Hydraulic Dynos: Applications in Heavy Industry Jobs

Hydraulic dynos prevent catastrophic field failures—but most heavy industry operators still skip this critical step. Learn why.

Inertia dynamometers have revolutionised high-speed testing, providing precise and reliable measurements of engine performance.

This enables engineers to optimise power and torque with unprecedented efficiency, accurately evaluating the acceleration of a known mass load to simulate dynamic driving conditions.

Unlike traditional dynamometers, inertia dynos detect even small performance increments, facilitating data-driven decisions and significant cost savings.

As the demands of high-speed testing continue to evolve, inertia dynamometers are poised to play an increasingly essential role in releasing the full potential of engine performance, helping to fine-tune engines for improved performance and fuel efficiency.

High-speed testing poses a significant challenge in accurately measuring engine performance, as modern engines' high-power output often pushes traditional dynamometers to their limits, leading to inaccurate results.

This is particularly true when testing high-performance engines, which require precise and repeatable measurements to optimise their performance. Traditional dynamometers struggle to control these high-power engines, resulting in inaccurate torque and power measurements.

Accurate measurement of engine performance under diverse load conditions is a daunting task in high-speed testing.

Modern engines' high-power output demands precise load control, which traditional dynamometers find difficult to achieve. In contrast, inertia dynamometers offer a solution to these challenges, providing precise torque calculation and repeatable results, making them an ideal choice for high-speed testing applications.

Accurate measurement of engine performance relies on the ability to control and measure the load applied to the engine.

An inertia dynamometer measures power output by accurately evaluating the acceleration of a known mass load, providing precise and reliable data on engine performance. This is achieved through coupling the engine to a known amount of inertia via a clutch system, accelerating the inertia mass, and measuring the acceleration rate to calculate the torque value.

The inertia dynamometer initiates its testing range above idle position, progressing to maximum RPM, offering a more realistic simulation of dynamic driving conditions for precise power measurement.

The combination of a clutch and gearbox in an inertia dynamometer enables precise torque calculation and measurement of performance at different RPM points. With an inertia dynamometer, engine performance can be measured within 0.1% of engine performance, allowing for repeatability and detection of minor increments in power output.

This precise measurement is made possible through the load cell, which accurately measures the moment of inertia and rotational speed in revolutions, ultimately providing the torque and rotational speed data necessary for accurate engine performance evaluation.

Measuring power with an inertia dynamometer is a precise and reliable method for evaluating engine performance.

It accurately evaluates the acceleration of a known mass load, providing precise and reliable data on torque and power output. This is achieved through testing that initiates above idle position and progresses to peak RPM, offering a more realistic simulation of dynamic driving conditions for precise power measurement.

The acceleration rate of the inertia mass is measured to calculate torque, and the gearbox reduces the speed of the spinning inertia mass, enabling measurement of performance at different RPM points.

This allows for precise power measurement and detection of even the smallest improvements in performance. Inertia dynamometers provide repeatability that detects 1-2 horsepower increments, enabling improvement in areas previously unknown.

With an accuracy of 0.1% of engine performance, inertia dynos are ideal for high-speed testing and optimisation, providing engineers with the data they need to fine-tune their engines and optimise performance.

Optimising engine performance demands precision, and inertia dynamometers deliver it through high-speed testing that yields unparalleled efficiency.

Accurately measuring power output and torque within 0.1% of engine performance, inertia dynamometers enable precise optimisation, especially at high RPM ranges. This level of precision allows for the detection of even the smallest increments in engine performance, such as 1-2 horsepower, ensuring optimal performance.

The benefits of high-speed testing efficiency are multifaceted.

Inertia dynamometers accelerate faster lap times on the racetrack, providing accurate data for engine performance optimisation, leading to improved aggregate performance.

They enable improvement of engine performance in previously unknown areas, leading to refined overall engine behaviour.

Precise and reliable measurements of engine performance reduce the time and resources required for high-speed testing, resulting in significant cost savings.

On the whole, the benefits of high-speed testing efficiency with inertia dynamometers are undeniable, paving the way for optimal engine performance and reduced testing costs.

Inertia dynamometers offer unparalleled benefits in high-speed testing efficiency, making it essential to examine their advantages over other types of dynamometers.

These devices stand out due to their exceptional accuracy, measuring performance within 0.1% of engine performance. This precise measurement enables the detection of even the smallest performance increments, making them ideal for fine-tuning engine performance.

In contrast to traditional dynamometers, inertia dynos accurately measure torque and power output, facilitating faster lap times on the racetrack and enhancing insight into engine behaviour under diverse load conditions.

The repeatability of inertia dynos allows for 1-2 horsepower increments to be detected, making them a valuable tool for engine performance optimisation.

Inertia dynos provide accurate data, enabling improvement in areas previously unknown, which gives teams a competitive edge in high-speed testing.

In high-performance testing, precision is paramount, and replicating real-world driving conditions is crucial for obtaining accurate and reliable results.

Inertia dynamometers excel in this regard, accurately simulating real-world driving conditions through the evaluation of a known mass load's acceleration. This approach provides precise power measurement and realistic simulation of dynamic driving conditions.

Unlike loading dynamometers, inertia dynos initiate their testing range above idle position and progress to maximum RPM, offering a more realistic simulation of dynamic driving conditions for precise power measurement.

Accurate force measurement through acceleration and mass enables inertia dynamometers to simulate the sensation of acceleration on the road, making them ideal for tasks such as emissions testing and certification.

In replicating actual load conditions, inertia dynamometers offer insights into engine performance in real-world driving scenarios, enabling accurate and reliable results.

Inertia dynamometers provide in-depth knowledge of engine performance in real-world conditions through precise measurement and realistic simulation.

Inertia dynamometers play a vital role in performance optimization by facilitating real-world simulation testing, precise power measurement, and engine optimization techniques.

These capabilities enable engineers to fine-tune engine performance, discover hidden areas for improvement, and make data-driven decisions.

One of the most significant advantages of inertia dynamometers is their ability to simulate real-world driving conditions, providing a highly accurate representation of an engine's performance in high-speed testing.

This simulation enables engineers to test engines under realistic load conditions, allowing for precise optimisation and improvement.

Inertia dynamometers can accurately measure power output and detect small performance increments, typically 1-2 horsepower, allowing for fine-tuning of engines.

Furthermore, they can initiate testing above idle position and progress to maximum RPM, offering a more realistic simulation of dynamic driving conditions.

Precise power measurement is a critical aspect of performance optimisation, and inertia dynamometers excel in this area, delivering accuracy within 0.1% of engine performance.

This level of precision allows engineers to fine-tune engine power output, resulting in significant improvements in performance. Inertia dynamometers achieve this accuracy through measuring the force exerted on a load cell, which is directly proportional to the absorbed power.

Accurate calculations of torque and speed provide a realistic simulation of dynamic driving conditions, enabling the detection of even the smallest increments in power output.

Inertia dynamometers utilise the principle of inertia to measure the force exerted, providing highly accurate data on engine performance.

Measuring the acceleration rate of a known mass load, directly proportional to the torque and speed of the engine, achieves this. The resulting data is then used to calculate the revolutions per minute (RPM) and power output, enabling engineers to optimise engine performance with precision.

With the ability to measure power output with such accuracy, inertia dynamometers have become a vital tool in the development of high-performance engines.

Optimising engine performance is a delicate balancing act, where even the slightest adjustments can have a significant impact on total output.

Inertia dynamometers play a vital role in this process, enabling precise engine optimisation by measuring performance within 0.1% of engine performance. This level of accuracy allows for the detection of small performance increments, which can be critical in high-speed testing and racing applications.

Engineers can identify and address previously unknown areas for improvement using inertia dynamometers.

They can fine-tune engine components and settings for faster lap times on the racetrack. Inertia dynamometers provide a more thorough insight into engine behaviour, leading to more effective optimisation.

Real-time performance measurement is possible using load cells and strain gauges to collect accurate data.

Data analysis is quick and efficient with data acquisition systems and dynamometers that excel in testing engines, allowing for precise adjustments to RPM and horsepower.

Engine performance efficiency is a vital aspect of modern engine design, as even slight refinements can have a significant impact on fuel economy and total vehicle performance.

Inertia dynamometers provide accurate measurements of engine performance, enabling engineers to optimise engine performance and make targeted improvements. This precision enables the identification of areas for improvement, resulting in improved engine performance and increased fuel efficiency.

As engineers strive to refine engine performance, accurate and realistic testing methods are crucial.

Inertia dynamometers play a vital role in achieving precision and realism in high-speed testing.

Inertia dynamometers provide precise power measurements, focusing on acceleration and drum spool-up speed, thus ensuring accurate results.

These dynamometers initiate testing above idle position and progress to maximum RPM, simulating dynamic driving conditions for precise power measurement.

The combination of clutch and gearbox in inertia dynos allows for precise torque calculation, enabling improvement in areas previously unknown.

Inertia dynos can measure performance within 0.1% of engine performance, detecting small performance increments.

They prioritise realism, replicating actual load conditions and offering insights into engine performance in real-world driving scenarios.

Three key trends will transform the landscape of high-speed testing efficiency with inertia dynamometers.

The integration of advanced digital systems enables real-time data analysis and improved precision, allowing for more informed decision-making and optimised testing protocols. Miniaturisation of inertia dynamometer components increases portability, making high-speed testing more accessible to a wider range of industries and applications.

The development of sustainable and eco-friendly inertia dynamometer technologies plays a vital role in reducing the environmental impact of high-speed testing, aligning with the growing emphasis on green technology.

Advancements in materials science and electronics refine the accuracy, reliability, and durability of inertia dynamometers, further improving the efficiency of high-speed testing. As inertia dynamometers continue to be adopted in emerging industries, such as electric vehicles and renewable energy, innovation and growth in high-speed testing efficiency accelerate, driving the industry towards a more efficient and sustainable future.

Improving Efficiency in High-Speed Testing with Inertia Dynamometers

High-Speed Testing Challenges

Guaranteeing the reliability and performance of engines and transmissions relies heavily on high-speed testing. However, this poses significant challenges, including the need for precise control over testing parameters, accurate measurement of power and torque, and minimising testing time and cost.

Inertia Dynamometer Fundamentals

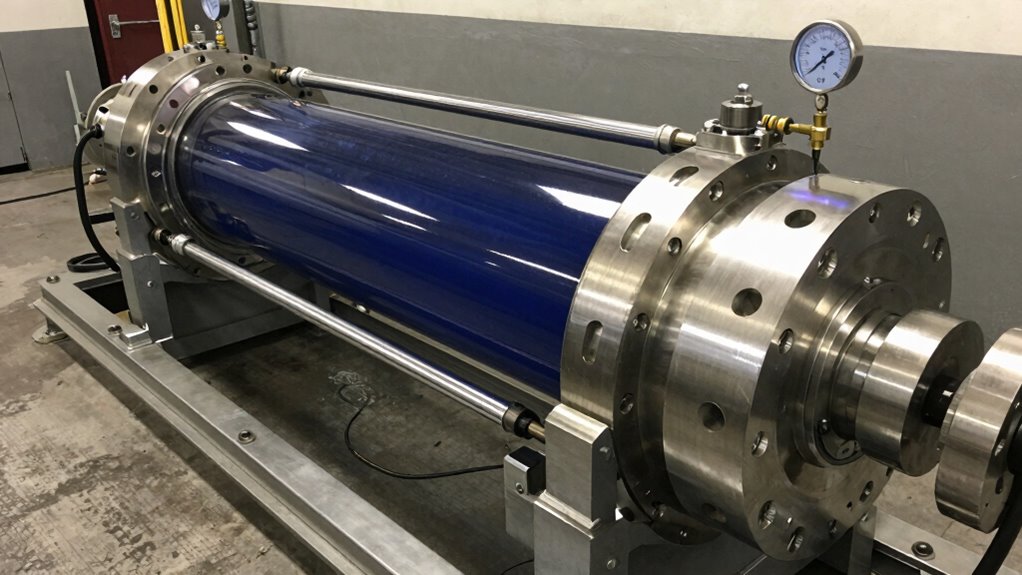

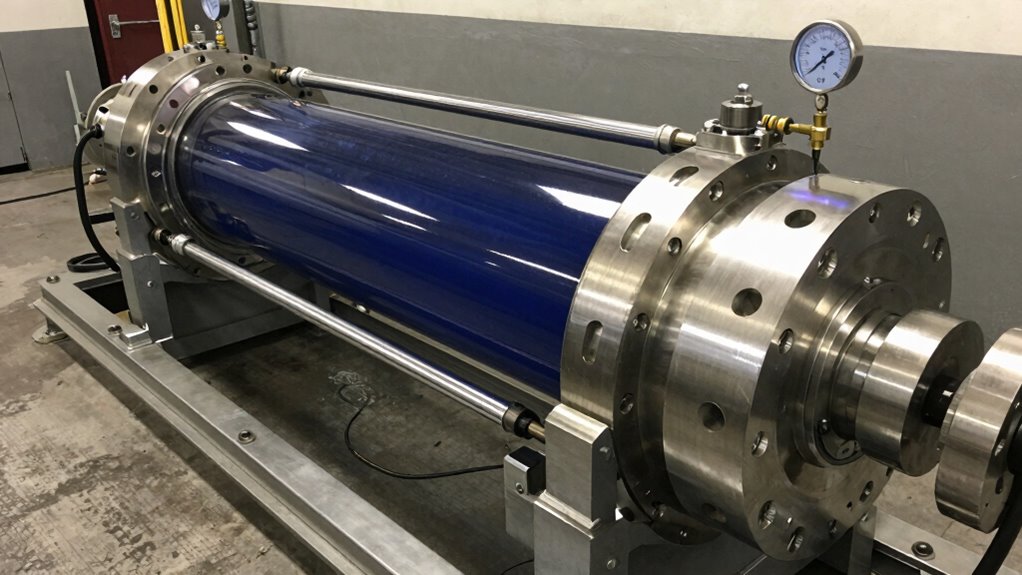

Hyper Power utilise inertia dynamometers, a type of testing equipment that measures the power output of an engine or transmission by absorbing and measuring the inertia of a rotating shaft. They consist of a rotor, bearings, and a housing, and operate on the principle of conservation of angular momentum.

Measuring Power with Inertia Dynos

Inertia dynamometers measure power by calculating the rate of change of angular momentum of the rotor. This is achieved by measuring the rotor's acceleration and deceleration, and then calculating the corresponding torque and power output.

Benefits of High-Speed Testing Efficiency

Efficient high-speed testing is vital for reducing testing time and cost, while improving the accuracy and reliability of test results. This enables manufacturers to accelerate product development, reduce warranty claims, and improve customer satisfaction. If you have any questions about how Hyper Power can help you achieve efficient high-speed testing, please contact us about our Custom Dyno Solutions, Installation and Setup, Training and Certification, Technical Support and Maintenance, Software Updates and Upgrades, Diagnostics and Performance Analysis, Rental Services, Dynamometer Testing Services, and Accessories and Parts.

Inertia Dyno Advantages Over Others

Inertia dynamometers offer several advantages over other types of testing equipment, including high accuracy, rapid testing capabilities, and low maintenance costs. They are also highly versatile and can be used to test a wide range of engines and transmissions.

Performance Optimization with Inertia Dynos

Inertia dynamometers enable performance optimisation by providing accurate and reliable data on engine and transmission performance. This data can be used to fine-tune engine and transmission designs, optimise power output, and reduce fuel consumption.

Enhancing Engine Performance Efficiency

Inertia dynamometers play a critical role in enhancing engine performance efficiency by providing accurate data on power output, fuel consumption, and emissions. This enables manufacturers to develop more efficient engines that reduce fuel consumption and emissions.

Precision and Realism in Testing

Inertia dynamometers guarantee precision and realism in testing by simulating real-world driving conditions and providing accurate data on engine and transmission performance. This enables manufacturers to develop products that meet customer expectations and regulatory requirements.

Future of High-Speed Testing Efficiency

The future of high-speed testing efficiency lies in the development of advanced inertia dynamometer technologies that can simulate increasingly complex driving scenarios and provide even more accurate and reliable data on engine and transmission performance. To learn more about how Hyper Power is driving innovation in high-speed testing, please contact us about our Custom Dyno Solutions, Installation and Setup, Training and Certification, Technical Support and Maintenance, Software Updates and Upgrades, Diagnostics and Performance Analysis, Rental Services, Dynamometer Testing Services, and Accessories and Parts.

Conclusion

Inertia dynamometers are vital for improving efficiency in high-speed testing, enabling manufacturers to reduce testing time and cost, while improving the accuracy and reliability of test results. Their high accuracy, rapid testing capabilities, and low maintenance costs make them an indispensable tool for optimising engine and transmission performance. If you're interested in learning more about how Hyper Power can help you achieve efficient high-speed testing, please contact us about our Custom Dyno Solutions, Installation and Setup, Training and Certification, Technical Support and Maintenance, Software Updates and Upgrades, Diagnostics and Performance Analysis, Rental Services, Dynamometer Testing Services, and Accessories and Parts.

Hydraulic dynos prevent catastrophic field failures—but most heavy industry operators still skip this critical step. Learn why.

Most diesel dyno operators ignore this—and it costs them thousands in failed runs and wasted data.

Stop wasting money on road testing. One dyno investment eliminates comebacks, builds loyalty, and outpaces competitors. Here’s why your workshop needs it.

Diesel turbo lag isn’t inevitable—modern dyno diagnostics reveal the hidden culprits stealing your power. Find out what your engine is hiding.

Fleet operators are throwing money away. Dynos reveal what road tests miss—and how much you’re losing.

Water testing won’t reveal what dyno testing exposes. Learn why engine builders skip this step at their peril.

Tractor performance tests reveal what manufacturers won’t tell you. See how dynamometer data exposes hidden inefficiencies in your equipment.

Diesel engine testing mistakes cost thousands monthly. Learn what separates thriving operations from regulatory nightmares.

No posts found!