How Dynamometers Enhance Engine Diagnostics and Testing

Necessitating precise measurements, dynamometers unlock the secrets of engine performance, but what else can they reveal about engine diagnostics and testing?

Inertia dynamometers designed for motorcycles and lightweight vehicles provide a precise and reliable means of measuring engine performance, enabling users to fine-tune engines and make informed decisions about modifications.

These dynamometers accurately collect data on torque and horsepower in relation to engine RPM, identifying performance differences and areas for improvement.

With features such as zooming in on graph data down to 30 RPM engine increments, users can gain a detailed insight into their engine's performance.

A range of solutions and customisation options are available, tailored to specific testing requirements.

When evaluating an engine's performance, a thorough grasp of its dynamic characteristics is crucial.

Inertia dynos, a type of chassis dynamometer, provide accurate and detailed information about an engine's performance. These dynos utilise a data acquisition system to collect acceleration data in engine RPM increments, allowing for the identification of where acceleration falls off or slows down.

The collected data can be graphically represented, displaying S.A.E. corrected torque and horsepower in relation to engine RPM.

Up to six graph dyno pull overlays can be compared to identify performance differences. Additionally, zooming in on graph data is possible down to 30 RPM engine increments for detailed analysis.

This level of precision enables users to make informed decisions about engine modifications and fine-tuning.

Inertia dynos' advanced features make them a fundamental tool for engine developers, tuners, and enthusiasts seeking to optimise their engine's performance.

Users can tap into the full potential of their engine, achieving improved torque measurement and superior performance.

When fine-tuning engine performance, inertia dynos have proven to be an indispensable tool, and their applications extend to motorcycle and lightweight vehicle testing.

Inertia dynamometers for motorcycles and lightweight vehicles can measure acceleration data in engine RPM increments, such as 50, 75, or 100, to identify where acceleration falls off or slows down. This precise testing enables engineers to optimise engine performance, ensuring maximum power and efficiency.

Several dynamometers are specifically designed for motorcycle and lightweight vehicle testing.

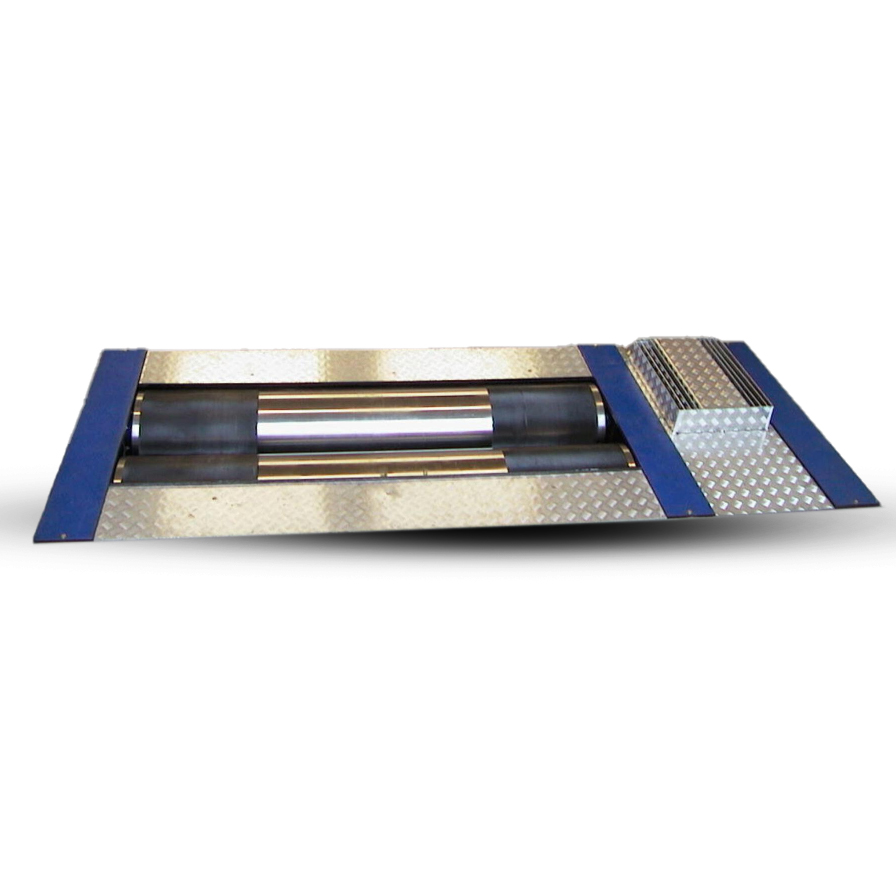

The Dynostar D50i and D50ECB offer high-performance solutions for testing motorcycles and scooters up to 200Hp. The Mustang Dynamometer's MD-SXS/UTV Dyno provides a high-speed, low-profile design with eddy current loading features for precision tuning and diagnostic applications.

The SF-250A Powersport Chassis Dyno is rated for 750+ hp (inertia) and 500+ hp (eddy-current), with features such as a rugged, impact-resistant handheld controller and eddy-current load options.

These dynamometers cater to diverse testing requirements, ensuring accurate and reliable results.

Installed in a dedicated space, an inertia dynamometer necessitates careful consideration of the dyno room and installation to ensure accurate and reliable test results.

The dyno room's dimensions, particularly the inside width of the door or building, must be measured to determine the dyno's width, which can be either 71 cm or 91 cm.

Axle size and bearing quality are critical considerations, with options for 3.18 cm or 3.81 cm stress-proof axles to accommodate different engine sizes and applications.

Table length options, including 91 cm, 122 cm, or custom lengths, must be chosen to fit the engine size and type of motorcycle or lightweight vehicle being tested.

Electric start options add to the table length and provide belt drive capabilities for easier testing and data collection.

Locking pneumatic swivel casters with tubes are vital to provide easy movement and storage.

A low-profile design ensures the dyno fits comfortably in the test room or facility, allowing for efficient testing and data collection.

Careful consideration of these factors verifies accurate and reliable test results from the inertia dynamometer.

Optional features and upgrade options for inertia dynamometers significantly enhance their functionality, providing users with a more comprehensive understanding of engine performance and facilitating more precise tuning.

These refinements enable users to gain a deeper insight into their engine's behaviour, allowing for more effective optimisation.

Air/fuel ratio measurement, for example, is an optional feature that analyses the air/fuel mixture's effect on torque and horsepower. This data is vital for fine-tuning engine performance.

Fuel flow measurement is also available, providing precise data for engine tuning through electronic sensors. An electronic blow-by sensor is another optional upgrade that measures leak down, ring flutter, and compression loss.

Other upgrade options include stub axle ends, which allow for adding an alternative flywheel or chassis dyno table in the future, increasing the dynamometer's versatility.

A one-way sprag clutch is another optional feature that allows the dyno flywheel to coast if the engine locks up, preventing damage to the engine or dyno.

These features demonstrate the adaptability of inertia dynamometers, making them an ideal choice for motorcycle and lightweight vehicle enthusiasts seeking precise engine tuning and analysis.

Selecting the ideal inertia dynamometer for specific engine testing needs requires careful consideration of several key factors.

To guarantee the chosen dyno performs tests accurately, it is vital to determine the minimum and maximum horsepower requirement. The type of motor, whether 2-cycle or 4-cycle, and its RPM range must be taken into account.

Customisation options are available to accommodate individual needs and applications.

The right bearing quality, such as ISO 9001 Chinese bearings or high-quality NTN Japanese bearings, can profoundly impact the dyno's performance. Table length and electric start options can also be customised to fit different engine sizes.

Additionally, features like air/fuel ratio measurement, electronic blow-by sensor, and fuel flow measurement can be added to analyse the air/fuel mixture's effect on torque and horsepower.

A well-designed control system is vital to ensure seamless operation and accurate data collection.

Inertia Dynamometers for Motorcycles and Lightweight Vehicles

Inertia Dyno Features and Applications

Our inertia dynamometers are specifically designed to test motorcycles and lightweight vehicles, providing accurate measurements of torque, power, and speed. These dynos utilise a rotating drum or roller to simulate real-world driving conditions, allowing for precise data collection. As Hyper Power, we understand that inertia dynos are ideal for testing smaller vehicles, as they can accommodate lower power outputs and are more compact than traditional dynamometers.

Motorcycle and Lightweight Vehicle Testing

Our inertia dynamometers are particularly suited for motorcycle and lightweight vehicle testing due to their ability to accurately measure low-torque and high-RPM outputs. This allows for precise analysis of engine performance, gear ratios, and drivetrain components. Additionally, inertia dynos can be used for research and development, endurance testing, and emissions testing. If you have any questions about our Custom Dyno Solutions, please do not hesitate to contact us.

Dyno Room and Installation Considerations

When installing an inertia dynamometer, it is vital to take into account the dyno room's dimensions, ventilation, and electrical infrastructure. A well-designed dyno room should provide adequate space for the dyno and test vehicle, as well as proper ventilation to remove heat and exhaust gases. Furthermore, the electrical infrastructure must be able to support the dyno's power requirements. Our Installation and Setup services can assist with this process.

Optional Features and Upgrade Options

Our inertia dynamometers can be customised with a range of optional features and upgrade options to augment their functionality. These may include advanced data acquisition systems, thermal imaging cameras, and automated test cycles. Upgrades can also be made to the dyno's mechanical components, such as the drum or roller, to accommodate different test vehicle types or to increase testing capacity. If you require any Technical Support and Maintenance, we are here to help.

Purchasing and Customization Guidelines

When purchasing an inertia dynamometer, it is vital to take into account the specific testing requirements of the intended application. Factors such as power output, speed range, and data acquisition requirements should be carefully evaluated. Moreover, the dyno's durability, reliability, and maintenance requirements should be assessed to guarantee optimal performance and longevity. We offer Software Updates and Upgrades to ensure your dyno stays up-to-date.

In summary, our inertia dynamometers provide a precise and efficient means of testing motorcycles and lightweight vehicles, offering a range of features and customisation options to suit specific testing requirements. If you require any Diagnostics and Performance Analysis, Rental Services, Dynamometer Testing Services, or Accessories and Parts, please contact Hyper Power for more information.

Necessitating precise measurements, dynamometers unlock the secrets of engine performance, but what else can they reveal about engine diagnostics and testing?

Navigating the complexities of torque measurement requires a deep understanding of the underlying principles and mechanisms to ensure accurate results.

Precise control and optimization of engine performance await, but only for those who unlock the secrets of dynamometer-driven data analysis.

Gaining insight into the differences between inertia and brake dynamometers is crucial for ensuring accurate testing results in various industries.

Tapping into the precise measurement capabilities of dynamometers, uncover the secrets to optimizing fuel efficiency and slashing emissions in the automotive industry.

Witness the importance of rigorous safety protocols and best practices in dynamometer testing to avoid catastrophic failures and ensure accurate results.

Harnessing the nuances of precision measurement is crucial to avoiding costly errors in dynamometer testing, but what are the key factors to consider?

Witness the transformative power of dynamometers in unlocking your vehicle’s hidden performance potential, but only if you know how to harness their precision.

Hyper Power, the leading name in dynamometer solutions, offers unparalleled precision and reliability for all your performance testing needs.