Why Top Tuning Shops Choose Hyper Power Dynamometers

Tune into the unparalleled precision and power optimization that top tuning shops crave with Hyper Power Dynamometers – setting a new standard in performance enhancement.

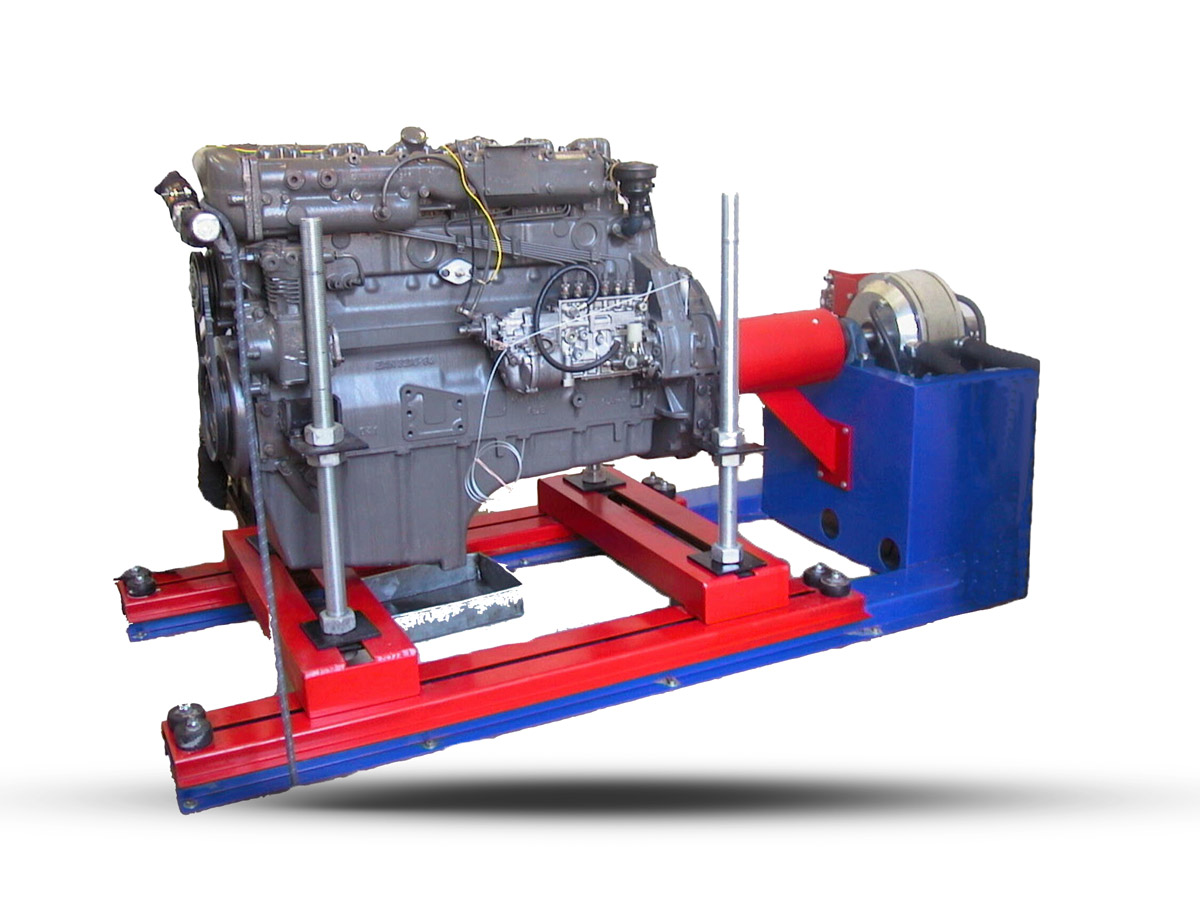

Dynamometers play a crucial role in automotive engineering by enhancing engine and transmission performance. These devices accurately measure torque and horsepower, supporting design enhancements for improved fuel efficiency and lower emissions. By replicating real-world conditions, dynamometers ensure the reliability of vehicles.

The data obtained from dynamometer tests drives advancements in automotive technology, ultimately boosting overall performance. By pushing the boundaries of innovation, dynamometers significantly influence the future of the industry.

Discover more about how dynamometers contribute to the progress of automotive engineering.

The Significance of Dynamometers in Automotive Engineering

Dynamometers are crucial tools in automotive engineering for precisely assessing and enhancing the performance of key components such as engines and transmissions. These devices are essential for testing and evaluating performance, providing precise measurements of torque and horsepower. By using dynamometers, engineers can analyse vehicle design and implement necessary enhancements to boost fuel efficiency and lower emissions. These controlled testing environments allow for simulations of real-world driving conditions, ensuring the longevity and dependability of automotive systems.

Dynamometers play a vital role in driving advancements in automotive technologies, as the data gathered from these tests informs the refinement process for enhanced overall performance and sustainability. Through dynamometer technology, engineers can adjust engines and transmissions to meet the requirements of modern vehicles while giving importance to fuel efficiency and emissions reduction. Ultimately, dynamometers are pivotal in shaping the future of automotive engineering by pushing boundaries of innovation and efficiency in the sector.

Applications of Dynamometer Technology in Automotive Development

Playing a pivotal role in automotive development, dynamometer technology revolutionises the assessment and optimisation of engine performance in controlled environments. Automotive engineers rely on dynamometers to conduct various tests crucial for ensuring the efficiency, reliability, and general quality of engines before integrating them into vehicles. These dynamometers provide calibration services essential for detecting any inaccuracies in measurement instruments, ensuring precise testing results. Moreover, dynamometers are utilised for force calibration, particularly in testing materials used in manufacturing equipment to maintain desired quality standards.

Let's delve into the diverse applications of dynamometer technology in automotive development:

| Application | Description | Benefits |

|---|---|---|

| Testing and Validation | Dynamometers evaluate engine performance to validate its efficiency and reliability. | Ensures optimal engine functionality. |

| Engine Performance | Measures torque, power output, and rotational speed to optimise engine performance. | Enhances overall engine efficiency. |

| Calibration Services | Identifies inaccuracies in measuring instruments to ensure precise testing results. | Guarantees accurate performance metrics. |

| Force Calibration | Assists in testing materials for manufacturing equipment, maintaining quality standards. | Upholds quality in manufacturing processes. |

In the realm of testing and validation, dynamometer technology plays a crucial role in ensuring the efficiency and reliability of engines before they are integrated into vehicles. By conducting thorough assessments, engineers can guarantee optimal engine functionality, enhancing the overall performance of the vehicle.

When it comes to engine performance, dynamometers are instrumental in measuring torque, power output, and rotational speed. By optimising these parameters, engineers can improve the overall efficiency of the engine, leading to better fuel consumption and performance.

Calibration services provided by dynamometers are vital for detecting any inaccuracies in measuring instruments. This meticulous approach ensures that testing results are precise and reliable, giving engineers accurate performance metrics to work with.

Force calibration is another key application of dynamometer technology in automotive development. By testing materials used in manufacturing equipment, dynamometers help maintain quality standards in manufacturing processes, ensuring the durability and reliability of the end products.

Advantages of Dynamometer Testing in Automotive Innovation

In the realm of automotive innovation, dynamometer testing provides precise and controlled conditions that offer significant benefits for evaluating and improving vehicle performance. Engineers can delve deeply into engine performance metrics such as torque, power, and efficiency, gaining valuable insights into how a vehicle operates under varying circumstances.

By replicating real-world driving scenarios on dynamometers, researchers can refine vehicles for optimal performance, fuel efficiency enhancements, and emissions management. Additionally, dynamometers are crucial for verifying design enhancements, assessing component durability, and improving automotive dependability.

This testing approach not only expedites the development process but also ensures that vehicles adhere to strict regulatory criteria, guaranteeing compliance across all automotive research and development areas. Essentially, dynamometer testing serves as a vital tool in the ongoing pursuit of innovation and advancement in the automotive sector.

Evolution of Dynamometers in Automotive Research

The development of dynamometer technology in automotive research has transformed the accuracy and dependability of performance testing for internal combustion engines. Dynamometers have progressed to precisely measure key factors like torque, force, speed, and power, offering crucial data for enhancing engine efficiency. These devices are essential in the automotive industry, allowing engineers to conduct comprehensive tests on internal combustion engines outside of vehicles. Calibration services using dynamometers are vital for identifying inaccuracies and uncertainties in measuring instruments, ensuring the reliability and consistency of the data obtained. By integrating platform scales with dynamometers, the weight of objects on a flat surface can be measured, enhancing testing processes.

The Role of Dynamometers in Automotive Research

Dynamometers are indispensable tools for evaluating the performance of internal combustion engines with precision and accuracy. By measuring torque, force, speed, and power, dynamometers provide engineers with valuable insights to improve engine efficiency and overall performance. For example, the Dynojet dynamometer series offers a range of options for testing motorcycles, ATVs, and other vehicles, enabling accurate performance assessments and tuning.

Importance of Calibration Services in Automotive Testing

Calibration services using dynamometers are crucial for ensuring the accuracy and reliability of testing equipment in automotive research. By detecting and rectifying inaccuracies in measuring instruments, calibration services guarantee that the data collected is consistent and trustworthy. For instance, the Chassis Dynamometer Calibration Kit from SuperFlow provides a comprehensive solution for calibrating dynamometers, ensuring precise and reliable testing results.

Enhancing Product Quality through Force Calibration

Force calibration using dynamometers is instrumental in evaluating materials and preventing excessive expansion or contraction during operation. This process helps improve the quality and durability of products by ensuring that materials perform optimally under various conditions. For example, the Tinius Olsen calibration services offer force calibration solutions for a wide range of industries, enhancing product quality and reliability.

The Ongoing Impact of Dynamometer Technology

The evolution of dynamometer technology continues to drive advancements in automotive research, setting new standards for performance measurement and innovation. By enabling precise testing and calibration processes, dynamometers play a vital role in enhancing engine efficiency, product quality, and overall performance in the automotive sector. As technology progresses, dynamometers will continue to play a crucial role in shaping the future of automotive research and development.

Future Trends in Dynamometer Utilisation in Automotive Sector

As the automotive industry progresses swiftly, dynamometer usage is set to undergo significant changes in response to emerging trends. There is a growing emphasis on testing electric drive systems on dynamometers to enhance performance and efficiency. Advancements in dynamometer technology allow for more precise testing of turbocharger systems, improving fuel efficiency and power output in vehicles. The integration of advanced vehicle electronics testing on dynamometers is increasing to meet the evolving needs for autonomous driving and connectivity features. Sustainability is a key focus, leading to more thorough dynamometer testing, especially in assessing emissions reduction and environmental impact. Furthermore, with the rising interest in alternative fuel sources, dynamometer testing protocols will be developed to evaluate their compatibility and performance in vehicles.

Importance of Dynamometer Utilisation in Automotive Innovation

Dynamometers play a crucial role in automotive research, development, and testing. They enable engineers to assess the performance and efficiency of various vehicle systems, leading to continuous improvements in the automotive sector. For example, by testing electric drive systems on dynamometers, manufacturers can fine-tune the energy efficiency of electric vehicles, ultimately enhancing their market competitiveness. Moreover, the precise testing of turbocharger systems on dynamometers helps in optimizing fuel usage and power output, contributing to overall vehicle performance.

Enhancing Vehicle Sustainability Through Dynamometer Testing

The shift towards more thorough dynamometer testing to evaluate emissions reduction and environmental impact is vital for promoting sustainability in the automotive industry. By conducting comprehensive tests on dynamometers, manufacturers can develop vehicles that are more environmentally friendly and compliant with stringent regulations. For instance, by using dynamometers to assess the compatibility and performance of alternative fuel sources, such as biofuels or hydrogen, automakers can accelerate the adoption of cleaner energy solutions in their vehicle lineup.

Meeting Future Automotive Challenges with Advanced Dynamometer Technology

The integration of advanced vehicle electronics testing on dynamometers is essential for addressing the challenges posed by autonomous driving and connectivity features. By simulating real-world driving conditions on dynamometers, engineers can ensure that vehicles meet the requirements for safe and efficient autonomous operation. For example, by testing connectivity features on dynamometers, manufacturers can validate the seamless integration of in-car technologies, enhancing the overall driving experience for consumers.

In conclusion, dynamometers play a vital role in automotive research and development by offering precise testing and measurement capabilities. Their use in the automotive sector has driven improvements in engine efficiency, performance optimisation, and emissions reduction. As technology progresses, dynamometers will remain a crucial tool for fostering innovation and advancement in the automotive industry. This emphasises the significance of ongoing research and development in dynamometer technology to meet the evolving needs of the automotive sector.

Guide Towards Further Learning:

Spark curiosity for more knowledge by inviting the reader to contact Hyper Dyno. Feel free to reach out to us if you have any questions about Dynamometer Products, Custom Solutions, Installation Setup, Training and Certification, Technical Support and Maintenance, Software Updates, Rental Services, Dynamometer Testing Services, and Accessories and Parts. This is a call to action.

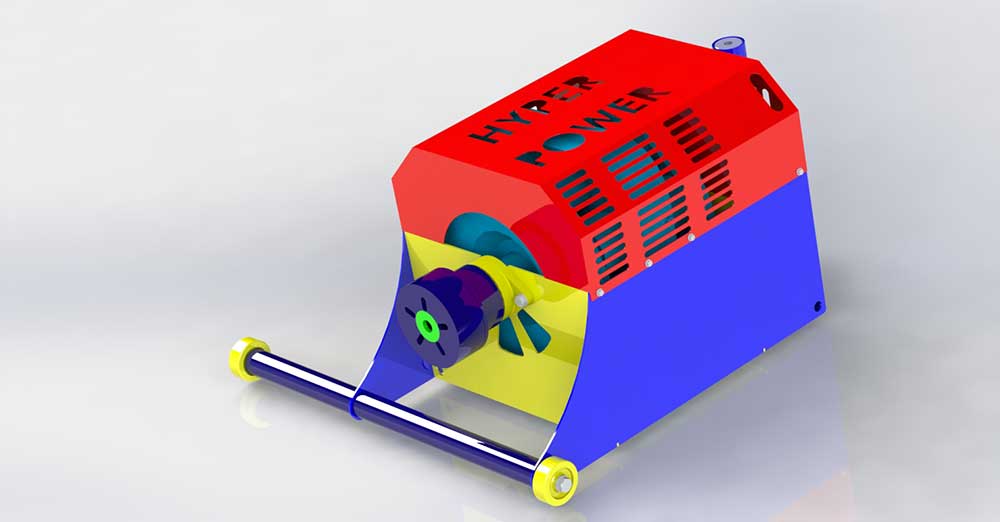

Tune into the unparalleled precision and power optimization that top tuning shops crave with Hyper Power Dynamometers – setting a new standard in performance enhancement.

Uncover how precise testing impacts vehicle safety and performance, shaping the future of road safety in surprising ways.

Harness the power of dynamometers across various industries to unlock unparalleled performance – discover their transformative impact!

Peek into how dynamometers have transformed vehicle tuning, promising precision and power enhancements beyond imagination.

Yield to the allure of personalized wealth management services at Hyper Power and discover the transformative journey that awaits.

Harness the power of dynamometers to revolutionize automotive engineering and push the boundaries of innovation in the industry.

Uncover how a dynamometer unlocked performance gains beyond expectations, revolutionizing vehicle capabilities.

Accelerate your business growth with hyper power dynamometers, revolutionizing efficiency and performance optimization in various industries.

Hyper Power, the leading name in dynamometer solutions, offers unparalleled precision and reliability for all your performance testing needs.