How Dynamometers Enhance Engine Diagnostics and Testing

Necessitating precise measurements, dynamometers unlock the secrets of engine performance, but what else can they reveal about engine diagnostics and testing?

To decide on the optimal time for upgrading your dynamometer system, evaluate key performance metrics, maintenance expenses, and technological advancements in the sector. Concentrate on improving precision and efficiency in chassis testing.

Evaluate the system's capabilities, performance features, and potential for future expansion. Select upgrade packages that suit your requirements, such as data acquisition systems (DAS) that enhance data gathering. Enhance sensor technology to boost data accuracy and dependability.

Integrate real-time displays for immediate feedback. Optimise testing procedures for increased efficiency. Ensure reliable data collection and contemplate integrating a weather station for precise outcomes. Upgrading testing precision and analytical tools is crucial.

Validate compatibility and follow a seamless installation process for effortless integration. By considering these aspects, you can make well-informed choices when enhancing your dynamometer system effectively.

Determining the Optimal Time to Upgrade Your Dynamometer System

Deciding when to upgrade your dynamometer system involves evaluating performance metrics, industry advancements, and maintenance costs. For chassis dynamometer testing, accuracy, reliability, and efficiency are crucial. Regularly assessing these metrics helps identify any shortcomings that may necessitate an upgrade. It is also important to stay informed about industry advancements and regulatory changes affecting testing requirements.

Monitoring maintenance costs, downtime, and testing throughput provides insights into whether your current system meets your needs effectively. High maintenance costs or frequent downtime may indicate the need for an upgrade. Consulting with experts can help evaluate the return on investment, scalability, and compatibility of potential upgrade options. Strategic planning of upgrades to align with budget cycles and technological advancements ensures efficient and up-to-date chassis dynamometer testing.

For example, considering an upgrade to a modern chassis dynamometer system like the HORIBA MEXA-1000 series can enhance testing efficiency and accuracy. These systems offer advanced features such as real-time data monitoring and automated testing procedures, improving overall performance. Additionally, regular software updates and calibration services provided by manufacturers like HORIBA can keep your system up to date and compliant with regulatory standards.

When considering upgrading your dynamometer system, it's important to start by evaluating the system requirements.

This involves examining the system's capacity, analyzing performance tools, and considering future scalability needs.

System Capacity Assessment

Evaluating the power output capacity of your current dynamometer system is crucial to ensure precise and effective testing procedures. When assessing your system, consider factors such as its maximum power output, peak torque capabilities, and rotational speed range to meet testing requirements accurately.

It is essential to ensure compatibility with various vehicle types and engine configurations for versatility in testing. Your system should also adhere to industry standards for emissions testing and data acquisition to guarantee reliable results.

Additionally, it is important to explore the potential for system expansion to accommodate future testing needs and maintain long-term efficiency. Understanding your dynamometer system's capacity thoroughly can help optimise testing procedures and be prepared for evolving testing demands in the automotive industry.

Performance Analysis Tools

Have you considered utilising performance analysis tools to assess your current dynamometer system's capabilities and pinpoint areas for enhancement based on data and testing needs? These tools delve into factors such as maximum power capacity, torque range, speed capabilities, and data acquisition features to identify where upgrades might be required. Understanding the constraints of your existing setup enables you to make well-informed decisions on enhancements that will enhance testing precision and efficiency. Below is a table outlining key considerations for evaluating your system requirements:

| Factors to Consider | Description | Importance Level |

|---|---|---|

| Maximum Power Capacity | Establishes the upper limit of power the system can handle | High |

| Torque Range | Indicates the range of torque values the system can measure | Medium |

| Speed Capabilities | Specifies the maximum speed for conducting tests | High |

Future Scalability Considerations

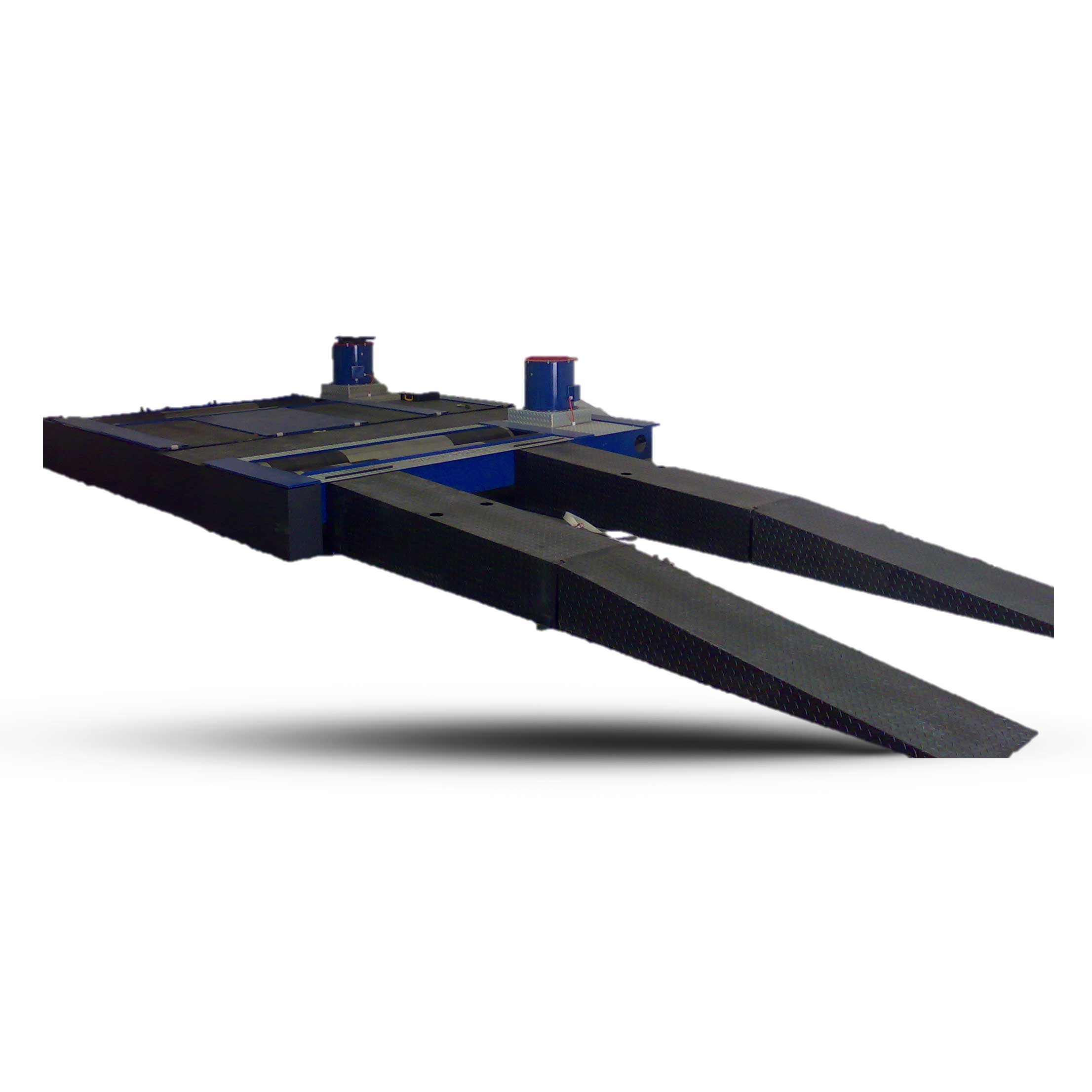

Assessing the potential for future scalability in a dynamometer system requires a detailed examination of current testing requirements and forecasts for growth. Chassis dynamometers are crucial for ensuring vehicle performance and durability, underscoring the need to evaluate the system's ability to handle increasing test volumes and changing test parameters.

Enhancing the dynamometer with additional sensors, data acquisition capabilities, and software updates can boost its performance and flexibility to adapt to future advancements in vehicle technology and regulatory standards. Planning for potential system expansions or modifications is essential to meet evolving testing criteria and industry developments, ensuring sustained compatibility and effectiveness in testing procedures.

When upgrading your dynamometer system, it's important to evaluate the characteristics, compatibility, and installation process of the upgrade kits available. These factors play a vital role in determining the effectiveness and performance of your improved dynamometer setup.

Upgrade Kit Features

Enhance your dynamometer system with the appropriate improvement kit option tailored to your performance needs. The DAS upgrade kit options cater to different dynamometer requirements, providing full sensor utilisation and control features for improved performance. For those seeking basic upgrades, the Mini DAS kit offers key components for entry-level enhancements. If you prefer a streamlined approach, the Integrated DAS kit combines engine RPM and wideband Lambda in one housing for efficient data acquisition. Each kit includes important components such as a data acquisition system, remote control, and software to guarantee optimal functionality. Meeting the system requirements for the Advanced Dyno Station is vital to ensure peak performance of your chosen upgrade kit.

| Upgrade Kit Option | Features |

|---|---|

| DAS Upgrade Kit | Full sensor utilisation and control features |

| Mini DAS Upgrade Kit | Entry-level basic dynamometer upgrades |

| Integrated DAS Upgrade Kit | Combines engine RPM and wideband Lambda in one housing |

Enhancing your dynamometer system with the right upgrade kit is crucial to maximise performance. The full sensor utilisation and control features in the DAS Upgrade Kit enable precise data collection and analysis, leading to more accurate results. For those starting out, the Mini DAS Upgrade Kit provides a solid foundation with essential components for basic enhancements, setting the stage for future improvements. Meanwhile, the Integrated DAS Upgrade Kit simplifies the setup by combining engine RPM and wideband Lambda in a single housing, streamlining the data acquisition process.

By investing in an upgrade kit, you not only improve the functionality of your dynamometer system but also enhance its overall efficiency. For instance, the Integrated DAS Upgrade Kit's consolidation of engine RPM and wideband Lambda sensors reduces clutter and simplifies the setup, allowing for smoother data acquisition. Additionally, the remote control and software included in each kit empower you to monitor and adjust settings with ease, ensuring seamless operation and accurate results. These components work together to optimise your dynamometer's performance and deliver precise measurements.

Selecting the right upgrade kit for your dynamometer system is essential to achieve consistent and reliable results. For users looking to enhance their system gradually, the Mini DAS Upgrade Kit provides fundamental improvements without overwhelming complexity. On the other hand, the Integrated DAS Upgrade Kit offers a more integrated solution for streamlined data acquisition, perfect for those seeking efficiency in their testing processes. Consider your specific needs and performance goals to choose the upgrade kit that best aligns with your requirements and budget.

Compatibility Considerations

Exploring the specific requirements and performance objectives of your dynamometer system is crucial when choosing the right upgrade kit option. To ensure a seamless integration, it is essential to carefully assess compatibility considerations. Here are some key factors to keep in mind when upgrading your chassis dynamometer:

For example, when upgrading a chassis dynamometer system from a basic model to a more advanced version, ensuring that the new components are compatible with the existing setup is essential to avoid any disruptions in testing procedures.

Exploring the installation process for upgrade kit options entails examining the specific components and functionalities needed to enhance your dynamometer system's performance. Whether you choose the full sensor utilisation and control features of the DAS upgrade kit or begin with the basic Mini DAS for initial upgrades, each kit is crafted to elevate your dynamometer's capabilities. The Advanced Dyno Station elevates the experience with a database for vehicle measurement history and real-time display, while the Drive SIM module enables simulation of real road conditions for precise emissions testing. Remember, each upgrade kit includes essential components like the data acquisition system, remote control, and software for smooth integration into your existing setup. Be sure to select the kit that aligns best with your requirements for a seamless installation process.

Understanding the Components: The upgrade kits encompass key elements such as the data acquisition system, remote control, and software. These components work in harmony to enhance the functionality and performance of your dynamometer system. For instance, the DAS upgrade kit provides advanced sensor capabilities and control features, enabling precise data collection and analysis for optimal results.

Selecting the Right Kit: It is crucial to choose the upgrade kit that best fits your specific needs and objectives. For instance, if you require comprehensive data collection and analysis, the DAS upgrade kit with its advanced features would be a suitable choice. On the other hand, if you are looking for a more streamlined approach, the Mini DAS kit offers a basic yet effective solution for initial upgrades.

Enhancing Capabilities: By investing in an upgrade kit, you are not only improving the performance of your dynamometer system but also opening up possibilities for more advanced functionalities. For example, the Advanced Dyno Station provides a comprehensive database for storing vehicle measurement history, allowing for in-depth analysis and comparison of data over time.

Ensuring Seamless Integration: One of the key benefits of these upgrade kits is their seamless integration into your existing dynamometer setup. With essential components and user-friendly software included in each kit, the installation process is made easier, ensuring minimal disruption to your operations. This streamlined integration enhances efficiency and allows you to start benefiting from the upgraded features promptly.

Benefits of Weather Station Integration in Dynamometer Systems

Incorporating a weather station into dynamometer systems is essential for obtaining precise test results. For example, the Davis Instruments Vantage Pro2 Weather Station is a reliable option known for its accurate temperature sensing capabilities.

By integrating a weather station, engineers can ensure that the test results are not skewed by external factors like humidity or barometric pressure. This is particularly important when evaluating engine performance to guarantee the reliability of the data collected.

Weather station data allows for a more accurate simulation of real-world conditions during testing. This level of realism is crucial for industries like automotive engineering, where understanding how environmental factors affect vehicle performance is key to developing efficient and reliable products.

Improving simulation capabilities in your dynamometer system is like fine-tuning a musical instrument before a big performance.

It's all about achieving enhanced testing accuracy and advanced data analysis to reveal the full potential of your vehicle evaluations.

Advanced Control Features for Enhanced Testing Precision

By incorporating sophisticated control functionalities, upgrading your dynamometer system can significantly boost simulation capabilities, resulting in improved testing accuracy. When striving for superior testing precision, consider these essential enhancements:

Advanced Data Analysis

Advanced data analysis plays a crucial role in enhancing the accuracy and efficiency of simulation capabilities in dynamometer systems. By utilising advanced data analysis tools, such as those integrated into modern dynamometers and testing equipment, engineers can enhance simulation accuracy and predict performance more precisely.

Integrating real-world data into simulations not only confirms system functionality but also boosts testing efficiency. In-depth analysis of engine behaviours using these tools enables fine-tuning for optimal performance and development.

Furthermore, advanced simulation tools enable virtual testing under various operating conditions, providing insights crucial for troubleshooting, optimisation, and future design improvements. Embracing advanced data analysis is essential for unlocking the full potential of dynamometer systems in today's dynamic testing environments.

Upgrading the DAS Data Acquisition System for dynamometers greatly enhances sensor utilization and control capabilities. When considering enhancing your dynamometer system, focusing on improving your DAS can have a significant impact. Here are three key aspects to consider:

Upgrading your DAS with the latest equipment can unlock the full potential of your dynamometer. By allowing comprehensive data collection through engine RPM and wideband Lambda measurements in a single housing, you can enhance performance monitoring and analysis.

Integrating various parameters like turbo pressure and throttle valve position through a single cable simplifies data acquisition. This efficiency not only saves time but also ensures precise and dependable data for your dynamometer system.

Different upgrade kits offer specific features tailored to suit your dynamometer's unique needs. Whether you choose an entry-level Mini DAS kit or a more advanced system, there are options available to cater to different requirements and budgets.

Enhancing Sensor Utilisation for Dynamometer Systems

Enhancing sensor utilisation plays a vital role in optimising the performance and efficiency of dynamometer systems. By upgrading to a DAS integrated kit for engine RPM and wideband Lambda measurements, you can significantly improve sensor capabilities. This upgrade ensures that sensors are fully utilised, providing extensive control options for enhanced system performance. Starting with a basic upgrade like a Mini DAS kit can lay the foundation for more advanced enhancements.

Maximising data collection efficiency with advanced sensor options tailored to specific testing requirements is essential for improving sensor utilisation. This upgrade not only enhances testing accuracy and reliability but also enhances overall system performance. Upgrading sensor utilisation is a strategic decision that can bring significant long-term benefits, making your dynamometer system more effective and reliable. Utilise your sensors to their full potential to unleash the capabilities of your dynamometer system.

Implementing Real-Time Value Displays

To enhance dynamometer system functionality, integrating real-time value displays is crucial for providing immediate feedback on engine performance parameters. These displays offer insights into vital metrics such as engine speed, power, torque curves, and air/fuel ratio, improving the testing experience by enabling users to monitor data effectively.

Here are three ways real-time value displays can enhance your testing process:

Implementing real-time value displays can transform your testing procedures, offering valuable insights and improving overall efficiency.

Maximising Testing Efficiency

Maximising testing efficiency involves enhancing data collection and analysis processes by integrating advanced dynamometer systems. By upgrading your system, you can streamline operations, boost productivity, and achieve quicker testing turnaround times. An advanced dynamometer system offers features such as real-time monitoring, customisable testing parameters, and remote access, enabling better control over the testing process. To demonstrate the advantages of maximising testing efficiency, consider the following comparison table:

| Features | Benefits |

|---|---|

| Real-time monitoring | Prompt feedback for adjustments |

| Customisable parameters | Tailored testing for specific requirements |

| Remote access | Manage testing processes from any location |

| Enhanced reliability | Decreased downtime, consistent outcomes |

Efficiency is crucial in the competitive market, where meeting industry standards is vital for success. Upgrading your dynamometer system to optimise testing efficiency not only ensures dependable results but also keeps you ahead of the curve in the swiftly changing landscape of testing operations.

Ensuring Accurate Parameter Collection

Ensuring precise testing outcomes requires the careful gathering of crucial parameters, such as turbo pressure and throttle valve position. To accomplish this effectively, consider the following:

In conclusion, upgrading your dynamometer system is essential for maximizing testing efficiency and ensuring fundamental parameter collection. By identifying the optimal upgrade time, assessing system requirements, and selecting the right upgrade kit options, you can enhance simulation capabilities and increase sensor utilization.

Incorporating a weather station and implementing real-time value displays are also crucial considerations. Overall, upgrading your dynamometer system will help you stay at the forefront of testing technology and achieve more precise results.

Guide Towards Further Learning:

Spark curiosity for more knowledge by inviting the reader to contact Hyper Dyno. Feel free to reach out to us if you have any questions about Dynamometer Products, Custom Solutions, Installation Setup, Training and Certification, Technical Support and Maintenance, Software Updates, Rental Services, Dynamometer Testing Services, and Accessories and Parts. Take action now and contact us!

Necessitating precise measurements, dynamometers unlock the secrets of engine performance, but what else can they reveal about engine diagnostics and testing?

Navigating the complexities of torque measurement requires a deep understanding of the underlying principles and mechanisms to ensure accurate results.

Precise control and optimization of engine performance await, but only for those who unlock the secrets of dynamometer-driven data analysis.

Gaining insight into the differences between inertia and brake dynamometers is crucial for ensuring accurate testing results in various industries.

Tapping into the precise measurement capabilities of dynamometers, uncover the secrets to optimizing fuel efficiency and slashing emissions in the automotive industry.

Witness the importance of rigorous safety protocols and best practices in dynamometer testing to avoid catastrophic failures and ensure accurate results.

Harnessing the nuances of precision measurement is crucial to avoiding costly errors in dynamometer testing, but what are the key factors to consider?

Witness the transformative power of dynamometers in unlocking your vehicle’s hidden performance potential, but only if you know how to harness their precision.

Hyper Power, the leading name in dynamometer solutions, offers unparalleled precision and reliability for all your performance testing needs.