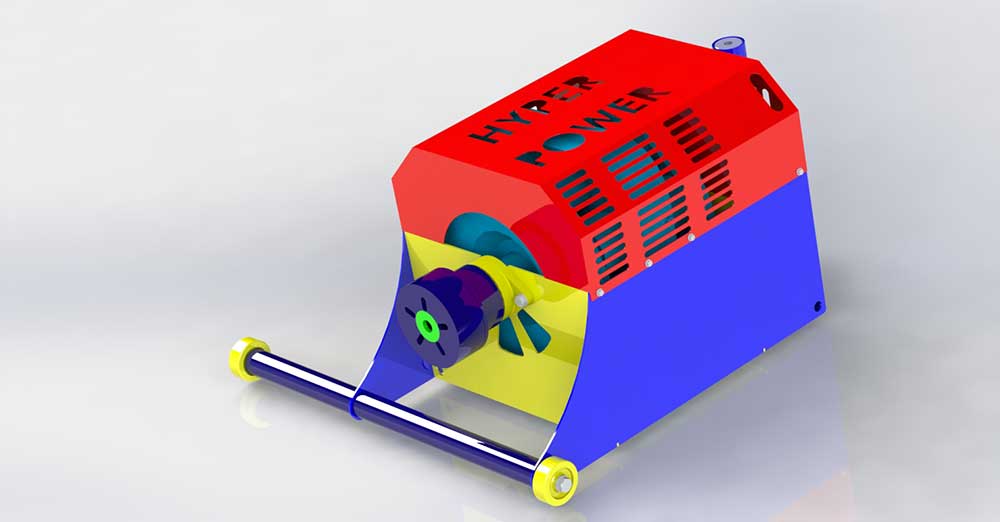

Why Top Tuning Shops Choose Hyper Power Dynamometers

Tune into the unparalleled precision and power optimization that top tuning shops crave with Hyper Power Dynamometers – setting a new standard in performance enhancement.

To understand your dynamometer's software, it is crucial to grasp its role in engine testing, real-time data monitoring, torque measurement, customisable test parameters, and data logging capabilities.

Torque measurement directly reflects engine performance, assesses power output, identifies areas for improvement, and enhances engine efficiency.

Customisable test parameters allow adjustment of speed, load, and duration to provide precise results. Data logging captures information over time for trend analysis and issue detection. Graph plotting visually presents results for better comprehension.

Familiarising yourself with menu navigation and button functions equips users for efficient testing and analysis. Optimising sensor calibration ensures accurate performance data. By becoming familiar with these functions, you can maximise the potential of your dynamometer software.

Overview of Dynamometer Software

Dynamometer software plays a crucial role in engine testing by providing real-time data monitoring and analysis capabilities. One of its primary functions is to measure torque, essential for evaluating an engine's performance. This software enables engineers to accurately determine the rotational force generated by the engine, offering valuable insights into its power output and efficiency.

Customisable test parameters, graph plotting, and data logging are key features of dynamometer software, enhancing testing capabilities by allowing users to adapt the testing process to their specific requirements. The software interfaces empower users to modify test parameters, establish test protocols, and conveniently review test results. By integrating with dynamometer hardware, this software ensures precise control over testing conditions and precise data collection, leading to reliable and consistent performance assessments. Additionally, advanced software options provide tools for refining engine performance and optimising test outcomes, making dynamometer software a valuable asset in engine testing.

Importance of Torque Measurement

Measuring torque is vital in engine testing as it provides a direct indication of the engine's performance. For instance, by accurately measuring the rotational force generated by the engine, engineers can assess its power output and efficiency levels. This information is crucial for identifying areas of improvement and optimising the engine's overall performance.

Customisable Test Parameters

The ability to customise test parameters in dynamometer software is essential for tailoring the testing process to specific needs. For example, users can adjust parameters such as speed, load, and duration to simulate various operating conditions and performance scenarios. This flexibility allows for comprehensive testing and analysis, leading to more accurate and insightful results.

Data Logging and Analysis

The feature of data logging in dynamometer software enables users to record and analyse test data over time. For instance, by logging parameters such as torque, speed, and power output during testing, engineers can track performance trends and identify potential issues. This data is valuable for making informed decisions regarding engine optimisation and maintenance.

Graph Plotting for Visual Representation

Graph plotting capabilities in dynamometer software provide a visual representation of test data, making it easier to interpret and analyse results. For example, plotting torque versus engine speed can help identify performance characteristics such as peak torque and power levels. Visualising data in this way enhances understanding and facilitates comparison between different test runs.

Recommendation: DynoMax Software

For comprehensive dynamometer software capabilities, DynoMax is a highly recommended option. With its user-friendly interface, customisable test parameters, and advanced data analysis tools, DynoMax offers a comprehensive solution for engine testing needs. Whether conducting basic performance evaluations or in-depth research and development projects, DynoMax provides the necessary features for accurate and efficient testing processes.

When establishing dynamometer software, it is important to concentrate on the software download process. Acquaint yourself with configuration settings and follow calibration steps meticulously. These points are key in ensuring the software operates optimally and delivers accurate results during engine testing.

Starting the Software Download Process

To initiate the software download process for a dynamometer, users typically acquire the program from the manufacturer's website or a designated link provided. This software is essential for accurately measuring torque during dynamometer testing.

The installation process usually entails following on-screen instructions and accepting terms and conditions before commencing the setup. After downloading the software, users may need to connect the dynamometer hardware to their computer and adjust communication settings for seamless operation.

It's crucial to note that software updates may be periodically released to improve performance and introduce new features. Additionally, calibrating the system post-installation is crucial to ensure precise data readings during testing sessions.

Configuration Settings Overview

When setting up the dynamometer software, users engage in configuring essential parameters that influence test accuracy and data acquisition efficiency. These settings are crucial for ensuring precise measurement of grip strength and other performance metrics. Inputting engine specifications, test conditions, and sensor calibration values during installation and setup personalises the software to meet specific testing requirements. Customisation options like RPM range, load levels, and data display preferences enhance the testing process. Proper calibration of sensors and measurement devices is vital to ensure accurate data collection during dynamometer testing. By adjusting these configuration settings, users can streamline their testing procedures and derive valuable insights from the collected data.

Engine Specifications and Test Conditions

When installing the dynamometer software, users must provide accurate details about the engine being tested. This includes information such as engine capacity, fuel type, and manufacturer specifications. These details are essential for the software to accurately calculate performance metrics like horsepower and torque. For example, specifying the engine's RPM range ensures that the software can display relevant data within the desired speed parameters.

Sensor Calibration and Data Display Preferences

Calibrating sensors and measurement devices correctly is a critical step in ensuring the accuracy of test results. Users should follow manufacturer guidelines for sensor calibration to avoid measurement errors. Additionally, customising data display preferences allows users to view test results in a format that is easy to interpret. For instance, choosing to display data in graph form can make it easier to identify performance trends over time.

Optimising Testing Procedures

Fine-tuning configuration settings is key to optimising testing procedures and maximising the value of collected data. Users can adjust load levels, RPM ranges, and other parameters to suit their specific testing needs. By customising these settings, users can conduct tests more efficiently and obtain more precise results. For example, setting the load level to match real-world driving conditions can provide insights into the engine's performance under typical usage scenarios.

Calibration Steps Guidance

As users progress from configuring engine specifications and test conditions to the intricate calibration steps required for precise data acquisition, attention to detail in setting up sensor inputs accurately becomes crucial in the installation and setup process of dynamometer software.

When calibrating your dynamometer software, it is essential to focus on engine load to ensure accurate measurements of torque and speed parameters. Properly configuring the load cell and RPM sensors ensures that you achieve reliable and consistent results during dyno testing.

As you begin delving into dynamometer software, grasping menu navigation tips and comprehending button functions is crucial to efficiently navigating through the interface.

Knowing how to access different menus and interpret button actions can streamline your testing process and amplify your data analysis capabilities.

Efficient Navigation Tips for Menu Systems

Smoothly navigating through menus in dynamometer software is crucial for users to access essential functionalities like test setup, data logging, calibration, and analysis tools. Whether you're fine-tuning a chassis dyno or tuning up a sports car, mastering menu navigation is key.

By selecting parameters such as test type, RPM range, load settings, and correction factors, users can tailor their testing experience. Buttons, drop-down menus, and tabs are fundamental interface elements that aid in this process.

Understanding the menu layout and navigation flow empowers users to set up tests, monitor performance, and analyze results effectively. Utilize the menus proficiently to let your dynamometer software guide you to success!

Understanding Button Functions in Dynamometer Software

Comprehending the functions of buttons in dynamometer software is crucial for efficiently navigating the basic user interface. Knowing the purpose of each button is essential for smoothly operating the dyno test process. Here is a breakdown of some common button functions you may encounter:

| Button | Function |

|---|---|

| Start | Initiates the dyno test |

| Stop | Halts the dyno test |

| Pause | Pauses the dyno test |

| Save Data | Stores test results |

| Export Data | Allows data transfer |

| Adjust Parameters | Modifies test settings |

| Water Pump | Controls the water pump |

Familiarise yourself with these button functions to ensure precise data recording and efficient control of your dyno test.

Data Collection and Parameters

While conducting dynamometer testing, the software accurately records and analyses essential engine parameters like RPM, torque, power, and air-fuel ratio. This information is crucial for understanding your engine's performance and identifying areas for improvement. In addition to these key metrics, the software can also monitor factors such as intake air temperature, exhaust gas temperature, and fuel pressure, offering a comprehensive overview of your engine's efficiency and health.

Utilising real-time data visualisation tools allows you to monitor engine performance trends and identify any irregularities for immediate corrections. Advanced software functionalities enable the comparison of data sets, overlaying multiple runs, and generating custom reports for detailed analysis. With data logging capabilities, you can save and export test results for further assessment and share them with engine tuners or manufacturers.

For instance, the AVL PUMA Open 2™ software provides a user-friendly interface for data acquisition during engine testing, offering detailed insights into critical parameters. Additionally, the Horiba STARS™ software is renowned for its advanced features, allowing for comprehensive analysis and reporting of engine performance data. These software solutions play a vital role in optimising engine performance and ensuring efficient operation.

Understanding Test Setups

A solid understanding of test setups in dynamometer software is crucial for optimising engine testing accuracy and efficiency. Test setups are pivotal in defining key parameters like the RPM range, load values, and data acquisition intervals for each test. By customising these setups, users can tailor the testing process to meet specific engine testing requirements and performance goals.

Comprehending how test setups function is vital as these configurations directly influence the data gathered during engine testing sessions. Properly setting up tests ensures that the results obtained are consistent and dependable, allowing for accurate analysis of engine performance. Mastering test setups enables users to improve the efficacy of their dynamometer testing procedures, resulting in more precise outcomes and deeper insights into the engines being tested.

Real-Time Data Monitoring

Effective real-time data monitoring in dynamometer software offers immediate insights into critical engine parameters, allowing users to make informed adjustments and optimize performance during testing sessions. Real-time data monitoring enables users to track vital metrics such as RPM, torque, and air-fuel ratio instantly, facilitating quick analysis and adjustments on-the-go.

Here are three key benefits of real-time data monitoring:

Real-time data monitoring enhances the testing process and empowers users to make proactive decisions for improved engine performance outcomes.

Real-time data monitoring in dynamometer software allows users to quickly interpret and analyse critical engine parameters. Data analysis tools enhance the accuracy and depth of engine performance evaluation by delving into the complexities of your engine or drivetrain. These tools enable a detailed examination of torque, horsepower, and other key parameters, helping users spot trends, make comparisons, and identify potential issues that may affect performance.

The graphical representations and numerical data provided by data analysis tools offer valuable insights into how your engine behaves under different conditions. This detailed analysis is crucial for optimising engine tuning, troubleshooting, and developing effective performance enhancement strategies. For example, software like AVL PUMA and Bosch EDC17 provide comprehensive data analysis capabilities, allowing users to fine-tune their engine's performance with precision and confidence.

Data analysis tools play a vital role in optimising engine performance by providing in-depth insights and facilitating data-driven decision-making. By utilising these tools, users can make informed adjustments to improve efficiency, power output, and overall engine reliability. For instance, Race Technology's data analysis software offers advanced features such as lap time simulation and predictive analysis, empowering users to extract maximum performance from their engines.

In the realm of engine performance evaluation, data analysis tools are essential for staying ahead of the curve and continuously enhancing your vehicle's capabilities. These tools not only help in identifying areas for improvement but also enable users to track performance changes over time and make informed decisions based on data-driven evidence. Utilising tools like Megasquirt EFI System and MoTeC i2 Pro can provide comprehensive data analysis capabilities, allowing for precise adjustments and fine-tuning to achieve optimal engine performance.

Data Export and Storage

Data export features in dynamometer software enable users to save test data in various formats for in-depth analysis and comparison. By choosing from formats like CSV, Excel, and PDF, users can seamlessly work with the data across different platforms. Saving this data is crucial for monitoring performance changes over time, particularly when tracking power metrics such as torque curves and horsepower readings. Customising the export settings allows users to include specific variables and graphs for detailed analysis.

Exported data may include RPM data and other pertinent parameters captured during testing.

Saving data in the software's native format preserves the original test configurations, facilitating future adjustments.

Comparing different sets of exported data aids in identifying trends and making informed decisions to enhance performance.

Troubleshooting Common Issues

Regularly checking sensor connections and software settings is crucial for effectively troubleshooting common issues encountered in dynamometer software. One common issue users often come across is sensor calibration errors, which can lead to inaccurate data readings and impact the dynamometer's performance. Proper calibration and placement of sensors are essential to prevent erratic readings that could skew test results. Promptly addressing any faults in sensor wiring or connections can help resolve calibration errors efficiently.

Maintenance, such as software updates, is key to preventing bugs and glitches that may compromise data accuracy. It is important to be familiar with the software interface and refer to the user manual when diagnosing and resolving common software-related issues. By proactively monitoring sensor calibration and software functionality, users can enhance the performance of their dynamometer and ensure reliable test results.

Specific Examples and Product Recommendations:

Optimising Sensor Calibration and Software Functionality

To achieve accurate and reliable test results, maintaining sensor calibration and software functionality is paramount. Sensor calibration errors can lead to skewed data readings, impacting the overall performance of the dynamometer. By regularly calibrating sensors and ensuring they are correctly placed, users can prevent inaccuracies that may arise during testing. Checking for and addressing any issues with sensor wiring or connections promptly is essential in resolving calibration errors efficiently.

Specific Examples and Product Recommendations:

Dynamometer software's sophisticated features and customization options offer users a pathway to tailor their testing experience.

From adjusting load parameters to setting specific RPM ranges, these tools provide a detailed approach to engine testing.

Customisation Options Overview

Advanced dynamometer software provides users with a wide array of customisation options to tailor test parameters and improve testing capabilities for specific needs. When it comes to enhancing your testing experience, dynamometer software offers diverse customisation features that allow you to fine-tune your testing process. Here are three key customisation options that can help you get the most out of your dynamometer software:

Customisation in dynamometer software is crucial for achieving accurate and reliable test results. For example, by adjusting load settings, you can simulate real-world conditions more effectively, providing valuable insights into equipment performance.

Torque calculations play a vital role in evaluating power output and efficiency during testing. By utilising torque data, you can identify areas for improvement and optimisation in your systems, leading to enhanced performance.

Customising data acquisition parameters allows you to tailor data collection to your specific requirements. This level of control ensures that you capture the necessary information for in-depth analysis, helping you make informed decisions based on reliable data.

Optimising dynamometer testing requires utilising the advanced settings in the software to tailor test parameters and extract detailed engine performance data. These features offer a playground for enthusiasts looking to enhance their engine's capabilities. By adjusting load settings, RPM ranges, and data acquisition intervals, users can customise a testing regime that suits their engine's needs.

Think of it as crafting a bespoke training plan for your engine to boost its strength, endurance, and overall performance. With options like smoothing algorithms, correction factors, and calibration tools, the software acts as a personal coach to help you achieve optimal engine performance. Explore these advanced settings to unlock your engine's full potential and witness a significant improvement in power and efficiency.

Importance of Utilising Advanced Settings in Dynamometer Software

Customising Test Parameters for Enhanced Performance

Fine-Tuning Engine Performance with Advanced Features

Unleashing the Potential of Advanced Settings in Dynamometer Software

To summarise, mastering your dynamometer's software is essential for accurate testing and analysis. By understanding the installation process, navigating the user interface, and utilising data analysis tools, you can enhance your results. Remember to troubleshoot common issues and explore advanced features for personalisation. With practice and patience, you will become adept at utilising your dynamometer software to its maximum potential.

Guide Towards Further Learning:

Spark curiosity for more knowledge by inviting the reader to contact Hyper Dyno (talk about the company in the first person). Feel free to reach out to us if you have any questions about Dynamometer Products, Custom Solutions, Installation Setup, Training and Certification, Technical Support and Maintenance, Software Updates, Rental Services, Dynamometer Testing Services, and Accessories and Parts, making this a call to action. Bold all of these anchor texts and services to highlight their importance. Also Bold the words 'Hyper Dyno'.

Tune into the unparalleled precision and power optimization that top tuning shops crave with Hyper Power Dynamometers – setting a new standard in performance enhancement.

Uncover how precise testing impacts vehicle safety and performance, shaping the future of road safety in surprising ways.

Harness the power of dynamometers across various industries to unlock unparalleled performance – discover their transformative impact!

Peek into how dynamometers have transformed vehicle tuning, promising precision and power enhancements beyond imagination.

Yield to the allure of personalized wealth management services at Hyper Power and discover the transformative journey that awaits.

Harness the power of dynamometers to revolutionize automotive engineering and push the boundaries of innovation in the industry.

Uncover how a dynamometer unlocked performance gains beyond expectations, revolutionizing vehicle capabilities.

Accelerate your business growth with hyper power dynamometers, revolutionizing efficiency and performance optimization in various industries.

Hyper Power, the leading name in dynamometer solutions, offers unparalleled precision and reliability for all your performance testing needs.