Hydraulic Dynos: Applications in Heavy Industry Jobs

Hydraulic dynos prevent catastrophic field failures—but most heavy industry operators still skip this critical step. Learn why.

The safe and proper use of a dynamometer requires adherence to established safety protocols and best practices throughout the entire testing process.

Pre-operational safety checks are essential, including visual inspections and proper securing of the test object. Additionally, personnel must wear personal protective equipment such as safety glasses and gloves.

Regular dynamometer maintenance, calibration, and inspection are vital to ensure accurate results.

Safe testing procedures and emergency response planning are also crucial. Clear communication and team coordination are necessary to prevent damage and guarantee accurate results.

Post-operational safety procedures must be followed to ensure a safe and successful testing experience.

Prior to initiating dynamometer operation, it is crucial to perform a series of pre-operational safety checks to guarantee a safe and controlled testing environment.

The test object must be properly secured and aligned to prevent damage or injury from uncontrolled movement or flying debris. A visual inspection of the dynamometer and associated equipment is necessary to identify any signs of wear, damage, or malfunction that could compromise safety or test results.

All safety guards and protective shielding must be in place and functioning correctly to prevent operator exposure to moving parts or hazardous materials. The dynamometer's power source and electrical connections must be checked to confirm they are secure, properly rated, and meet relevant safety standards to prevent electrical shock or fire hazards.

The test protocol and operating procedures must be reviewed to confirm they are up-to-date, relevant, and compliant with industry standards and regulatory requirements to minimise risks and guarantee accurate test results. Performing these pre-operational safety checks ensures a safe and reliable testing environment.

When operating a dynamometer, personal protective equipment (PPE) is indispensable to prevent injuries and guarantee a safe working environment.

Eye protection gear, such as safety glasses or goggles, is paramount to shield against debris and other hazards that may affect the operator's vision.

Furthermore, gloves and hand safety measures are imperative to prevent hand injuries and maintain control when handling dynamometer components or test objects.

Among key components of personal protective equipment required for dynamometer operation is eye protection gear, a pivotal safeguard against eye injuries from flying debris or other hazards.

The Occupational Safety and Health Administration recommends dynamometer operators wear ANSI Z87.1-compliant eye protection gear to guarantee optimal protection. Safety glasses or goggles with polycarbonate lenses are an ideal choice, providing superior impact resistance and optical clarity.

When selecting eye protection gear, it is vital to consider the type of dynamometer being used, the operating environment, and potential hazards present.

This ensures the gear provides adequate protection for the operator. Regular inspection and maintenance of eye protection gear are also paramount to guarantee it remains in good condition and continues to provide optimal protection.

Dynamometer operators can markedly reduce the risk of eye injuries and create a safer working environment if they adhere to these guidelines.

Dynamometer operators can guarantee their hands remain protected from the harsh forces and sharp edges involved in dynamometer operation by wearing appropriate hand protection gear, specifically designed to alleviate the risks associated with dynamometer use.

Gloves are a vital component of personal protective equipment (PPE) for dynamometer operators, as they provide a barrier against cuts, abrasions, and crushing injuries.

When selecting gloves for dynamometer operation, it is pivotal to choose ones that offer a secure grip, even in oily or wet conditions.

A good grip is vital to maintain control of the dynamometer, ensuring a firm handhold and preventing accidents. Gloves with reinforced palms and fingers provide additional protection against punctures and tears.

Gloves with grip strength amplification features, such as textured palms or grip strips, can further reduce the risk of slippage.

Wearing the right gloves enables dynamometer operators to safeguard their hands and maintain a secure grip, ultimately ensuring a safe and successful testing experience.

Proper maintenance and calibration of dynamometers are vital to guarantee accurate test results and extend the lifespan of the equipment.

Regular calibration schedules, dynamometer cleaning procedures, and pre-use inspection checklists are fundamental components of a thorough maintenance program.

Accuracy is the cornerstone of reliable dynamometer testing, and regular calibration schedules are crucial to maintaining this accuracy.

Calibration verifies that test results are trustworthy, and any deviations from expected outcomes can be promptly identified and addressed. A well-planned calibration schedule prevents inaccurate data, which can lead to faulty test procedures and compromised ease of use.

Regular calibration helps extend the lifespan of the dynamometer, reducing the need for repairs and minimising downtime.

Scheduling calibration at regular intervals confirms that the dynamometer remains in optimal working condition, providing consistent and reliable results. Calibration schedules can be tailored to specific test procedures, certifying that the dynamometer is calibrated to meet the unique requirements of each test.

Maintaining the highest level of accuracy certifies that test results are reliable and trustworthy.

Regular dynamometer use necessitates thorough cleaning procedures to guarantee reliable test results and prevent the spread of infection.

A clean dynamometer is vital for accurate grip strength measurements and to safeguard the safety of both the operator and the test subject.

Cleaning the dynamometer involves wiping it down with a soft cloth and mild soap solution, followed by a rinse with distilled water, and drying with a clean towel to prevent water spots.

A soft-bristled brush can be used to gently remove any debris or residue from the dynamometer's grip surfaces, taking care not to scratch or damage the device.

It is crucial to refer to the manufacturer's instructions for specific cleaning and maintenance procedures, as different dynamometers may have unique requirements.

A dynamometer in good working condition is crucial for obtaining reliable grip strength measurements and safeguarding the safety of both the operator and the test subject.

To achieve this, a pre-use inspection checklist is necessary for dynamometer maintenance and calibration. This checklist should include a visual examination of the device for signs of wear, damage, or corrosion, along with verification of proper assembly and connection of all components.

The dynamometer's load cell should be calibrated annually, or according to the manufacturer's recommended schedule, to guarantee accurate measurement of grip strength and prevent false readings.

Calibration should be performed using a known weight or force, and the results should be recorded and compared to the manufacturer's specifications to guarantee accuracy within ±1% of the full scale.

The dynamometer's hydraulic or pneumatic systems should be checked for leaks, and the fluid levels should be topped off as necessary.

The pre-use inspection checklist should include a review of the dynamometer's electrical components, including cables and connectors, to guarantee they are securely attached and free from damage.

This comprehensive inspection will ensure the dynamometer is functioning correctly and providing accurate results.

During dynamometer testing, adhering to safe testing procedures and protocols is crucial to guarantee the reliability of test results, prevent damage to equipment, and safeguard the well-being of operators and bystanders.

To ensure a safe and successful testing process, operators should follow established protocols for grip strength testing, including hand grip strength assessments.

This entails certifying the dynamometer is properly calibrated and configured for the specific grip test being conducted.

Additionally, operators must instruct test subjects on proper grip technique and test procedures to minimize the risk of injury or equipment damage.

A safe testing environment, free from distractions and hazards, must also be maintained, and all personnel involved in the testing process must be aware of their roles and responsibilities.

Beyond the importance of safe testing procedures and protocols lies the critical need for emergency response planning and training.

A dynamometer, a powerful tool, poses risks to users, particularly when testing grip strength or other physical attributes. In the event of an accident or equipment failure, a well-planned emergency response means the difference between a minor incident and a serious injury.

Facilities should develop an exhaustive emergency response plan, outlining procedures for responding to diverse scenarios, such as equipment malfunction, user injury, or facility evacuation.

This plan should be communicated to all personnel and regularly reviewed and updated to validate its effectiveness.

Training sessions are essential to familiarise personnel with the emergency response plan, providing them with the necessary skills to respond efficiently in an emergency.

Prioritising emergency response planning and training enables facilities to minimise the risk of accidents and guarantee a safe testing environment for users.

A well-planned emergency response is essential, but its successful execution relies heavily on clear communication and team coordination.

In a dynamometer testing environment, effective communication is pivotal to guarantee that all team members are aware of their roles and responsibilities, particularly during high-stress situations. Clear communication helps prevent misunderstandings, reduces errors, and promotes a sense of trust and accountability among team members.

To achieve seamless team coordination, consider the following best practices:

Designate a lead tester to oversee the testing process and provide guidance to other team members as needed.

Establish a standardized communication protocol for reporting test results, including grip strength measurements, to certify consistency and accuracy.

Conduct regular team meetings to review testing procedures, discuss challenges, and share best practices to guarantee that all team members are on the same page.

Accurate and reliable test results rely on regular dynamometer inspections, crucial to guaranteeing the integrity of the testing process.

Inspections should be performed at least once a month or after 100 tests, whichever comes first. During these inspections, it is necessary to check for signs of wear and tear, corrosion, or damage on the dynamometer's mechanical components, electrical connections, and cables.

Calibration of the dynamometer should also be performed every 6-12 months or as specified by the manufacturer to guarantee accurate readings and prevent drift.

A quality control checklist should be maintained to track inspection and calibration schedules, in addition to any maintenance or repairs performed on the dynamometer.

This checklist ensures that all necessary steps are taken to certify the dynamometer's reliability and accuracy. The dynamometer's operating manual should be consulted for specific inspection and quality control procedures, as different models may have unique requirements.

Users can guarantee their dynamometer is functioning correctly, providing trustworthy test results and maintaining a safe testing environment, by following these guidelines.

Proper post-operational safety procedures are vital to guaranteeing the dynamometer's longevity, accuracy, and reliability.

After completing a test, operators must follow established safety protocols to prevent damage, guarantee accurate results, and maintain a safe working environment.

Operators should clean and store the dynamometer according to the manufacturer's guidelines to prevent damage and guarantee accurate results in future tests.

A thorough inspection of the dynamometer and its components should be conducted after each use to identify any signs of wear or damage that may affect test results.

The dynamometer should be recalibrated regularly to guarantee accuracy and reliability, and a record of calibration dates and results should be maintained.

Safety Protocols and Best Practices for Dynamometer Use

Pre-Operational Safety Checks

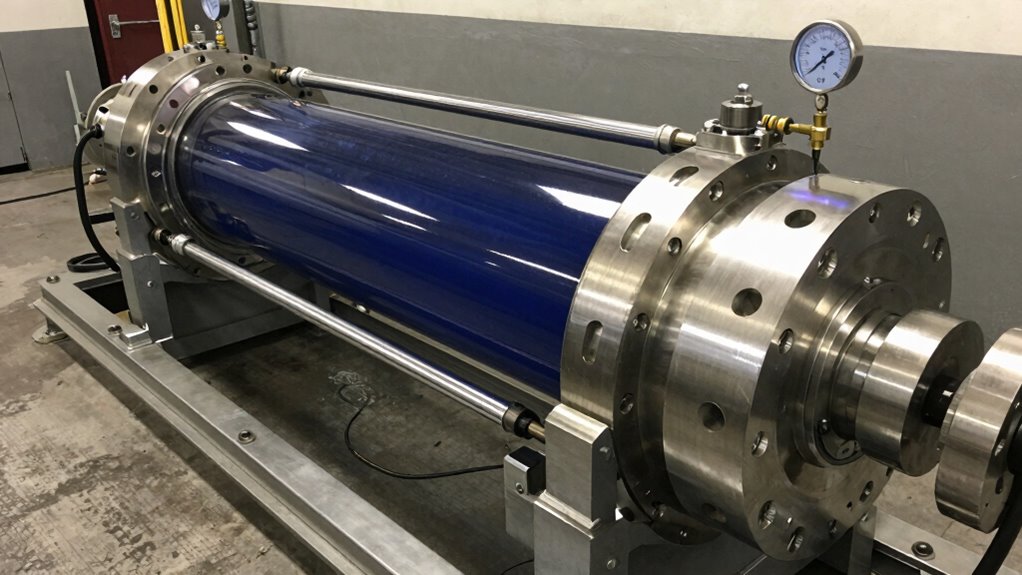

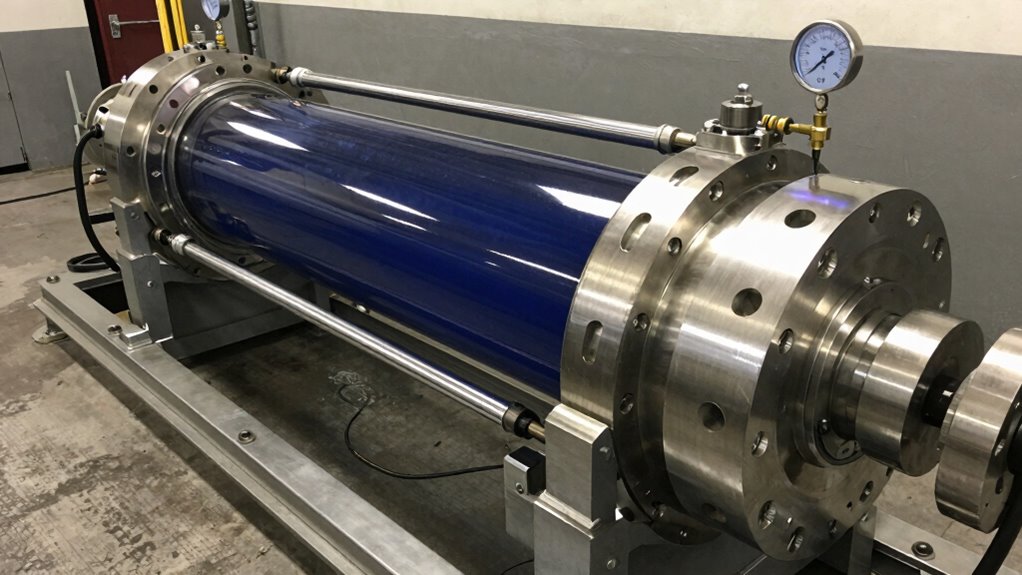

Before operating a dynamometer, a series of safety checks must be performed to ensure a safe testing environment. This includes inspecting the equipment for any signs of damage or wear, verifying proper installation and securement, and checking that all necessary safety features are functioning correctly. If you have any questions about our Custom Dyno Solutions, please contact Hyper Power.

Personal Protective Equipment Requirements

Operators and testing personnel must wear appropriate personal protective equipment (PPE) when working with dynamometers. This typically includes safety glasses, gloves, and closed-toe shoes. Additional PPE may be required depending on the specific testing application and environment. Our Installation and Setup team can provide guidance on the necessary PPE for your specific needs.

Dynamometer Maintenance and Calibration

Regular maintenance and calibration of dynamometers are vital to obtaining accurate and reliable test results. This includes routine cleaning and lubrication, as well as scheduled calibration and certification to guarantee compliance with industry standards. Hyper Power offers Technical Support and Maintenance services to ensure your dynamometer is always in top condition.

Safe Testing Procedures and Protocols

Established testing procedures and protocols must be followed to guarantee safe and controlled testing operations. This includes defining test parameters, setting safety limits, and establishing emergency shutdown procedures. Our Training and Certification program can provide your team with the necessary skills and knowledge to ensure safe and effective testing.

Emergency Response Planning and Training

A thorough emergency response plan must be developed and regularly practiced to guarantee that operators and testing personnel are prepared to respond quickly and effectively in the event of an emergency. Hyper Power offers Diagnostics and Performance Analysis services to help identify potential issues before they become emergencies.

Clear Communication and Team Coordination

Clear communication and teamwork are fundamental for safe and efficient dynamometer operation. Operators, testing personnel, and support staff must be aware of their roles and responsibilities and communicate effectively to guarantee a coordinated testing effort. Our Rental Services team can provide additional support and resources to ensure a smooth testing operation.

Dynamometer Inspection and Quality Control

Regular inspection and quality control measures must be implemented to guarantee that dynamometers are functioning correctly and safely. This includes visual inspections, performance testing, and certification to industry standards. Hyper Power offers Accessories and Parts to ensure your dynamometer is always functioning at its best.

Post-Operational Safety Procedures

Following testing operations, a series of post-operational safety procedures must be performed to guarantee the dynamometer is safely shut down and secured. This includes powering down the equipment, securing test specimens, and performing a final safety inspection. Our Software Updates and Upgrades team can ensure your dynamometer software is always up-to-date and secure.

Conclusion

Adherence to established safety protocols and best practices is vital for safe and effective dynamometer operation. By following these guidelines, operators and testing personnel can minimize the risk of accidents and guarantee reliable test results. If you have any questions or concerns about dynamometer safety, please contact Hyper Power for more information on our Dynamometer Testing Services.

Hydraulic dynos prevent catastrophic field failures—but most heavy industry operators still skip this critical step. Learn why.

Most diesel dyno operators ignore this—and it costs them thousands in failed runs and wasted data.

Stop wasting money on road testing. One dyno investment eliminates comebacks, builds loyalty, and outpaces competitors. Here’s why your workshop needs it.

Diesel turbo lag isn’t inevitable—modern dyno diagnostics reveal the hidden culprits stealing your power. Find out what your engine is hiding.

Fleet operators are throwing money away. Dynos reveal what road tests miss—and how much you’re losing.

Water testing won’t reveal what dyno testing exposes. Learn why engine builders skip this step at their peril.

Tractor performance tests reveal what manufacturers won’t tell you. See how dynamometer data exposes hidden inefficiencies in your equipment.

Diesel engine testing mistakes cost thousands monthly. Learn what separates thriving operations from regulatory nightmares.

No posts found!