How Dynamometers Enhance Engine Diagnostics and Testing

Necessitating precise measurements, dynamometers unlock the secrets of engine performance, but what else can they reveal about engine diagnostics and testing?

The evolution of dynamometers, a vital tool for measuring force, torque, and power, spans over two centuries.

From the 18th century's Graham-Desaguliers dynamometer to Edmé Régnier's portable dynamometer in 1798, the Industrial Revolution catalysed further advancements.

Transmission dynamometers enabled the measurement of mechanical work and power, while planimeters and integrators calculated complex curves and areas.

Dynamometers have been used in diverse applications, including muscle force analysis, sports medicine, and ergonomics.

As technology continues to advance, the story of dynamometer evolution is far from over, with modern innovations waiting to be investigated.

The continued development of dynamometers is set to have a profound impact on a wide range of industries and applications, shaping the future of force, torque, and power measurement.

During the 18th century, the concept of dynamometers began to take shape, with significant advancements unfolding during the Industrial Revolution.

The idea of measuring force and muscle strength had been around for some time, but it wasn't until the late 1700s that the initial practical dynamometers were developed.

In 1763, the Graham-Desaguliers dynamometer was created in London to measure human muscular force, marking one of the earliest attempts to quantify strength.

Edmé Régnier's invention in 1798 revolutionised the field of dynamometry.

His portable dynamometer used an oval, closed spring and displayed maximum force, tension, or compression.

Initially used to test the strength of various groups, Régnier's dynamometer later evolved for use in anthropology, medicine, and sport, in addition to mechanical work measurement.

The Régnier dynamometer was designed to be simple, portable, and precise, capable of testing the strength of a single finger, hand, limb, or the whole body.

This innovation paved the way for further advancements in measuring human muscle strength and force.

Marked by a surge in technological innovation, the Industrial Revolution catalysed significant advancements in dynamometer development, as the imperative for precise measurement of mechanical power became paramount for industrial efficacy and innovation.

Inventors such as Regnier, Morin, and Hirn made substantial contributions to dynamometer technology, introducing innovations like the oval-spring design, plano-parabolic springs, and torsion-based torque measurement.

Transmission dynamometers enabled the measurement of mechanical work and power in industrial machinery, leading to increased efficacy and productivity in manufacturing.

The development of planimeters and integrators enabled the calculation of complex curves and areas, further advancing the field of mechanical engineering and physics.

Dynamometers had become crucial tools in diverse industries, including textiles, mining, and transportation, playing a pivotal role in shaping the modern industrial landscape.

As testing and measurement capabilities improved, industries were able to optimise their operations, leading to significant economic growth and development.

The concept of dynamometry emerged in the 18th century, marked by the development of the Graham-Desaguliers dynamometer in 1763, which measured human muscular force.

This early innovation paved the way for further breakthroughs, including Edme Regnier's invention of the inaugural practical, portable dynamometer in 1798.

These pioneering achievements laid the groundwork for subsequent advancements that would unfold during the Industrial Revolution.

The concept of dynamometers emerged in the 18th century, marking a significant milestone in precision measurement.

During the Industrial Revolution, substantial progress was made, initiating a new era in measuring strength and force.

Edme Regnier designed the pioneering Regnier dynamometer in 1798, a portable device capable of measuring the strength of men, traction force of animals, and resistance to traction of carts.

This innovative device utilised an oval, closed spring and displayed maximum force, tension, or compression, featuring two scales for compression and tension forces, and a pointer registering the maximum force.

The Regnier dynamometer was not only adaptable but also easy to use, making it a crucial tool for multiple applications.

Its publication in the Journal de l'École polytechnique in 1798 paved the way for further developments in the field of dynamometers.

As the pioneering portable and practical device, the Regnier dynamometer set the stage for future innovations, enabling precise measurement of force and strength in multiple domains.

As the Industrial Revolution gathered pace, innovators refined and expanded upon Regnier's pioneering work, propelling dynamometer development into a new era of sophistication.

The 18th century witnessed significant advancements in dynamometer technology, driven by the need for precise measurement of torque and rotational speed.

Notable among these innovations was the introduction of the load cell, which enabled accurate measurement of forces and weights.

British engineer William Froude's invention of the water brake dynamometer revolutionised the field, providing a reliable means of measuring torque.

This breakthrough led to the development of the hydraulic dynamometer, further expanding dynamometer capabilities.

These advancements collectively enhanced dynamometer precision and reliability, making them indispensable tools in diverse industries.

As the century unfolded, dynamometers continued to evolve, laying the groundwork for even more sophisticated designs and applications.

In response to the growing demand for precise mechanical power measurement, innovators of the Industrial Revolution era rose to the challenge, yielding a flurry of early dynamometer innovations and breakthroughs.

This period saw significant advancements in dynamometer technology, driven by the need for accurate measurement of mechanical power in industrial machinery.

Some notable developments during this time include Edme Rgnier's invention of the initial practical, portable dynamometer, capable of measuring force, torque, and power output.

Dynamometers evolved in two directions: anthropology, medicine, and sport, and mechanical work measurement.

Transmission dynamometers were developed, which measured mechanical work and were used to measure the work done and delivered power in agricultural and industrial machinery.

Innovations such as Morin's plano-parabolic spring and the Disk-and-Wheel totalizer enabled more accurate and efficient measurement of mechanical power.

The creation of smaller, more portable dynamometers, such as Mathieu's compression-only version, made mechanical power measurement more accessible.

In the sphere of mechanical and anthropological applications, dynamometers have been instrumental in measuring human strength, providing valuable insights into muscle function and performance.

Muscle force analysis, a key aspect of this field, relies heavily on dynamometers to quantify muscle output and identify patterns of movement.

Measuring human strength has long been a pursuit of both mechanical and anthropological interest, with early innovators laying the groundwork for future dynamometer developments.

The Graham-Desaguliers dynamometer, developed in 1763, was used to measure human muscular force, paving the way for future innovations. Edme Rgnier's dynamometer, invented in 1798, was the inaugural practical and portable device to measure human strength, used by ethnologists to test the strength of indigenous peoples.

Dynamometers have been used in diverse applications to measure human strength, including measuring grip strength and muscular force in different muscle groups, testing human strength in strongmen championships, measuring traction force of animals and resistance to traction of carts, medical applications to test human muscle strength in different contexts, and compression-only measurements in medical contexts.

These early innovations have led to the development of more sophisticated dynamometers, enabling precise measurements of human strength in diverse contexts.

Muscle Force Analysis (Mechanical and Anthropological Applications)

Three key aspects of muscle force analysis – mechanical, anthropological, and biomechanical – have emerged as pivotal components in comprehension of human strength and its applications.

In the context of mechanical applications, muscle force analysis is indispensable in designing devices that interact with the human body, such as grip strength measurement tools, which enable the measurement of the force exerted by an individual's grip, providing valuable insights into muscle function and general strength.

Anthropological applications of muscle force analysis involve the study of human evolution, where researchers use dynamometers to measure the power generated by muscles in different species, helping grasp the adaptability of humans to their environment and how muscle strength has evolved over time.

Biomechanical applications focus on the internal mechanisms of human movement, where muscle force analysis is pivotal in grasping the torque generated by muscles to produce movement, which is indispensable in fields such as sports medicine, rehabilitation, and ergonomics, where the optimization of human movement is critical.

During the late 19th and early 20th centuries, substantial breakthroughs in dynamometer technology paved the way for the development of modern dynamometers.

The evolution of dynamometers from absorption dynamometers to electrical dynamometers enabled the measurement of power in electrical systems, leading to the creation of regenerative dynamometers that could feed AC power back into the commercial electrical power grid.

Modern dynamometers utilise digital control systems and advanced sensors to provide real-time data and accurate measurements.

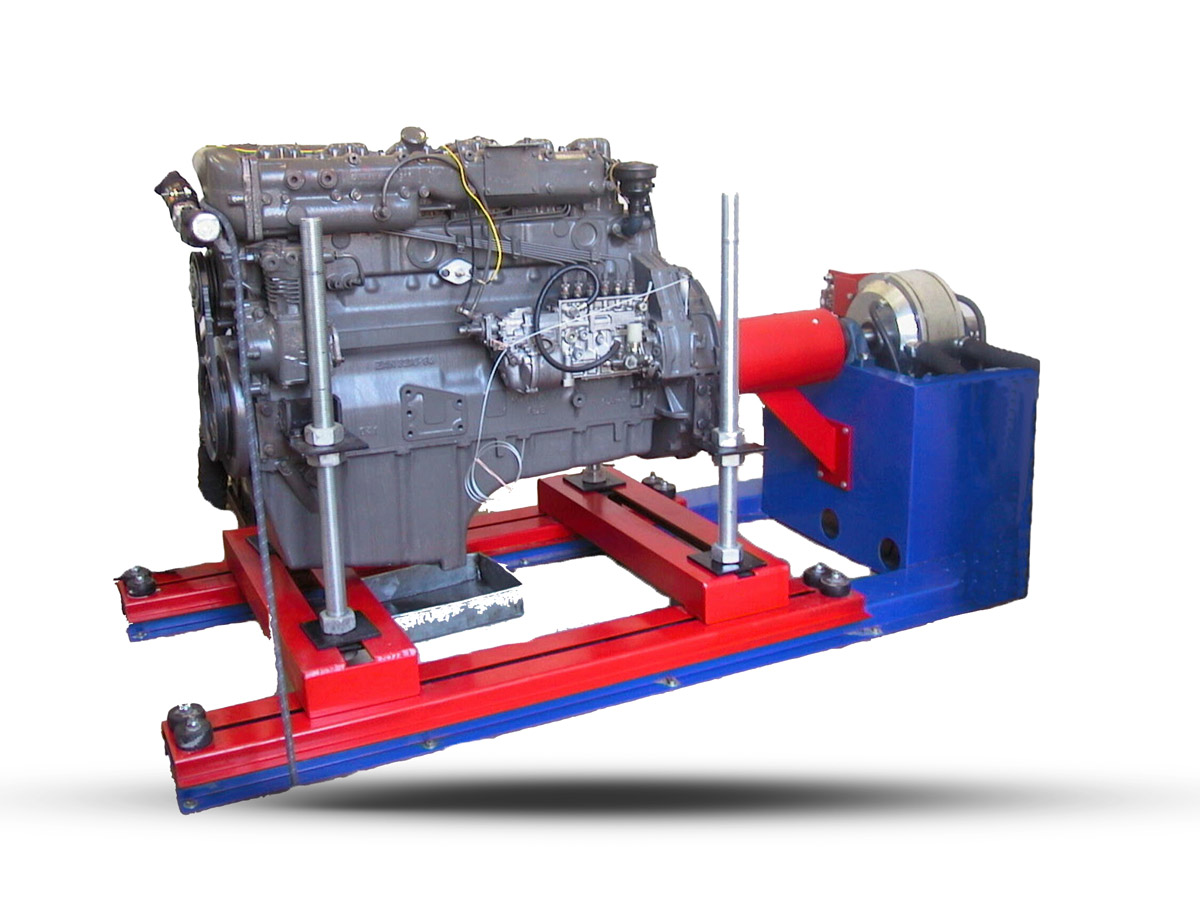

They are employed in diverse industries such as automotive, aerospace, and manufacturing.

Key features of modern dynamometers include the use of electrical signal processing to measure torque and power, data acquisition systems that enable real-time monitoring and analysis, advanced control systems that guarantee precise control of the testing process, integration with IoT connectivity that enables remote monitoring and data analysis, and advanced sensors that provide accurate and reliable measurements.

These advancements have dramatically increased the efficiency and accuracy of modern dynamometers, making them a vital tool in diverse industries.

Several key advancements in technology and materials have played a pivotal role in shaping the modern dynamometer.

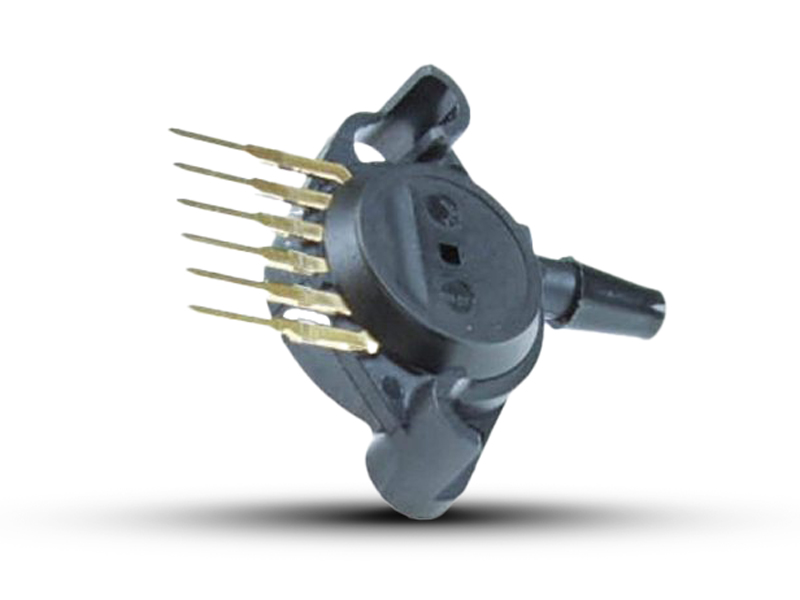

The introduction of strain gauges in the 1930s significantly improved accuracy and sensitivity.

The integration of digital technology in the 1980s enabled the creation of more precise and efficient dynamometers, capable of real-time data acquisition and analysis.

To meet the high power and high-torque application requirements, dynamometers need advanced materials that can withstand such demands, resulting in the development of lighter, stronger, and more durable dynamometers using materials like carbon fibre and nanomaterials.

Sensor technology improvements, such as the development of piezoelectric sensors, have increased the precision and accuracy of dynamometer measurements.

These advancements have enabled dynamometers to operate in a wider range of applications, from low-torque to high-power applications.

The incorporation of artificial intelligence and machine learning algorithms has further augmented the capabilities of modern dynamometers, enabling predictive maintenance, real-time fault detection, and optimised performance monitoring.

These advancements have transformed the dynamometer industry, enabling the creation of high-performance, reliable, and efficient testing and measurement tools.

The modern era of dynamometers has witnessed a significant leap forward in relation to technological advancements and innovative designs.

This progress has enabled the development of advanced technologies such as eddy current, hydraulic, and AC motor dynamometers, which offer improved accuracy and versatility.

Dynamometers designed with electric motor technology have increased power outputs and efficiency.

The integration of digital systems and data analysis software has enabled real-time monitoring and precise measurement of performance parameters.

Compact, portable devices have resulted from miniaturization, suitable for a wide range of applications.

Future directions in dynamometer technology include the development of sustainable, eco-friendly designs.

The incorporation of artificial intelligence and machine learning algorithms is expected to augment predictive maintenance and optimisation.

As demand for precise measurement and analysis continues to grow, dynamometer technology is poised to evolve further, focusing on improving accuracy, reliability, and cost-effectiveness.

A Comprehensive History of Dynamometer Evolution

Origins of Dynamometers

The concept of dynamometers dates back to ancient civilisations, where primitive devices were used to measure force and power. In ancient Greece, Aristotle described a rudimentary dynamometer consisting of a lever and a spring. This concept was later refined in the 17th century by French physicist Gustave Coriolis, who developed a more sophisticated dynamometer to measure the mechanical advantage of simple machines.

Industrial Revolution Advancements

The Industrial Revolution marked a significant turning point in dynamometer development. As machines became more complex and powerful, the need for accurate measurement of force and power grew. In the 18th century, English engineer James Watt developed a dynamometer to measure the power of steam engines, paving the way for more advanced measurements.

Early Innovations and Breakthroughs

The 19th century saw significant innovations in dynamometer design. French engineer Jean-Victor Poncelet developed a dynamometer that could measure both static and dynamic forces. This breakthrough led to the development of more sophisticated dynamometers, including the first electric dynamometers.

Mechanical and Anthropological Applications

Dynamometers soon found applications beyond industrial settings. In the early 20th century, dynamometers were used to measure human strength and endurance, leading to significant advances in fields such as sports medicine and ergonomics.

Development of Modern Dynamometers

The mid-20th century saw the development of modern dynamometers, characterised by increased accuracy, precision, and versatility. These advancements were driven by advances in materials science, electronics, and computer technology.

Advancements in Technology and Materials

The latter half of the 20th century saw significant advancements in dynamometer technology and materials. The introduction of strain gauges, piezoelectric sensors, and advanced materials such as titanium and advanced ceramics enabled the development of more accurate, durable, and compact dynamometers.

Modern Era and Future Directions

Today, dynamometers are used in a wide range of applications, from aerospace engineering to medical research. Hyper Power, a leading provider of custom dyno solutions, invites you to explore our range of services, including Custom Dyno Solutions, Installation and Setup, Training and Certification, Technical Support and Maintenance, Software Updates and Upgrades, Diagnostics and Performance Analysis, Rental Services, Dynamometer Testing Services, and Accessories and Parts. If you have any questions about our services, please do not hesitate to contact us.

Conclusion

The evolution of dynamometers reflects a centuries-long quest for precision, accuracy, and innovation. From ancient Greece to modern times, dynamometers have played a crucial role in advancing scientific understanding, industrial development, and human knowledge. As technology continues to evolve, dynamometers will remain a vital tool for measuring and understanding the complex forces that shape our world.

Necessitating precise measurements, dynamometers unlock the secrets of engine performance, but what else can they reveal about engine diagnostics and testing?

Navigating the complexities of torque measurement requires a deep understanding of the underlying principles and mechanisms to ensure accurate results.

Precise control and optimization of engine performance await, but only for those who unlock the secrets of dynamometer-driven data analysis.

Gaining insight into the differences between inertia and brake dynamometers is crucial for ensuring accurate testing results in various industries.

Tapping into the precise measurement capabilities of dynamometers, uncover the secrets to optimizing fuel efficiency and slashing emissions in the automotive industry.

Witness the importance of rigorous safety protocols and best practices in dynamometer testing to avoid catastrophic failures and ensure accurate results.

Harnessing the nuances of precision measurement is crucial to avoiding costly errors in dynamometer testing, but what are the key factors to consider?

Witness the transformative power of dynamometers in unlocking your vehicle’s hidden performance potential, but only if you know how to harness their precision.

Hyper Power, the leading name in dynamometer solutions, offers unparalleled precision and reliability for all your performance testing needs.