How Dynamometers Enhance Engine Diagnostics and Testing

Necessitating precise measurements, dynamometers unlock the secrets of engine performance, but what else can they reveal about engine diagnostics and testing?

Dynamometers are essential for enhancing engine performance, diagnosing issues, and increasing equipment efficiency in workshops. They enable accurate measurement of engine parameters, identification of potential problems, and adjustments to enhance performance.

By providing valuable insights into engine efficiency and early issue detection, dynamometers help achieve outstanding performance and ensure optimal power output. Their role in diagnostics is crucial for pinpointing engine problems, while calibration ensures precise readings.

Dynamometers are key in improving machinery design, identifying issues, and upholding high performance standards, contributing to workshop efficiency and safety. Explore the advantages further to maximise workshop potential.

Significance of Dynamometers in Garages

Dynamometers are crucial tools in garages as they enable accurate measurement and enhancement of engine performance parameters. One key area where dynamometers excel is in assessing hand grip strength. By measuring the force applied by the hand on the dynamometer, mechanics can evaluate the engine's efficiency in generating power. This information is valuable for fine-tuning engines to operate at their best, ensuring optimal power utilization.

The evaluation of hand grip strength also plays a vital role in identifying potential engine issues. A weak hand grip reading could signal underlying problems in the engine components that require attention. Through dynamometer testing for hand grip strength, garage professionals can pinpoint areas needing improvement and make necessary adjustments to enhance overall engine performance. This precise approach not only maximizes power output but also contributes to improved efficiency and longevity of the engine.

Therefore, incorporating hand grip measurements through dynamometer assessments is a crucial step in achieving top-notch performance in garages.

Advantages of Dynamometer Testing

The comprehensive evaluation provided by dynamometer testing gives mechanics valuable insights into enhancing engine performance and detecting issues early on. By using a hand dynamometer, professionals can precisely measure torque, RPM, and horsepower to assess engine efficiency thoroughly. This information is crucial for adjusting components like the intake manifold, ignition timing, and carburettor size to improve performance.

Furthermore, dyno testing allows for the early identification of potential engine problems, enabling prompt intervention and preventative maintenance. Monitoring exhaust gas temperature in testing helps optimise fuel distribution and prevents expensive engine damage. The performance report generated from dyno testing acts as a valuable tool for making data-informed decisions, aiding in future enhancements and trend analysis in the workshop.

In essence, dynamometer testing benefits go beyond just evaluating performance; it provides workshop professionals with a strategic advantage in enhancing engine efficiency and longevity.

Enhancing Vehicle Performance with Dynamometers

Optimising your vehicle's performance by strategically utilising dynamometer testing is crucial for maximising engine efficiency and output. Dynamometers are essential for measuring grip, torque, horsepower, and engine efficiency, providing valuable insights into your vehicle's capabilities. By adjusting engine components like intake manifold selection and ignition timing based on dyno test results, you can achieve peak performance levels. These tests also help in early identification of potential issues, enabling timely adjustments to be made.

Dynamometers offer precise data on power output and engine behaviour, ensuring that your vehicle operates optimally. This accurate evaluation enhances the overall performance of your vehicle, making it more efficient and powerful on the road. By integrating dynamometers into your workshop, you can effectively enhance your vehicle's performance, giving you a competitive edge in everyday driving and racing scenarios.

For instance, using a high-quality dynamometer like the Dynojet 224xLC can provide accurate readings for fine-tuning your vehicle's performance. This specific dynamometer offers advanced features that can help you optimise your engine components effectively.

Role of Dynamometers in Diagnostics

When identifying vehicle issues, precise measurements of torque, RPM, and horsepower provided by dynamometers are essential for efficiently pinpointing and resolving engine problems. Dynamometers act as crucial tools in the automotive world, aiding mechanics in uncovering the mysteries hidden within the engine. By analysing the data from dynamometer tests, technicians can identify issues related to power output, fuel efficiency, and overall engine performance. These tools are akin to the stethoscopes used by doctors, enabling them to listen to the heartbeat of your vehicle and diagnose any irregularities. Without dynamometers, diagnosing engine problems would be a challenging and time-consuming task, akin to solving a puzzle blindfolded. So, remember that dynamometers are invaluable aids in unravelling the engine's secrets and ensuring your vehicle runs smoothly.

Importance of Dynamometer Data Analysis

The analysis of data obtained from dynamometer tests is crucial for understanding the performance of a vehicle's engine. By examining torque, RPM, and horsepower measurements, technicians can identify any anomalies or inefficiencies in the engine's operation. For example, if a dynamometer test reveals a significant drop in horsepower at high RPMs, this could indicate issues with the engine's fuel delivery system or ignition timing. Such insights allow mechanics to make targeted repairs and adjustments, ultimately improving the overall performance and efficiency of the vehicle.

Utilising Dynamometers for Performance Tuning

In addition to diagnosing issues, dynamometers are also valuable tools for performance tuning and optimisation. Automotive enthusiasts and racing teams often use dynamometer testing to fine-tune engine parameters and maximise power output. By conducting multiple dyno runs and adjusting variables such as air-fuel ratio and ignition timing, enthusiasts can enhance the performance of their vehicles for track days or competitions. For example, by analysing dyno data and making precise adjustments, a racing team can achieve optimal power delivery and acceleration, giving them a competitive edge on the racetrack.

Enhancing Engine Efficiency with Dynamometer Testing

Dynamometer testing is instrumental in improving engine efficiency and fuel economy. By measuring and analysing torque and horsepower data, technicians can identify areas where the engine may be operating inefficiently or consuming more fuel than necessary. For instance, a dynamometer test showing a dip in torque at low RPMs could indicate issues with the engine's air intake system or exhaust components. Addressing these inefficiencies through targeted repairs or upgrades can result in improved fuel economy and overall performance, saving the vehicle owner money on fuel costs in the long run.

Optimising Equipment Functionality with Dynamometers

Utilising dynamometers in workshops is crucial for maximising the functionality and efficiency of equipment by accurately measuring force, torque, and power output. When it comes to enhancing equipment functionality, dynamometers act as a precise guide, providing insights into the performance characteristics of various tools. This enables the fine-tuning of engines, early detection of inefficiencies, and a boost in productivity levels.

| Advantages of Dynamometers | Description |

|---|---|

| Evaluate Efficiency | Assess the performance of machinery to achieve superior outcomes. |

| Identify Problems | Pinpoint potential issues for timely resolution. |

| Enhance Design | Improve equipment efficiency through thorough data analysis. |

| Optimise Performance | Adjust engine components for optimal operation. |

| Boost Productivity | Ensure machines operate at their highest capacity. |

Adjusting your dynamometer is like fine-tuning a musical instrument before a performance. It guarantees that every note played is accurate and vibrates perfectly.

Just as a musician relies on a well-tuned instrument for a flawless melody, a properly calibrated dynamometer is essential for precise measurements and optimal equipment performance.

Importance of Dynamometer Calibration

Ensuring precise force and torque measurements, dynamometer calibration is a crucial practice that forms the foundation of reliable and consistent results in workshop environments. Calibration is akin to tuning an instrument before a performance; it guarantees that the dynamometer produces accurate readings every time. By rectifying any deviations or errors in the readings, calibration ensures that your dynamometer remains accurate and reliable, ready to provide trustworthy data for various testing and research purposes. Just as a chef adjusts seasoning to perfect a dish, regular calibration is essential for maintaining the accuracy and performance of your dynamometer. Therefore, a well-calibrated dynamometer is an invaluable tool in your workshop, always ensuring that your measurements are precise.

The significance of Dynamometer Calibration

Calibrating your dynamometer regularly is essential for maintaining accurate measurements and reliable performance. For example, products like the Mecmesin MultiTest-i Force Testing System come with built-in calibration features to simplify the process and ensure optimal accuracy. By investing time in calibration, you can enhance the credibility of your test results and trust in the data obtained from your dynamometer. So, consider calibration as a fundamental step in ensuring the quality and accuracy of your workshop measurements.

Benefits of Dynamometer Calibration

Calibration of your dynamometer not only guarantees accurate measurements but also enhances the longevity and efficiency of the equipment. For instance, using calibration services from reputable companies like SensorData Technologies can help you identify and rectify any issues in your dynamometer, ensuring its optimal performance over time. By calibrating your dynamometer regularly, you can prolong its lifespan, maintain its accuracy, and improve the overall quality of your testing processes. Therefore, make dynamometer calibration a priority to reap the benefits of precise and reliable measurements in your workshop.

The precise calibration of a dynamometer is essential to ensure the accuracy and precision of force, torque, and power measurements in workshop environments. Calibration of a dynamometer is crucial as it guarantees that the measurements obtained are dependable and free from errors, maintaining consistency and repeatability in readings over time. This accuracy plays a vital role in fine-tuning performance and diagnosing issues in engines and machinery. Through regular calibration, workshops can uphold their standards and credibility, producing reliable testing results. Consistent calibration upkeep is vital to sustain the dynamometer's ability to provide accurate measurements, supporting the efficiency of workshop processes. Ultimately, dynamometer calibration is fundamental for obtaining dependable and precise performance data in workshop settings.

The Significance of Dynamometer Calibration

Proper calibration of a dynamometer is crucial for ensuring the accuracy of performance measurements. For instance, when calibrating a Dynojet dynamometer used for testing motorcycle engines, the accuracy of the power output readings directly impacts the adjustments made to the engine for optimal performance.

Maintaining calibration precision is key to achieving reliable results in workshop operations. In the case of a SuperFlow dynamometer utilised for assessing car engine performance, accurate torque measurements are essential for diagnosing engine issues and enhancing overall efficiency.

Regular calibration checks are necessary to uphold the integrity of workshop testing processes. For example, in a workshop using a Mustang dynamometer for tuning high-performance vehicles, consistent calibration ensures that the power measurements are trustworthy and assist in enhancing vehicle performance.

By prioritising dynamometer calibration, workshop operators can ensure the accuracy and reliability of their performance data. For instance, in a facility utilising a Dynapack dynamometer for tuning race cars, precise power and torque measurements aid in achieving optimal engine performance and reliability.

Optimising performance through precise dynamometer calibration is essential for achieving maximum efficiency in workshop operations. When it comes to maximizing engine power, accuracy is crucial.

Picture calibrating a hydraulic grip; you aim for just the right tension, not too loose or too tight. Similarly, dynamometer calibration ensures your engine is delivering power optimally, like finding the perfect grip on a tool.

Data Analysis from Dynamometer Testing

Engine performance testing offers valuable insights into metrics like torque, horsepower, and volumetric efficiency, enabling a comprehensive assessment for improvement. Dynamometers are not limited to engines; they can also measure human strength, such as Hand Grip Dynamometers for evaluating grip strength. This data helps individuals understand their hand strength levels, guiding their training and progress effectively.

In the context of engines, dynamometer data serves as a crucial tool for uncovering the inner workings of your engine's performance. By examining factors like cylinder temperatures and airflow, early detection of issues becomes possible, allowing for prompt adjustments to optimise engine operation. Each testing session accumulates valuable data that informs decision-making for enhancing overall engine performance.

Utilising dynamometers provides a wealth of insights for both hand strength assessment and engine performance enhancement. These tools not only quantify strength but also reveal areas for improvement and growth. For example, products like the 'Jamar Hydraulic Hand Dynamometer' offer precise measurements that can be used to tailor strength training programmes effectively. Similarly, dynamometer data for engines acts as a key to unlocking opportunities for fine-tuning and boosting performance.

Dynamometers for Performance Tuning

Enhancing engine performance through precise measurement and analysis is vital for optimising vehicle efficiency. Dynamometers play a crucial role in this process, particularly in performance tuning. Dyno testing enables mechanics and enthusiasts to delve deep into the engine's core, uncovering its hidden potential and adjusting various components to maximise power output efficiently.

To offer a clearer insight, here's a simple breakdown:

| Dyno Testing Advantages | Description |

|---|---|

| Optimise Engine Variables | Fine-tune intake manifold, ignition timing, cam grind, carburettor, and jetting |

| Assess Engine Performance | Pinpoint issues, tweak components for optimal efficiency |

| Monitor Exhaust Gas Temperature | Enhance fuel distribution, prevent engine damage, sustain efficient combustion |

Through dyno testing, you're not just pushing your engine to its limits; you're guaranteeing it functions at its peak performance. Therefore, next time you're in the garage, remember that dyno testing is your gateway to unlocking the true potential of your vehicle.

Versatility of Dynamometers in Workshops

In workshop environments, dynamometers offer a wide range of capabilities for measuring torque, force, and power output across various tools and equipment. These adaptable instruments are extensively used to evaluate the performance and efficiency of engines, motors, and different mechanical systems. By providing precise measurements, dynamometers play a crucial role in enhancing machinery design, pinpointing issues, and ensuring optimal operational efficiency in workshops.

The versatility of dynamometers enables the testing of a diverse range of engines, motors, and components to ensure they meet necessary specifications and standards. This flexibility not only enhances safety but also minimises downtime, ultimately boosting overall productivity by providing valuable performance data. Workshop proprietors and technicians depend on dynamometers to fine-tune equipment, pinpoint areas for enhancement, and confirm that each tool functions at its best capacity.

Embracing the versatility of dynamometers in workshops is essential for upholding high performance and safety standards while maximising operational output.

In summary, dynamometers are essential tools in workshops for testing, diagnosing, and optimizing vehicle performance. They play a crucial role in ensuring equipment functionality and providing valuable data insights.

By using dynamometers, technicians can enhance vehicle performance, conduct diagnostics, and calibrate equipment effectively. The versatility and benefits of dynamometers make them vital in any workshop setting.

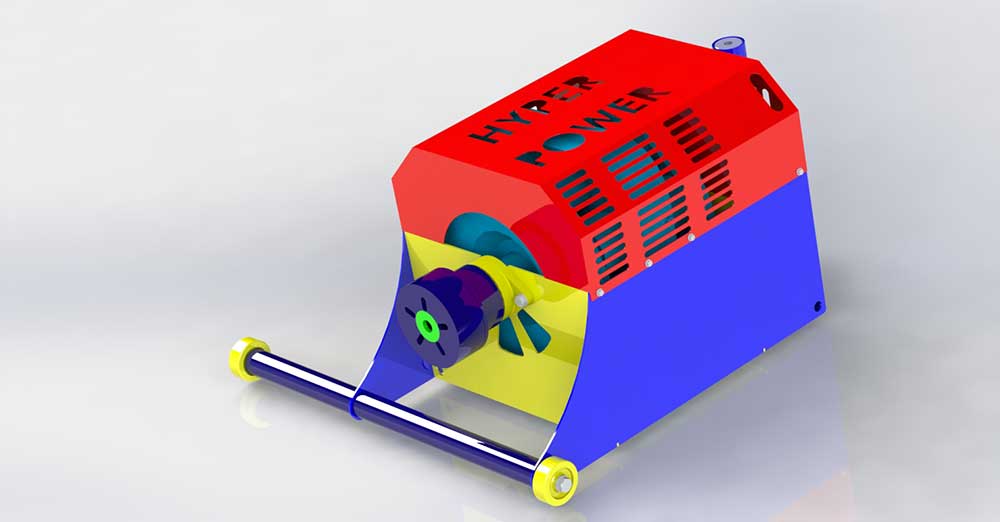

Hyper Dyno is here to help you explore more about Dynamometer Products, Custom Solutions, Installation Setup, Training and Certification, Technical Support and Maintenance, Software Updates, Rental Services, Dynamometer Testing Services, and Accessories and Parts.

If you have any questions, feel free to contact us for assistance.

Necessitating precise measurements, dynamometers unlock the secrets of engine performance, but what else can they reveal about engine diagnostics and testing?

Navigating the complexities of torque measurement requires a deep understanding of the underlying principles and mechanisms to ensure accurate results.

Precise control and optimization of engine performance await, but only for those who unlock the secrets of dynamometer-driven data analysis.

Gaining insight into the differences between inertia and brake dynamometers is crucial for ensuring accurate testing results in various industries.

Tapping into the precise measurement capabilities of dynamometers, uncover the secrets to optimizing fuel efficiency and slashing emissions in the automotive industry.

Witness the importance of rigorous safety protocols and best practices in dynamometer testing to avoid catastrophic failures and ensure accurate results.

Harnessing the nuances of precision measurement is crucial to avoiding costly errors in dynamometer testing, but what are the key factors to consider?

Witness the transformative power of dynamometers in unlocking your vehicle’s hidden performance potential, but only if you know how to harness their precision.

Hyper Power, the leading name in dynamometer solutions, offers unparalleled precision and reliability for all your performance testing needs.