How Dynamometers Enhance Engine Diagnostics and Testing

Necessitating precise measurements, dynamometers unlock the secrets of engine performance, but what else can they reveal about engine diagnostics and testing?

Ensuring dynamometer accuracy and precision is crucial in testing, as even minor errors or biases can significantly impact the reliability and validity of measurement results.

Factors such as sensor quality, environmental conditions, operator skill, and data acquisition systems all influence dynamometer accuracy.

To minimize measurement errors and biases, regular calibration, meticulous attention to detail, and proper maintenance are essential.

Testing professionals must grasp sensor technologies and errors to select appropriate sensing technologies and control environmental factors.

This enables them to guarantee accurate and reliable measurements.

As the complexity of dynamometer testing increases, it becomes increasingly vital to stay informed about the nuances of precision measurement.

By doing so, testing professionals can ensure the reliability and validity of their measurement results.

Accurate dynamometer measurements rely on a multitude of factors, each playing a vital role in verifying the reliability and precision of the data obtained.

The quality and type of sensing elements used, such as strain gauges or load cells, directly impact accuracy.

Environmental factors, including temperature, humidity, and vibration, can profoundly influence dynamometer accuracy, with even slight changes affecting measurement results.

The operator's skill level and experience are vital in achieving precise and reliable measurements, as trained operators can properly set up and operate the dynamometer.

The data acquisition system and software used also impact accuracy, with advanced systems providing more precise and reliable data and software features like filtering and averaging helping to reduce measurement noise and errors.

Grasping and controlling these factors enable users to guarantee the highest level of accuracy and precision in their dynamometer measurements, ultimately leading to reliable and actionable insights.

Calibration of dynamometers is the cornerstone of trust in precision-critical measurement, certifying accuracy and reliability.

The frequency of calibration depends on factors such as instrument use, environmental conditions, and the critical nature of the measurements.

Industries have varying calibration standards.

For instance, aviation and aerospace require precision calibration across a broad spectrum, often necessitating 10-15 calibration points.

In contrast, the automotive industry focuses on 5-8 points to capture engine performance and emissions subtleties.

Without calibration, dynamometers can lead to incorrect inferences and decisions, highlighting the importance of regular calibration to maintain precision and reliability.

Calibration detects and corrects any errors or biases in the measurement process, validating that measurements are consistent and comparable across different devices and environments.

Validating accurate and reliable measurements, calibration is the key to precision in dynamometer testing, providing a foundation for informed decision-making and confident results.

Environmental factors, including humidity and temperature, can profoundly impact dynamometer accuracy, making it vital to take into account these variables when operating and maintaining the device.

Regular calibration schedules are also pivotal to guarantee precision, as even slight deviations from optimal conditions can affect results. By acknowledging and addressing these environmental considerations, users can minimize errors and optimize dynamometer performance.

Operating a dynamometer in a controlled environment is crucial to guarantee accurate and reliable test results.

Environmental factors profoundly impact the accuracy and precision of dynamometer testing, making it imperative to consider these factors during the testing process. Precision in dynamometer testing requires controlling environmental conditions that can affect the test results.

Vibrations, electromagnetic interference, and air currents are environmental factors that can compromise the accuracy and precision of dynamometer testing.

These factors cause unwanted noise, signal distortion, and mechanical interference, leading to inaccurate test results.

To counteract these effects, operating the dynamometer in a controlled environment, such as a dedicated test cell or laboratory setting, is imperative.

Controlling these environmental factors ensures that test results accurately reflect the performance of the device or system being tested, ultimately contributing to the development of reliable and high-quality products.

In conjunction with vibrations, electromagnetic interference, and air currents, humidity and temperature are equally vital environmental factors to consider when operating a dynamometer.

These factors can substantially impact the accuracy and precision of dynamometer measurements. Temperature changes, for instance, cause thermal expansion and contraction of mechanical components, leading to measurement errors. Humidity, in contrast, corrodes or damages electrical connections and sensors, further compromising accuracy.

To ensure accurate measurements, dynamometers should operate within a controlled temperature range, typically between 15°C and 30°C, and humidity levels below 80%.

Regular cleaning and drying of the dynamometer's sensing elements and electrical connections help prevent humidity-related issues. Thermal shielding or insulation offsets temperature effects.

Some dynamometers are designed with environmental compensation features, which correct for temperature and humidity influences, but these must be calibrated and validated according to the manufacturer's specifications.

Controlling humidity and temperature enables dynamometer users to minimize errors and guarantee reliable, precise measurements.

Maintaining dynamometer accuracy and precision relies on adhering to regular calibration schedules, which must account for environmental factors that impact measurement reliability.

Temperature, humidity, and vibration are factors that affect dynamometer accuracy and precision, and calibration schedules should consider these. Dynamometers used in harsh environments, such as high-temperature or high-vibration settings, may require more frequent calibration to ensure accurate measurements.

Regular maintenance tasks, such as cleaning and lubricating moving parts, should be performed according to the manufacturer's schedule to prevent wear and tear that can impact calibration.

Calibration must be performed by trained personnel using certified reference standards to certify traceability and accuracy of measurements. A calibration interval of 6-12 months is commonly recommended, though this may vary depending on the specific dynamometer model, usage, and industry requirements.

Adhering to regular calibration schedules ensures that dynamometers provide accurate and precise measurements, vital for reliable testing and analysis.

Most dynamometer systems rely on sensors to convert mechanical parameters into electrical signals, making sensor technology a vital component of dynamometer accuracy.

The accuracy of a dynamometer is heavily dependent on the sensing technologies employed, as they directly impact the quality of the measurements obtained. Precise measurements are only possible when sensors accurately detect and convert mechanical parameters such as torque, speed, and vibration into electrical signals.

Different sensing technologies are suited for specific applications, and selecting the appropriate technology is crucial.

Strain gauge sensors, for instance, are commonly used for torque measurement, while optical encoders are used for speed measurement. Each sensing technology has its strengths and limitations, and understanding these is fundamental for guaranteeing accurate measurements.

Errors in sensor output can spread through the measurement chain, affecting the total accuracy of the dynamometer. Consequently, it is essential to carefully select and implement sensing technologies that meet the specific requirements of the application, and to verify that they are properly calibrated and maintained to guarantee precise measurements.

Accurate dynamometer measurements rely on meticulous attention to detail in minimising errors and biases.

Calibration of dynamometers is vital to guarantee that the instrument provides accurate and reliable data, with a typical uncertainty of ±0.5% to ±11.0% of the full-scale range.

Regular checks and maintenance of dynamometers can help detect and correct any errors or biases, such as sensor drift, signal noise or software malfunctions, which can lead to inaccurate measurements.

Environmental factors, such as temperature, humidity and vibration, can also affect dynamometer accuracy, and consequently, it is imperative to control and monitor these factors during testing to minimise measurement errors and biases.

The use of high-quality sensing elements, such as strain gauges or load cells, can help reduce measurement errors and biases, providing more accurate and reliable data.

Implementing these measures ensures the highest level of accuracy and reliability, ultimately leading to more reliable test results.

Data acquisition systems form the backbone of dynamometer testing, as they capture and process raw data from sensors, converting it into meaningful measurements that inform operator decisions.

Real-time data monitoring is a critical aspect of data acquisition, enabling operators to respond promptly to changes in testing conditions and guarantee accurate measurements.

A dynamometer's precision relies heavily on its data acquisition system (DAS), which captures, processes, and stores essential data from sensors and transducers to enable accurate and reliable measurement of torque, power, and speed.

The DAS plays a pivotal role in dynamometer testing, collecting data to facilitate precise measurement. A typical DAS consists of sensors, signal conditioning units, analogue-to-digital converters, and software for data analysis and visualisation, allowing for real-time data acquisition and data logging.

Modern DAS often feature high-speed sampling rates, advanced signal processing algorithms, and built-in calibration capabilities to guarantee precise and accurate data acquisition.

The choice of DAS depends on factors such as the type of dynamometer, testing application, and desired level of accuracy. Data acquisition systems can be customised to meet specific testing requirements, making them adaptable tools for diverse industries.

The success of dynamometer testing frequently hinges on the ability to monitor performance in real-time, as this capability enables instantaneous assessment of measurement data and swift identification and correction of errors or inconsistencies.

Advanced data acquisition systems make real-time data monitoring possible, sampling data at high frequencies, often up to 100 kHz, to capture transient events and guarantee accurate representation of the measured phenomenon.

These systems harmonize data from multiple sensors and channels, providing an exhaustive insight into the testing process and facilitating more accurate analysis.

Real-time data monitoring also enables implementation of safety protocols, such as automatic shutdown or warning systems, to prevent equipment damage or operator injury during testing.

Testing professionals can guarantee accuracy, precision, and reliability in their dynamometer testing through real-time data monitoring, ultimately leading to more informed decision-making and improved product development.

When dynamometer measurements deviate from expected values, troubleshooting and error correction become crucial to guarantee accurate and reliable results.

Calibration errors, a common source of inaccuracy, can be corrected through comparison with a reference standard, adjusting the instrument accordingly to certify accuracy within ±1% of the full-scale range.

Signal noise, another potential issue, can be addressed by employing low-pass filters, shielding cables, and verifying proper grounding, resulting in a signal-to-noise ratio of at least 10:1.

Sensor drift can be identified through monitoring changes in the dynamometer's zero-point offset, and correcting it through regular zeroing procedures or replacement of the sensing element.

Incorrect dynamometer setup can lead to errors of up to 5% in torque measurement, highlighting the importance of following manufacturer guidelines and consulting user manuals.

Regular inspection and maintenance of the dynamometer's mechanical components, such as bearings and gears, can prevent mechanical errors and certify accurate measurements.

Identifying and addressing these potential errors enables users to obtain precise and reliable results from their dynamometers.

Beyond fundamental calibration principles, advanced techniques and methods ensure the highest level of accuracy and precision in dynamometer measurements.

Precision instruments, such as laser interferometers, validate accurate measurements of displacement and velocity. The National Institute of Standards and Technology (NIST) provides guidelines for dynamometer calibration, involving a series of tests to verify the instrument's accuracy and precision.

End-to-end calibration is a common method, involving measurement of the dynamometer's output signal against a known input force or torque.

Multi-point calibration is another advanced technique, calibrating the dynamometer at multiple points across its measurement range to confirm accuracy and linearity. Some dynamometer manufacturers offer advanced calibration services, including custom calibration protocols, precision alignment, and certification to international standards such as ISO 17025.

These advanced calibration techniques and methods confirm the highest level of accuracy and precision in dynamometer measurements, guaranteeing reliable and consistent results.

Optimising dynamometer performance and reliability is pivotal to guaranteeing accurate and precise measurements in testing applications.

Regular calibration of dynamometers is indispensable, with a minimum of 10-15 calibration points recommended for aviation and aerospace applications.

Proper installation, alignment, and coupling of dynamometers with the test object are also paramount, as misalignment errors can potentially exceed 10% of the measured value.

Environmental factors such as temperature, humidity, and vibration must be controlled, and temperature compensation mechanisms should be implemented to minimise their impact on dynamometer performance.

Quality control measures, such as certification and auditing, help guarantee the reliability and precision of dynamometer measurements, reducing the risk of faulty or misleading data.

The choice of dynamometer type and configuration should be based on specific testing requirements, considering factors such as load type, speed range, and torque measurement range.

Optimising dynamometer performance and reliability enables users to guarantee accurate and precise measurements, and ultimately, make informed decisions based on reliable data.

Ensuring Dynamometer Accuracy and Precision in Testing

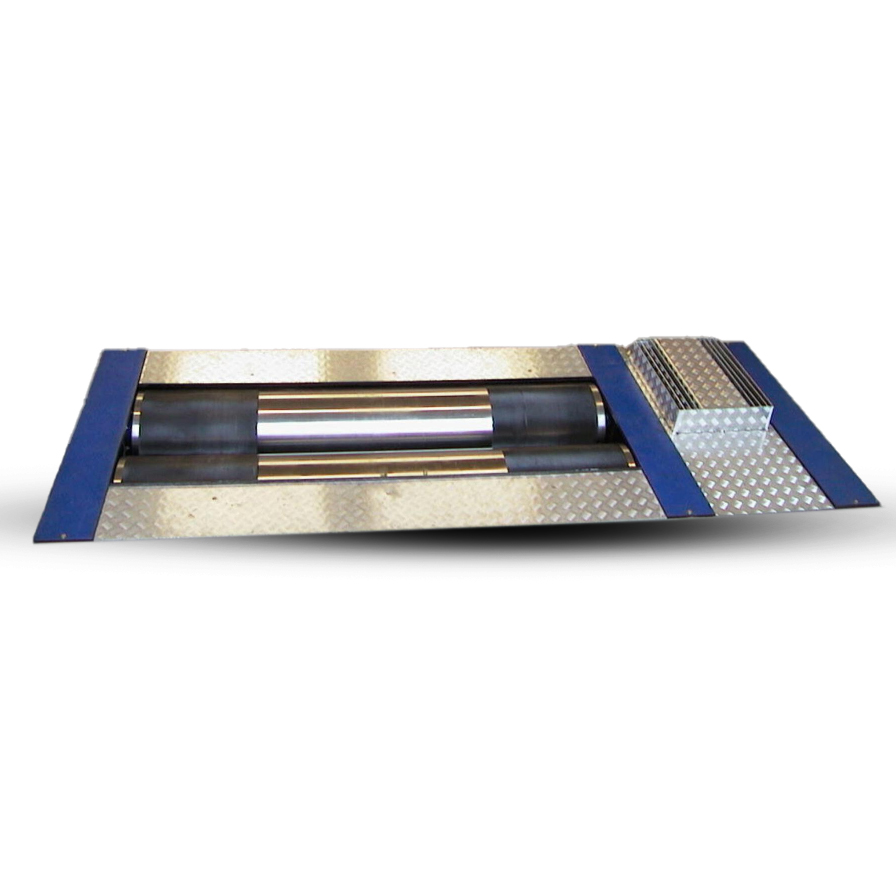

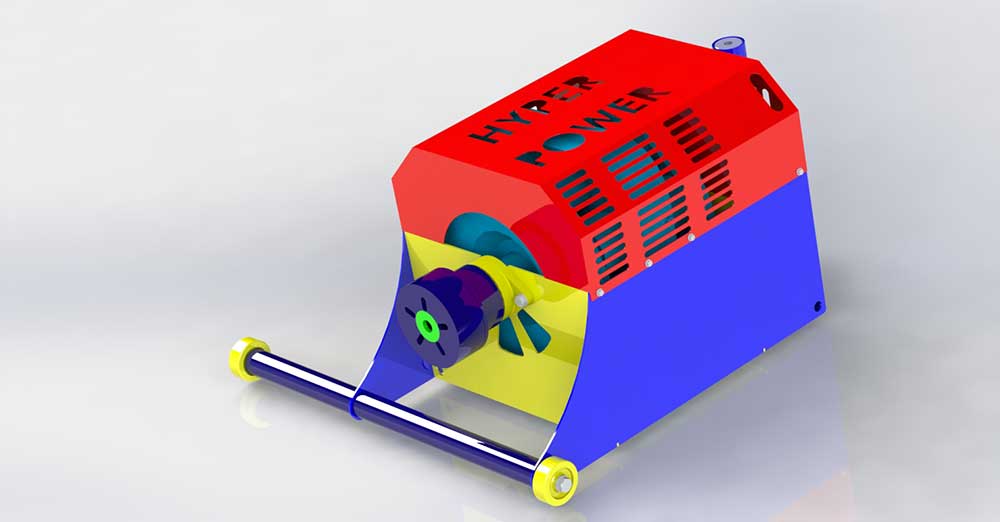

At Hyper Power, we understand that dynamometer accuracy is influenced by a range of factors, including sensor selection, data acquisition systems, and environmental conditions. It is crucial to grasp these factors to minimize measurement errors and guarantee precise results. Furthermore, the type of dynamometer, its mechanical design, and the testing protocol employed can also impact accuracy.

Calibration: The Key to Precision

Calibration is a pivotal step in guaranteeing dynamometer accuracy. It involves comparing the dynamometer's output to a known reference standard to establish a correlation between the two. Regular calibration is necessary to maintain precision, as dynamometers can drift over time due to wear and tear, temperature changes, or other environmental factors. If you have any questions about our Custom Dyno Solutions, please do not hesitate to contact us.

Environmental Considerations and Maintenance

Environmental factors such as temperature, humidity, and vibration can affect dynamometer accuracy. It is imperative to maintain a controlled environment and guarantee the dynamometer is properly installed, mounted, and secured. Regular maintenance, including cleaning and lubrication, is also necessary to prevent mechanical wear and tear. Our Installation and Setup services can ensure your dynamometer is properly installed and configured.

Grasping Sensor Technologies and Errors

Dynamometers employ a range of sensor technologies, including strain gauges, piezoelectric, and optical sensors. Each sensor technology has its strengths and weaknesses, and grasping their limitations is vital to minimizing measurement errors. Sensor errors can arise from factors such as thermal effects, electromagnetic interference, and mechanical stress. Our Training and Certification programme can help you understand sensor technologies and minimize measurement errors.

Minimizing Measurement Errors and Biases

Measurement errors and biases can be minimized by selecting the appropriate sensor technology, optimizing the testing protocol, and using data acquisition systems with high resolution and low noise. Furthermore, statistical methods can be applied to reduce the impact of measurement errors and biases. Our Technical Support and Maintenance team can assist you in minimizing measurement errors and biases.

The Role of Data Acquisition Systems

Data acquisition systems play a pivotal role in dynamometer testing, as they convert the raw sensor data into a usable format. The selection of a suitable data acquisition system is imperative, as it can affect the accuracy and precision of the results. Our Software Updates and Upgrades can ensure your data acquisition system is up-to-date and running smoothly.

Troubleshooting and Error Correction

Troubleshooting and error correction are imperative steps in guaranteeing dynamometer accuracy. Identifying and addressing errors promptly can prevent the propagation of inaccuracies and guarantee reliable results. Our Diagnostics and Performance Analysis services can help you troubleshoot and correct errors.

Advanced Calibration Techniques and Methods

Advanced calibration techniques and methods, such as multi-point calibration and uncertainty analysis, can be employed to further improve dynamometer accuracy and precision. These techniques provide a more in-depth understanding of the dynamometer's performance and can help identify potential sources of error. Our Rental Services can provide you with access to advanced calibration techniques and methods.

Optimizing Dynamometer Performance and Reliability

Optimizing dynamometer performance and reliability requires a thorough understanding of the factors influencing accuracy and precision. By selecting the appropriate sensor technology, optimizing the testing protocol, and employing advanced calibration techniques, dynamometers can be optimized to provide reliable and accurate results. Our Dynamometer Testing Services can help you optimize your dynamometer's performance and reliability.

Conclusion:

Guaranteeing dynamometer accuracy and precision requires a multifaceted approach that encompasses factor identification, calibration, environmental control, and maintenance. By grasping the sources of error and implementing corrective measures, dynamometers can provide reliable and accurate results, thereby enhancing the validity of testing and research outcomes. If you have any questions about our Accessories and Parts, please do not hesitate to contact Hyper Power.

Necessitating precise measurements, dynamometers unlock the secrets of engine performance, but what else can they reveal about engine diagnostics and testing?

Navigating the complexities of torque measurement requires a deep understanding of the underlying principles and mechanisms to ensure accurate results.

Precise control and optimization of engine performance await, but only for those who unlock the secrets of dynamometer-driven data analysis.

Gaining insight into the differences between inertia and brake dynamometers is crucial for ensuring accurate testing results in various industries.

Tapping into the precise measurement capabilities of dynamometers, uncover the secrets to optimizing fuel efficiency and slashing emissions in the automotive industry.

Witness the importance of rigorous safety protocols and best practices in dynamometer testing to avoid catastrophic failures and ensure accurate results.

Harnessing the nuances of precision measurement is crucial to avoiding costly errors in dynamometer testing, but what are the key factors to consider?

Witness the transformative power of dynamometers in unlocking your vehicle’s hidden performance potential, but only if you know how to harness their precision.