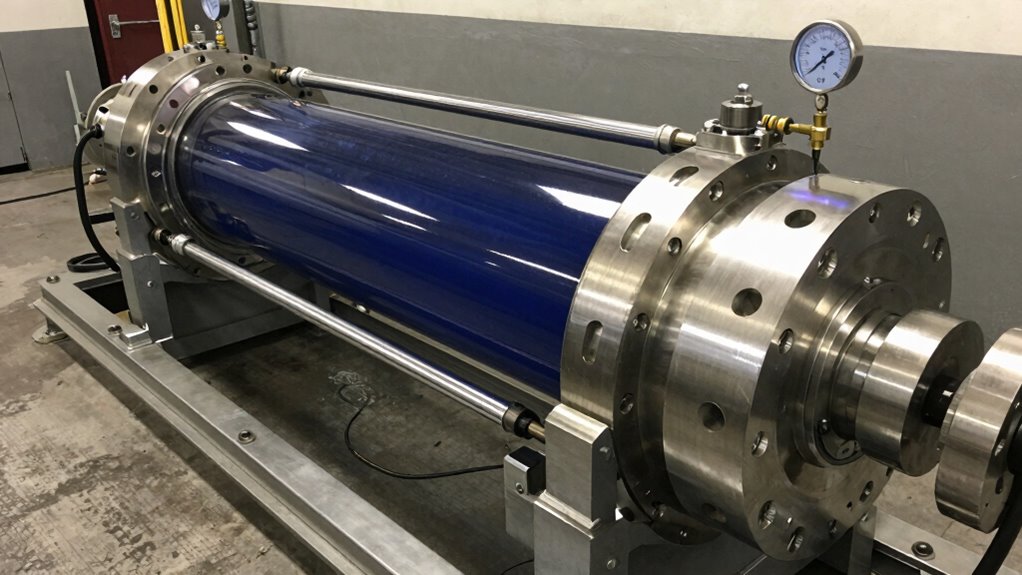

Hydraulic dynamometers and AC motoring dynamometers provide further options for testing large, heavy-duty engines and high-performance engines, respectively.

Selecting the right type of dynamometer optimises engine dynamometer measures, ensuring accurate and reliable results in dyno testing.

When it pertains to enhancing engine diagnostics, dynamometers play a vital role in providing accurate performance data, enabling real-time engine analysis, and offering precise load control.

Technicians can verify the accuracy and reliability of their engine diagnostics through precise performance data provided by dynamometers. Directly measuring an engine's power output, dynamometers give technicians a precise understanding of an engine's capabilities, enabling them to identify issues that may not be apparent during regular testing.

Dynamometers simulate real-world operating conditions, replicating exact loads and stresses an engine would experience in actual use, thus guaranteeing that diagnostic results are relevant and reliable.

This allows technicians to pinpoint the root cause of a problem, reducing repair time and costs, and improving total customer satisfaction. Technicians can test an engine's performance under different loads and conditions, such as different speeds, torques, and temperatures, to gather thorough data.

This precise data enables fine-tuning of engine performance, optimisation of fuel efficiency, and guarantees compliance with emissions regulations during emissions tests. Leveraging accurate performance data, technicians can make informed decisions, ensuring that engines are running at their best.

Every instant counts in engine diagnostics, and real-time engine analysis with dynamometers provides the instantaneous feedback technicians need to identify issues and make prompt adjustments.

This capability enables technicians to diagnose engine problems with unparalleled speed and accuracy, reducing downtime.

The benefits of real-time engine analysis with dynamometers are numerous:

Precise load control is a critical component of engine diagnostics, and dynamometers excel in this area, providing technicians with the ability to simulate real-world operating conditions with uncanny accuracy.

Advanced load cells and absorption units work in tandem to apply a precise amount of brake load to the engine, replicating multiple driving scenarios, such as city traffic or highway cruising.

This allows technicians to test an engine's performance under different loads and conditions. Regenerative power electronics further augment the precision of dynamometer tests, enabling accurate measurement of an engine's power output and torque.

With precise load control, technicians can identify issues that may not be apparent during regular testing, such as low-end torque or high-RPM power output.

This enables technicians to pinpoint the root cause of a complaint, optimising engine performance and ensuring the engine produces the maximum amount of power and torque possible.

Identifying issues with precision testing is a pivotal step in diagnosing and resolving complex engine problems, and dynamometers play a fundamental role in this process.

Dynamometers simulate real-world operating conditions, enabling technicians to identify issues that may not be apparent during regular testing and pinpoint the root cause of a complaint with precision.

Dynamometers provide detailed data and insights for accurate diagnosis through replicating diverse driving scenarios and environments, testing engine performance under different loads and conditions.

This helps identify issues such as faulty fuel injectors, clogged air filters, and ignition system problems, which can be difficult to diagnose using traditional testing methods.

Issues that may only occur under certain conditions, such as when the engine is under heavy load or at high RPM, can also be identified.

Additionally, problems that may not be related to the engine itself, such as transmission or drivetrain problems, which can also affect engine performance, can be detected.

Emissions test failures due to road load, electronic controls, acceleration, and deceleration issues can also be pinpointed through dynamometer testing.

In-house dynamometer testing provides a controlled test environment, allowing for precise quality control and expediency, while eliminating reliance on external facilities.

This, in turn, leads to significant cost savings by reducing warranty claims and returns for service after rebuild or repair. By bringing testing in-house, businesses can optimize their testing processes, minimize costs, and ultimately deliver high-quality products to their customers.

In a controlled test environment, technicians can guarantee accurate and reliable test results, unhindered by external influences.

This is made possible through in-house dynamometer testing, which enables precise regulation of temperature, pressure, and other parameters that impact emissions and engine performance.

Conducting precise and reliable testing in a controlled environment yields significant financial benefits.

In-house dynamometer testing reduces testing costs, resulting in substantial savings for manufacturers and repair shops.

Dynamometer ownership proves to be a cost-effective investment, paying for itself in a relatively short period, typically within 1-2 years, depending on the frequency and type of testing.

A dynamometer can be a game-changer for businesses that rely heavily on engine diagnostics and testing, providing a competitive edge in terms of quality, expediency, and cost.

Having in-house dynamometers allows businesses to take full control of their testing processes, eliminating reliance on external facilities and ensuring consistent results.

Full control and expediency are achieved through in-house dynamometers, enabling businesses to test engines at their own pace, thus reducing wait times and allowing for faster turnaround of products and services.

In-house dyno testing leads to increased customer satisfaction as it reduces warranty or return for service after a rebuild or repair, resulting in customer loyalty.

Dyno ownership can generate revenue for the business, making it a valuable investment for companies that rely heavily on engine diagnostics and testing.

Confidence and market share can be instilled in customers through in-house dyno testing, as it ensures they receive the best possible product, leading to increased sales and market share.

As manufacturers face increasingly stringent emissions regulations, accurate and reproducible testing becomes essential for compliance.

Engine dynamometers play a pivotal role in emissions certification, providing precise control over engine operating conditions and allowing for the evaluation of engine performance and emissions under different temperatures, humidity, and other environmental conditions.

Transient test facilities, which include engine dynamometers, simulate real-world driving scenarios, enabling manufacturers to test engine performance and emissions under diverse load conditions.

This guarantees compliance with regulatory standards such as EPA and Euro emissions standards for light-duty or heavy-duty automotive engines.

Engine dynamometer testing is a key component of the emissions test process, providing accurate and reproducible results that help manufacturers optimise engine performance and reduce emissions.

Manufacturers can confidently guarantee their combustion engines meet the necessary standards, paving the way for a cleaner and more sustainable future, through leveraging dynamometers in emissions certification.

Simulating real-world driving scenarios is crucial for evaluating an engine's performance and emissions characteristics.

Transient testing on a dynamometer enables the replication of diverse load and speed conditions, such as city traffic, highway cruising, and mountainous terrain.

Transient testing provides a more realistic representation of an engine's performance and emissions than traditional steady-state testing methods.

This is achieved by applying specific load profiles to an engine, mimicking the resistive forces encountered in real-world driving, and measuring power output, torque, and fuel consumption under these conditions.

Some key benefits of transient testing are:

Dynos have become an indispensable tool for optimising engine performance, allowing technicians to precision-tune engines for maximum power and efficiency.

Accurately measuring an engine's horsepower and torque output, dynos help technicians identify performance bottlenecks and optimise engine tuning for improved power and efficiency. Simulating real-world driving conditions, dynos enable technicians to diagnose issues that may not be apparent during regular testing, such as low-end torque or high-RPM power delivery.

Dyno testing allows for the assessment of engine performance under multiple loads and conditions, enabling technicians to fine-tune fuel and ignition settings for maximum performance and efficiency.

This precise data acquisition enables technicians to make targeted modifications to access an engine's full potential, identifying areas for improvement such as air leaks, exhaust restrictions, or ignition system weaknesses. In addition, dyno testing facilitates emissions testing, ensuring engines meet regulatory standards while minimising environmental impact.

Providing detailed data and insights, dyno testing enables technicians to make data-driven decisions and optimise engine performance, resulting in improved acceleration, throttle response, and total driving experience.

How Dynamometers Augment Engine Diagnostics and Testing

Dynamometer Fundamentals Explained

At Hyper Power, we understand that a dynamometer is a device that measures the torque and rotational speed of an engine, providing accurate data on its performance. By applying a load to the engine, dynamometers simulate real-world scenarios, enabling the measurement of engine power, efficiency, and responsiveness. This data is vital for diagnosing issues, optimising performance, and confirming compliance with emissions regulations. If you have any questions about our Custom Dyno Solutions, please do not hesitate to contact us.

Calculating Engine Performance Accurately

Dynamometers use advanced algorithms to calculate engine performance metrics, such as horsepower, torque, and brake-specific fuel consumption. These calculations provide a precise comprehension of an engine's capabilities, allowing for targeted improvements and repairs. Our team at Hyper Power can assist you with Installation and Setup, Training and Certification, and Technical Support and Maintenance to ensure accurate calculations.

Types of Dynamometers for Testing

There are diverse types of dynamometers, including hydraulic, electric, and eddy current dynamometers. Each type is suited for specific testing applications, such as high-performance engines, diesel engines, or small engines. We can help you determine the best type of dynamometer for your needs. Contact us to learn more about our Dynamometer Testing Services and Accessories and Parts.

Augmenting Engine Diagnostics With Dynos

Dynamometers play a pivotal role in engine diagnostics by providing accurate data on engine performance. This data enables technicians to identify issues, such as faulty fuel injectors or clogged air filters, and develop targeted repair strategies. Our experts at Hyper Power can provide Diagnostics and Performance Analysis to help you identify issues and optimise engine performance.

Identifying Issues With Precision Testing

Precision testing with dynamometers helps identify issues that may not be apparent through traditional testing methods. By simulating real-world scenarios, dynamometers can reveal problems with engine components, such as faulty turbochargers or malfunctioning exhaust systems. Our Rental Services allow you to conduct precision testing without the need for a long-term investment.

Importance of Dyno Ownership for Business

For businesses involved in engine repair, testing, and development, owning a dynamometer can be a valuable investment. It enables them to provide accurate diagnostics, optimise engine performance, and confirm compliance with emissions regulations. At Hyper Power, we offer Software Updates and Upgrades to ensure your dynamometer remains up-to-date and compliant with regulations.

Engine Dynos for Emissions Certification

Dynamometers are vital for emissions certification, as they provide accurate data on engine emissions. This data is used to confirm compliance with regulations and to optimise engine performance for reduced emissions. Our team can assist you with Emissions Certification and Software Updates and Upgrades to ensure compliance.

Transient Testing for Real-World Scenarios

Transient testing with dynamometers simulates real-world scenarios, such as rapid acceleration and deceleration. This testing provides valuable insights into engine performance under dynamic conditions. Contact us to learn more about our Transient Testing capabilities.

Optimising Engine Performance With Dynos

Dynamometers enable the optimisation of engine performance by providing accurate data on engine behaviour. This data is used to fine-tune engine components, such as fuel injectors and ignition systems, for improved performance and efficiency. Our experts at Hyper Power can help you Optimise Engine Performance with our Dynamometer Testing Services.

Conclusion

Dynamometers are vital tools for engine diagnostics and testing, providing accurate data on engine performance and enabling the identification of issues with precision. Their importance extends to businesses, emissions certification, and optimising engine performance. At Hyper Power, we are committed to providing top-notch Custom Dyno Solutions, Installation and Setup, Training and Certification, Technical Support and Maintenance, Software Updates and Upgrades, Diagnostics and Performance Analysis, Rental Services, Dynamometer Testing Services, and Accessories and Parts.

Hydraulic dynos prevent catastrophic field failures—but most heavy industry operators still skip this critical step. Learn why.

Most diesel dyno operators ignore this—and it costs them thousands in failed runs and wasted data.

Stop wasting money on road testing. One dyno investment eliminates comebacks, builds loyalty, and outpaces competitors. Here’s why your workshop needs it.

Diesel turbo lag isn’t inevitable—modern dyno diagnostics reveal the hidden culprits stealing your power. Find out what your engine is hiding.

Fleet operators are throwing money away. Dynos reveal what road tests miss—and how much you’re losing.

Water testing won’t reveal what dyno testing exposes. Learn why engine builders skip this step at their peril.

Tractor performance tests reveal what manufacturers won’t tell you. See how dynamometer data exposes hidden inefficiencies in your equipment.

Diesel engine testing mistakes cost thousands monthly. Learn what separates thriving operations from regulatory nightmares.

No posts found!