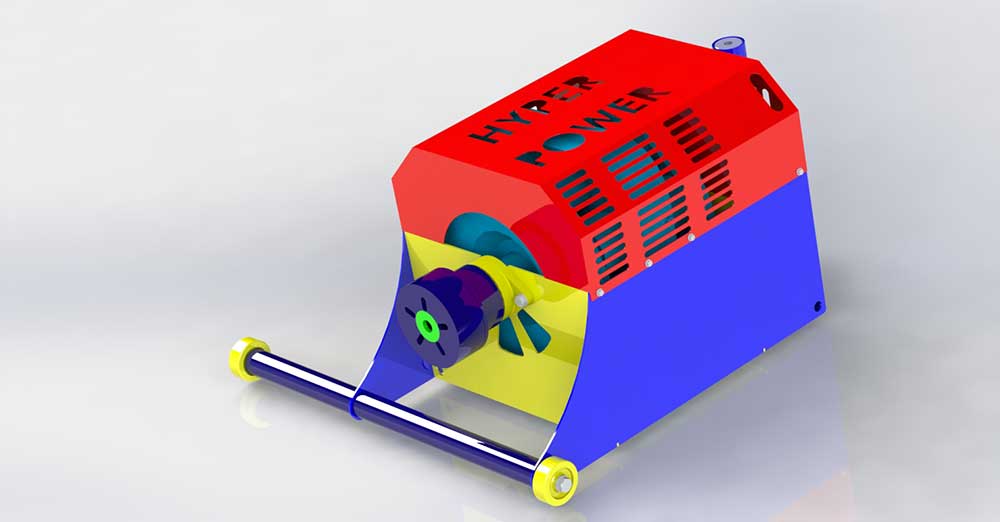

Why Top Tuning Shops Choose Hyper Power Dynamometers

Tune into the unparalleled precision and power optimization that top tuning shops crave with Hyper Power Dynamometers – setting a new standard in performance enhancement.

Leading tuning workshops prefer Hyper Power Dynamometers for their unmatched precision, optimisation of power, and reliable performance enhancements. The advanced predictive software allows for precise tuning adjustments, providing a visual representation of their impact on engine performance. This tool empowers tuners to make well-informed decisions that result in significant improvements in engine power and efficiency.

With Hyper Power Dynamometers, adjustments are streamlined, simplifying the process of enhancing engine parameters effectively while maintaining a high level of accuracy. They offer a competitive advantage in power curve optimisation, meeting the specific requirements of top tuning workshops. Discover how these dynamometers are transforming the tuning process with their cutting-edge technology and performance-driven approach.

Hyper Power Dynamometers’ high-precision data acquisition software represents a pinnacle of technological advancement in analysing engine performance. This state-of-the-art software offers tuning workshops detailed insights into crucial engine metrics, such as power output, torque figures, and overall efficiency.

The real-time monitoring capabilities of this software enable continuous tracking of vital parameters like air-fuel ratio and exhaust gas temperatures, ensuring peak engine performance. Additionally, the software facilitates the implementation of customised tuning strategies based on the extensive data gathered during testing sessions.

Real-time monitoring is essential for tuning shops as it allows them to instantly track and analyse critical engine parameters. By continuously monitoring metrics like air-fuel ratio and exhaust gas temperatures, tuning shops can make immediate adjustments to optimise engine performance.

For instance, if the air-fuel ratio deviates from the ideal range, the tuning shop can quickly adjust the fuel injection to ensure efficient combustion and maximum power output.

The ability to implement customised tuning strategies is a key feature of Hyper Power Dynamometers’ data acquisition software. By analysing the data collected during testing sessions, tuning shops can develop precise tuning strategies tailored to the specific needs of each engine.

For example, if the software detects a power output dip at a certain RPM range, tuning shops can adjust the fuel and ignition timing to optimise performance in that specific range.

Hyper Power Dynamometers’ precision data acquisition software not only enhances engine performance but also boosts efficiency and productivity in tuning workshops.

By providing detailed insights into engine metrics and facilitating real-time monitoring, the software streamlines the tuning process, allowing workshops to work more efficiently. This efficiency translates into faster turnaround times for tuning projects, ultimately increasing the workshop’s productivity and profitability.

Hyper Power Dynamometers offer state-of-the-art engine software that enables precise performance analysis and boosts tuning capabilities.

With advanced load control technology, these dynamometers allow for real-time adjustments to optimise power output efficiently.

Tuning shops choose Hyper Power Dynamometers for their ability to provide customisable test profiles and reliable, consistent performance.

Cutting-Edge Engine Software

Highly advanced engine software plays a crucial role in achieving precise engine optimisation for top tuning shops utilising Hyper Power Dynamometers. This state-of-the-art software acts as the central intelligence, allowing tuners to make intricate adjustments to enhance performance.

Picture having a virtual assistant providing real-time engine performance data during dyno testing, assisting in refining fuel and ignition parameters for optimal power output. Equipped with features like a pressure sensor, this software enhances efficiency and power gains, giving tuning shops the competitive advantage they need to excel.

It serves as the key tool that elevates a decent tune to an exceptional one, establishing Hyper Power Dynamometers as the preferred choice for leading tuning shops.

Utilising state-of-the-art technology for engine optimisation, Precision Performance Analysis plays a vital role in achieving peak efficiency with Hyper Power Dynamometers. A crucial element enhancing this analysis is the load cell, which precisely measures the engine’s performance.

This data is then inputted into advanced simulation software, allowing for accurate tuning adjustments to maximise power output. The incorporation of O2 sensors on each header pipe offers detailed insights into fuel distribution, assisting in fine-tuning the engine for optimal operation. Additionally, predictive programmes aid in anticipating airflow patterns, empowering operators to make proactive adjustments for enhanced engine efficiency.

Hyper Power Dynamometers stand out in providing the necessary tools for meticulous performance analysis, making them a top choice for tuning shops striving for excellence.

| Load Cell | Advanced Simulation Software |

|---|---|

| Accurate measurement of engine performance | Precise tuning adjustments for maximum power output |

| Insights into fuel distribution | Fine-tuning engine for optimal operation |

| Proactive airflow pattern adjustments | Tools for meticulous performance analysis |

The latest technology in engine optimisation has revolutionised tuning capabilities, allowing for unparalleled precision in adjusting fuel and ignition parameters.

Hyper Power Dynamometers provide advanced load control, enabling precise adjustments. These dynamometers utilise cutting-edge software for instant data analysis, empowering tuners to optimise settings quickly. The advanced tuning features on Hyper Power Dynamometers allow for precise adjustments to fuel and ignition parameters, ensuring the engine operates at its best in various driving conditions.

Top tuning shops prefer Hyper Power Dynamometers for their reliability and consistency in delivering optimised tuning solutions. With dynamic testing scenarios that replicate real-world driving conditions, these dynamometers enable tuners to achieve outstanding results.

The use of advanced technology in engine tuning is crucial for achieving peak performance. By having the ability to make precise adjustments to fuel and ignition parameters, tuners can ensure that the engine operates efficiently in diverse driving situations.

Hyper Power Dynamometers stand out for their reliability and consistency in providing optimised tuning solutions. Tuners can rely on these dynamometers to deliver exceptional results due to their accurate load control and real-time data analysis capabilities. In the competitive world of tuning, having access to top-notch equipment like Hyper Power Dynamometers can make a significant difference in achieving superior engine performance.

One of the key features of Hyper Power Dynamometers is their real-time data analysis capability. This technology allows tuners to instantly analyse engine performance data and make immediate adjustments to optimise settings.

By having access to this level of detailed information in real-time, tuners can fine-tune fuel and ignition parameters with precision, ensuring the engine operates at its peak efficiency. This feature is essential for achieving optimal performance in various driving conditions and is a game-changer for tuning shops striving for excellence.

Hyper Power Dynamometers incorporate cutting-edge predictive programs that revolutionise airflow analysis. These programs offer insights into air intake, fuel distribution, and exhaust flow dynamics. They play a pivotal role in fine-tuning engine performance by enabling adjustments to parameters such as fuel mixture and airflow.

Airflow Simulation Advantages

By using predictive software to analyse airflow patterns, top tuning shops can maximise the benefits of airflow simulation to enhance engine performance. These advanced tools enable shops to anticipate power improvements, enhance engine efficiency, and adjust fuel distribution for optimal combustion.

This predictive airflow analysis helps in fine-tuning header collectors for peak performance and ensures that safety systems are optimised to manage the increased power output effectively. The simulation advantages empower top tuning shops to achieve precise tuning, improve engine output, and deliver exceptional performance to customers.

With airflow simulation, these shops can lead the way in fine-tuning every aspect of the engine to unlock its full potential and provide an exciting driving experience.

By utilising advanced predictive software for airflow analysis, tuning workshops can achieve outstanding precision in engine performance tuning. These programs offer tuners detailed insights into the airflow within the engine, enabling them to optimise fuel distribution and combustion processes effectively.

This optimisation results in increased power output and improved overall engine efficiency. Tuners can adjust various engine parameters with accuracy based on the predictions provided by these programs, ensuring precise modifications.

The use of predictive software not only enhances performance but also ensures that tuning workshops attain the highest level of accuracy in refining engine enhancements. With this technology, top tuning workshops can deliver exceptional results to their clients confidently.

Predictive programs play a crucial role in the tuning process by providing tuners with valuable information on airflow dynamics. By accurately predicting how air moves through the engine, these programs enable tuners to make informed decisions when adjusting engine parameters.

This level of precision is essential for achieving optimal performance and efficiency in engine tuning. For example, software such as Dynojet Power Vision CX offers real-time data and predictive tuning capabilities, allowing tuners to make immediate adjustments for maximum results.

The use of predictive programs not only benefits tuning shops in achieving accuracy but also enhances customer satisfaction. By making precise adjustments based on airflow analysis, tuners can deliver customised tuning solutions that meet the specific requirements of each client.

This tailored approach ensures that customers receive the best possible performance enhancements for their engines. For instance, APR’s ECU Upgrade optimises fuel and timing maps based on airflow data, providing customers with a tailored tuning solution that maximises performance and efficiency.

Predictive programs are essential tools in enhancing engine performance by analysing airflow. These programs act as a crystal ball for tuning shops, offering insights into your engine’s future performance. By precisely analysing airflow, tuning experts can access crucial data to fine-tune engines for optimal power output.

These programs provide detailed insights into fuel distribution by simulating O2 sensors on each header pipe.

This information is vital for improving combustion efficiency and overall engine performance. With the ability to adjust header collectors based on software predictions, tuning shops can maximise the efficiency of engines.

Advanced data acquisition software expedites testing procedures, streamlining the tuning process. This acceleration leads to smoother operations and quicker delivery of optimal results. With the right software tools, tuning shops can achieve precision tuning in record time.

Specific Examples and Product Recommendations:

Improved Engine Performance Tuning with Simulation

Enhancing engine performance tuning with simulation software offered by Hyper Power Dynamometers transforms the way tuning shops optimise engines. By utilising state-of-the-art predictive programs that analyse airflow and O2 sensors on each header pipe, tuning for forced induction vehicles becomes a precise and meticulous process.

This simulation software not only provides accurate data but also forecasts how adjustments will impact performance, streamlining tuning sessions and conserving resources. Picture having a digital assistant that can predict how alterations in fuel distribution will influence your engine’s power output – that’s the capability of Hyper Power Dynamometers’ simulation software.

It’s akin to possessing a crystal ball for your vehicle, enabling you to fine-tune with confidence and precision. With this technology available, top tuning shops can elevate their tuning practices to new levels, ensuring that every enhancement brings them nearer to perfection.

The significance of simulation software in engine tuning cannot be overstated. It allows tuning shops to make informed decisions based on accurate predictions, saving time and resources in the process. For example, Hyper Power Dynamometers’ simulation software can forecast the impact of adjusting fuel distribution on engine power output, enabling tuners to make precise changes for optimal performance.

This level of insight is invaluable for fine-tuning engines to achieve peak efficiency and power delivery. By leveraging simulation software, tuning shops can stay ahead of the competition and deliver exceptional results to their clients.

Hyper Power Dynamometers’ simulation software stands out as a top recommendation for tuning shops seeking to enhance their engine performance tuning processes. This software offers advanced predictive capabilities, allowing tuners to analyse airflow and O2 sensor data with precision.

By visualising how adjustments will affect performance, tuners can make informed decisions that lead to significant improvements in engine power and efficiency. With Hyper Power Dynamometers’ simulation software, tuning shops can take their tuning game to the next level, achieving unparalleled results and customer satisfaction.

Efficiency in adjustments and enhancements is crucial for tuning workshops aiming to fine-tune engine performance with accuracy and speed. Hyper Power Dynamometers stand out in this area, offering a range of advantages that cater to the requirements of top tuning workshops:

Utilising tools like the Hyper Power Dynamometers can significantly boost the performance of engines by providing the necessary precision and speed for adjustments. These dynamometers are essential for achieving optimal results in tuning workshops seeking to enhance engine performance efficiently.

In the quest for a competitive edge in optimising power curves, leading tuning workshops rely on the precision and dependability of Hyper Power Dynamometers. These state-of-the-art tools offer the ability to fine-tune power delivery with precision, ensuring that each adjustment is tailored for optimal performance. By harnessing the capabilities of Hyper Power Dynamometers, tuning workshops can meticulously map out power curves, allowing them to customise the engine’s output to perfection.

When it comes to optimising power curves, hitting the mark at full throttle is crucial. Hyper Power Dynamometers excel in this aspect, providing precise torque optimisation that results in enhanced power curves. The competitive advantage gained through accurate power curve mapping can be pivotal in achieving top-tier engine performance.

In the realm of tuning, consistency is paramount. Hyper Power Dynamometers give tuning workshops the assurance of consistent and reliable outcomes, guaranteeing that each adjustment brings them closer to the ideal power curve. By utilising the capabilities of Hyper Power Dynamometers, tuning workshops can stay ahead of the competition and surpass expectations.

In summary, hyper power dynamometers provide top tuning shops with the precision, advanced technology, predictive programmes, accelerated tuning process, efficiency, and competitive edge required for optimal engine optimisation. By utilising these tools, tuning shops can enhance performance, optimise power output, and stay ahead of the competition in the automotive tuning industry.

If you want to learn more about our Dynamometer Products, Custom Solutions, Installation Setup, Training and Certification, Technical Support and Maintenance, Software Updates, Rental Services, Dynamometer Testing Services, and Accessories and Parts, feel free to contact Hyper Dyno. We are here to answer any questions you may have and provide you with the support you need.

Tune into the unparalleled precision and power optimization that top tuning shops crave with Hyper Power Dynamometers – setting a new standard in performance enhancement.

Uncover how precise testing impacts vehicle safety and performance, shaping the future of road safety in surprising ways.

Harness the power of dynamometers across various industries to unlock unparalleled performance – discover their transformative impact!

Peek into how dynamometers have transformed vehicle tuning, promising precision and power enhancements beyond imagination.

Yield to the allure of personalized wealth management services at Hyper Power and discover the transformative journey that awaits.

Harness the power of dynamometers to revolutionize automotive engineering and push the boundaries of innovation in the industry.

Uncover how a dynamometer unlocked performance gains beyond expectations, revolutionizing vehicle capabilities.

Accelerate your business growth with hyper power dynamometers, revolutionizing efficiency and performance optimization in various industries.

Hyper Power, the leading name in dynamometer solutions, offers unparalleled precision and reliability for all your performance testing needs.