Why Top Tuning Shops Choose Hyper Power Dynamometers

Tune into the unparalleled precision and power optimization that top tuning shops crave with Hyper Power Dynamometers – setting a new standard in performance enhancement.

When purchasing a dynamometer, pay attention to its power capacity to ensure it can handle the required output levels accurately.

Verify that it is compatible with various vehicle types and transmissions to guarantee seamless operation.

Evaluate the data acquisition system to ensure it is compatible, precise, and equipped with essential software features. Calibration plays a crucial role in achieving precision, and regular updates enhance efficiency.

Opt for a robust build quality using materials like steel for long-lasting durability. Stability is key, so choose a dynamometer with precise engineering and commit to regular maintenance for accurate results.

Look for reliable after-sales support for upkeep and training to maintain optimal testing accuracy and performance.

Power Capability

When considering the purchase of a dynamometer, assessing its power capacity is crucial to ensure it can accommodate the torque and power output requirements of the engines or vehicles under test. Dynamometers vary in their power capabilities, so it is essential to choose one that can handle the maximum power output you anticipate testing.

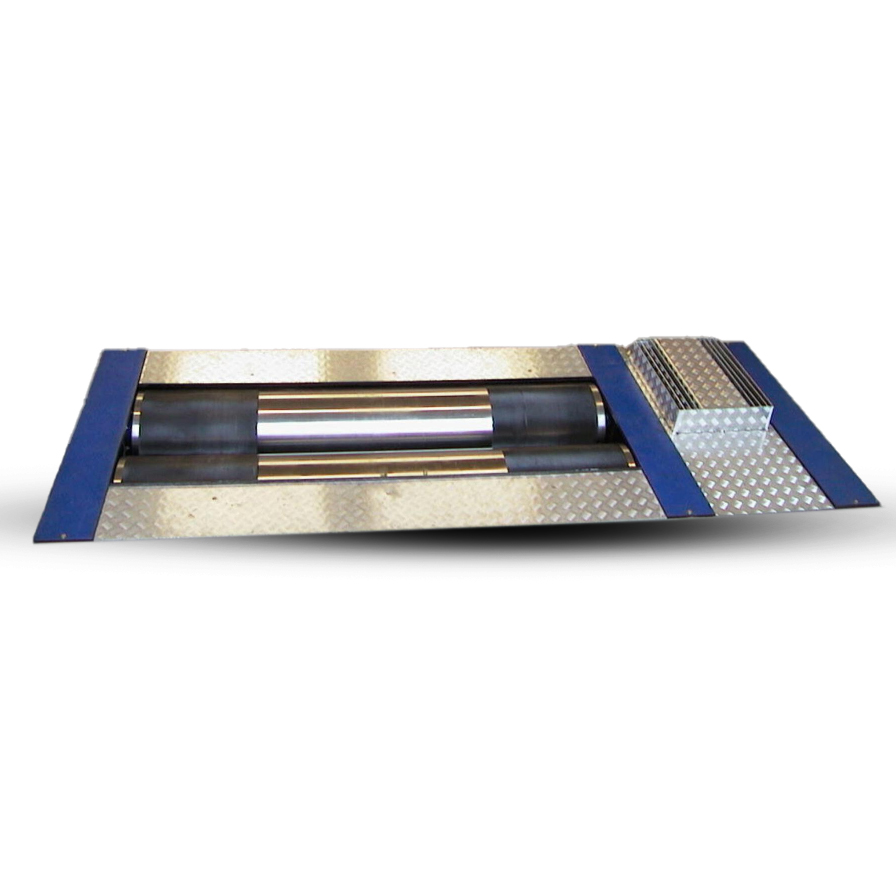

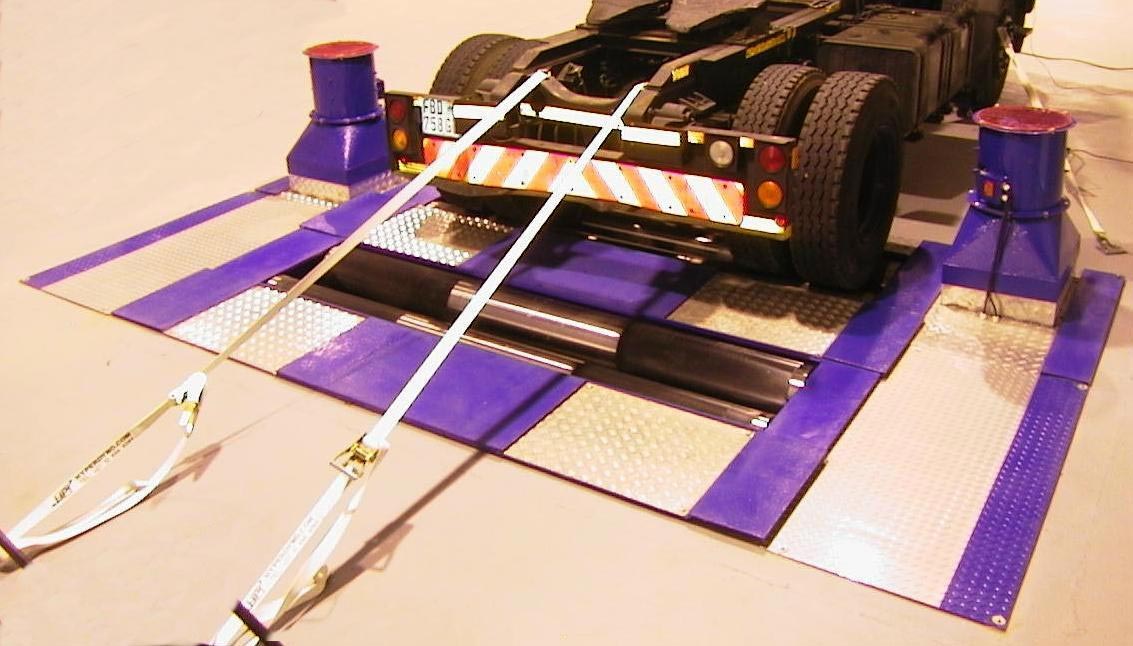

Checking the power range of the dynamometer ensures it is suitable for the torque and power levels of the engines or vehicles you plan to assess. For instance, dynamometers like those in the HP range are tailored for applications needing high torque and power, delivering precise and dependable results. Advanced features such as bi-roller solutions, as seen in models like the BPM-2RHP, cater to specific testing requirements.

The precision, repeatability, and reliability of a dynamometer’s power capacity are crucial for achieving consistent and accurate test results. Therefore, when investing in a dynamometer, always consider the power capability to meet your testing needs effectively.

Vehicle Suitability Assessment

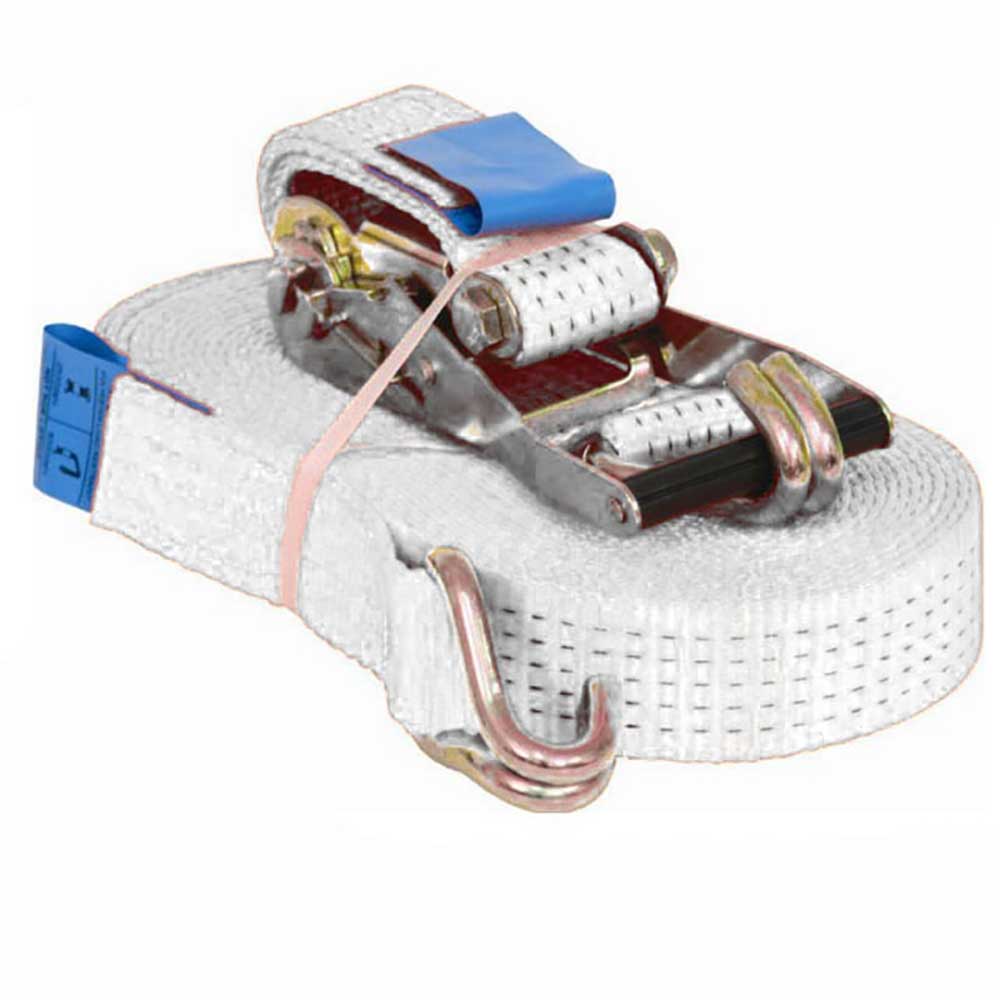

When selecting a dynamometer for testing purposes, it is crucial to assess its compatibility with a range of vehicles. This includes considering factors such as engine size, power output, and drivetrain configuration. Chassis dynamometers are versatile, catering to vehicles like motorcycles and trucks. It is essential to choose a dynamometer that can test both two-wheel-drive (2WD) and four-wheel-drive (4WD) vehicles for comprehensive testing options. Additionally, the dynamometer should be capable of testing various transmission types, such as manual, automatic, or CVT, to accurately cover a diverse range of vehicles.

Customisable Settings for Precise Testing

Opting for a dynamometer that offers customisable settings for different vehicle parameters is vital for accurate testing. This feature allows for precise testing across different vehicle models, meeting specific testing requirements effectively. Having the ability to adjust settings according to the vehicle being tested enhances the dynamometer’s usability and ensures reliable testing results. For example, Dynamometer X offers customisable settings for engine size and power output, allowing for tailored testing procedures for a wide range of vehicles.

Flexibility and Adaptability for Varied Vehicles

When considering vehicle compatibility, choosing a chassis dynamometer that is flexible and adaptable to different vehicle types and configurations is essential. This adaptability ensures that the dynamometer can accommodate various vehicles, from small cars to heavy-duty trucks, without limitations. Dynamometer Y, known for its versatility, can handle a wide array of vehicles, making it a practical choice for testing facilities with diverse testing needs. This flexibility allows for seamless testing of different vehicle models, ensuring accurate and reliable results across the board.

When considering a dynamometer purchase, the data acquisition system is a critical component to assess. System compatibility guarantees smooth integration with existing equipment, while data accuracy ensures reliable results.

These two points are fundamental in selecting a dynamometer with a strong data acquisition system.

System Compatibility for Dynamometers and Data Acquisition Systems

Ensuring seamless integration and accurate data collection involves verifying the full compatibility of the chosen dynamometer with the data acquisition system in use. It is crucial to confirm that the dynamometer aligns with the data acquisition system to prevent any potential issues.

Check if the dynamometer supports the necessary communication protocols required by your setup to avoid compatibility issues in the future. Additionally, it is vital to verify that the dynamometer’s software can efficiently interface with your existing data acquisition system for optimal testing and analysis processes.

Opt for dynamometers that offer customizable data output options to facilitate integration with your specific data acquisition system. Consider the scalability of the dynamometer’s data acquisition capabilities to ensure it can accommodate any future upgrades or changes in testing requirements.

For example, when selecting a dynamometer for automotive testing, ensure that it is compatible with commonly used data acquisition systems such as the AVL PUMA or the Dewesoft systems. This compatibility will enable seamless data transfer and analysis during engine performance testing or emissions analysis.

Additionally, dynamometers like the Dynapack range offer versatile data output options, making them suitable for integration with various data acquisition systems commonly found in automotive testing facilities. By choosing a dynamometer with robust compatibility features, you can streamline your testing processes and enhance overall efficiency.

Data Precision in Dynamometer Testing

Data precision plays a crucial role in dynamometer testing, ensuring accurate measurements of torque, power, and engine performance. To ensure dependable data collection, invest in a high-quality data acquisition system that offers real-time monitoring capabilities. These systems enable immediate tracking and analysis of engine parameters, aiding in the evaluation of performance. Advanced data acquisition systems offer customisable features tailored to specific testing requirements, enhancing accuracy and efficiency. The accuracy of the data acquisition system significantly impacts the tuning and optimisation process for engines, making it a vital consideration when purchasing a dynamometer. Prioritising data precision streamlines testing procedures and leads to more precise results, ultimately enhancing overall performance evaluation.

Benefits of Accurate Data Acquisition Systems

Investing in a reliable data acquisition system provides numerous benefits in dynamometer testing. For example, the AVL PUMA Open data acquisition system offers advanced data processing capabilities, ensuring precise measurement and analysis of engine performance parameters. This system allows for real-time monitoring and control of test processes, facilitating quick adjustments and accurate data collection. By utilising such a system, engineers can efficiently evaluate engine performance, identify areas for improvement, and enhance overall testing accuracy.

Enhancing Engine Tuning and Optimisation

Accurate data acquisition systems are essential for fine-tuning and optimising engine performance. With the Dewesoft X data acquisition system, engineers can access a wide range of customisable features to tailor data collection to specific testing needs. This level of precision enables detailed analysis of torque curves, power output, and other critical engine parameters, leading to more informed tuning decisions. By utilising advanced data acquisition systems, engineers can achieve optimal performance levels and enhance the efficiency of the tuning process.

Improving Overall Performance Evaluation

The accuracy of data collected through a high-quality data acquisition system is crucial for comprehensive performance evaluation. For instance, the MTS Echo Smart data acquisition system offers superior data accuracy and reliability, ensuring precise measurement of torque and power during dynamometer testing. This level of precision allows for in-depth analysis of engine performance, enabling engineers to make informed decisions for enhancing overall efficiency and output. By prioritising data accuracy in performance evaluation, organisations can achieve better results and drive continuous improvement in engine performance.

When selecting a dynamometer, software integration is crucial to maximizing its capabilities. Confirm the software is compatible with popular engine management systems for improved tuning options.

Seek out features like real-time monitoring and automatic data logging to streamline your testing process.

Compatibility with Devices

Ensuring seamless integration between dynamometer software and existing devices is crucial for efficient data collection and analysis in performance tuning. It is essential to verify compatibility with popular engine management systems such as EFI Live, HP Tuners, and Cobb Tuning when evaluating current dynamometers. These systems are integral to the tuning process, and having software that can work in harmony with them ensures a smooth tuning experience. Choosing dynamometers that provide customisable software options tailored to specific tuning needs can greatly impact achieving optimal performance results. Real-time adjustments and feedback support immediate optimisation, while comprehensive data logging capabilities offer detailed insights for precise tuning modifications. Prioritising compatibility with devices can streamline the tuning process and enhance performance outcomes.

Product Recommendations: Consider dynamometers like Dynojet Power Vision, which is known for its compatibility with a wide range of engine management systems, making it a versatile choice for tuning enthusiasts.

Optimising Performance Tuning with Compatible Software

Selecting dynamometer software that is compatible with popular engine management systems is essential for a smooth and effective tuning process. Engine management systems like EFI Live, HP Tuners, and Cobb Tuning are widely used in the tuning community, and having software that can seamlessly integrate with them is key to achieving optimal results. Customisable software options tailored to specific tuning requirements can make a significant difference in the tuning process, allowing for precise adjustments and fine-tuning. Compatibility with devices ensures that data collection and analysis are seamless, leading to improved performance outcomes.

Specific Example: A dyno software like AEM Performance Electronics offers compatibility with a variety of engine management systems, making it a reliable choice for tuners looking for seamless integration and efficient tuning processes.

Prioritising Device Compatibility for Performance Tuning Success

Emphasising compatibility with devices is paramount for successful performance tuning outcomes. Choosing dynamometer software that aligns with popular engine management systems such as EFI Live, HP Tuners, and Cobb Tuning can significantly impact the tuning process’s efficiency and effectiveness. Software that can be customised to suit specific tuning needs enables tuners to make precise adjustments and optimisations for enhanced performance. Seamless integration with devices allows for real-time adjustments, immediate feedback, and thorough data logging capabilities, all of which contribute to achieving the desired tuning results.

Product Recommendation: Look into Mustang Dynamometer’s software offerings, known for their compatibility with a wide range of engine management systems, ensuring a smooth and productive tuning experience.

Data Analysis Capabilities

To enhance the efficiency of performance tuning processes, prioritising dynamometers with advanced data analysis capabilities is crucial for obtaining valuable insights into engine performance metrics. The integration of software plays a key role in enabling real-time monitoring of essential parameters like torque, horsepower, and engine speed during testing. The data analysis software not only aids in identifying engine issues but also in fine-tuning performance to achieve optimal outcomes. By connecting with external sensors, these dynamometers facilitate comprehensive data collection, allowing for detailed analysis. Moreover, compatibility with industry-standard software enhances data sharing and comparison, ensuring precise results in the field of engine testing. Selecting a dynamometer with robust data analysis capabilities can significantly impact the success of your performance tuning efforts.

Examples: The DynoWare RT system and the PowerNet software are excellent options that provide advanced data analysis features for engine testing applications. These tools offer real-time monitoring and detailed performance analysis, making them valuable assets for performance tuning specialists.

Calibration and Software Updates in Dynamometer Testing

Calibration and software updates are vital for ensuring the accuracy and functionality of dynamometers in engine testing setups. Calibration is essential to guarantee precise and reliable measurements, which are crucial for obtaining dependable results.

Regular software updates not only enhance the dynamometer’s performance but also introduce new features that can improve testing efficiency. Integrated software plays a crucial role in enabling seamless data collection and analysis, thereby streamlining the testing process.

By maintaining proper calibration and software integration, the dynamometer’s reliability and consistency are preserved. Additionally, advanced software capabilities allow for customisation of test parameters and interpretation of results, leading to better tuning outcomes.

Staying up-to-date with calibration and software updates is essential for maximising the potential of dynamometers in engine testing.

Calibration and Precision

Maintaining accuracy in dynamometer measurements through consistent calibration is crucial for evaluating engine performance during testing. Calibration ensures that the dynamometer measures within specified tolerances, providing precise data essential for engine tuning and development. Regular calibration checks are essential to uphold the dynamometer’s accuracy and reliability, aligning with industry standards for consistent results.

Inaccurate readings due to lack of proper calibration can result in incorrect determinations and decisions in engine performance optimization. Engineers and enthusiasts rely on precise dynamometer readings to make informed choices, highlighting the significance of calibration in dynamometer usage. Prioritising calibration and accuracy allows users to have confidence in the data obtained from the dynamometer, leading to more successful engine testing and development processes.

Build Quality

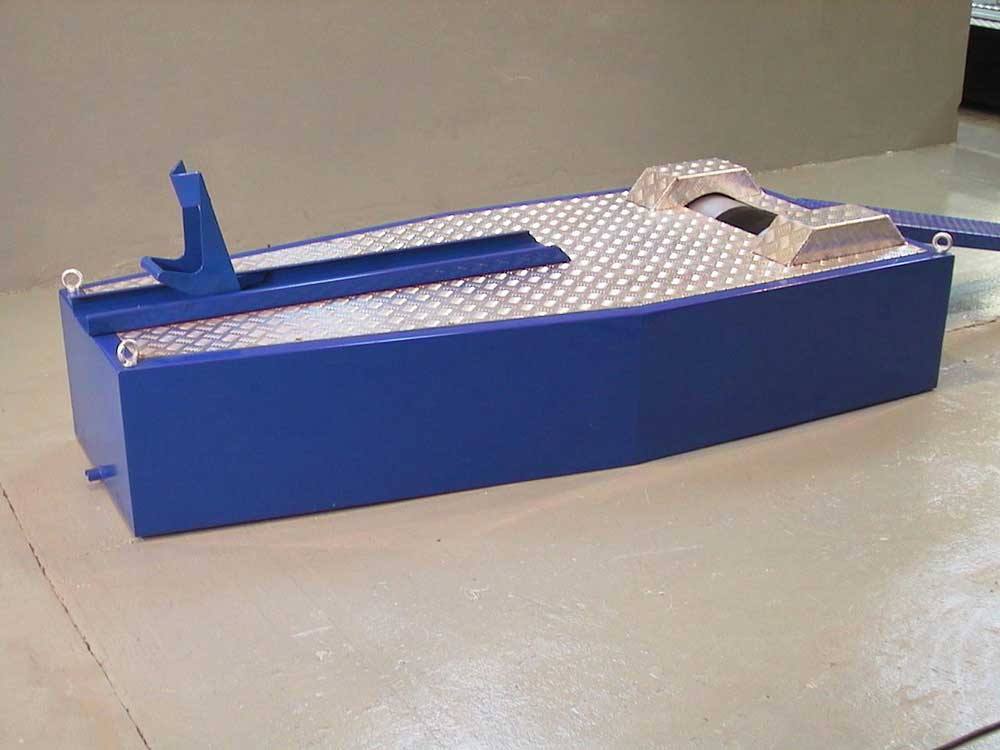

When assessing a dynamometer, the construction quality plays a crucial role in its longevity and testing precision. A top-tier chassis dyno is crafted using sturdy materials such as steel to ensure durability. Precise machining of the dynamometer’s components boosts its performance and dependability, resulting in more precise test outcomes. Elements like reinforced frames and load cells enhance the dynamometer’s stability during testing procedures. Stringent quality control measures applied during production ensure reliable and consistent results, making the dynamometer a trusted tool for diverse testing requirements.

| Build Quality Features | Description |

|---|---|

| High-Quality Materials | Steel construction for durability and strength |

| Precision Machining | Ensures precise component performance |

| Robust Design Features | Reinforced frames and load cells for enhanced stability |

| Quality Control Measures | Implemented during production to ensure accurate and consistent results |

After-Sales Support

Effective after-sales support is crucial for the smooth operation and longevity of a dynamometer system. It includes technical assistance, troubleshooting, maintenance services, and more. Manufacturers that provide comprehensive after-sales support ensure that users can quickly resolve any issues, keeping the dynamometer functioning optimally.

A key element of after-sales support is the availability of training programmes. These programmes are designed to help users understand the dynamometer’s functionality, perform proper maintenance, and effectively troubleshoot common issues. Additionally, regular software updates and calibration services offered by the manufacturer are essential components of after-sales support that contribute to the dynamometer’s peak performance.

When selecting a dynamometer supplier, it is important to assess the warranty coverage, availability of spare parts, and on-site support. Reliable after-sales support enhances user satisfaction and minimises downtime, maximising the overall lifespan of the dynamometer system.

In summary, when purchasing a dynamometer, it is essential to consider factors such as power capacity, vehicle compatibility, data acquisition system, software integration, calibration and accuracy, build quality, and after-sales support. By thoroughly evaluating these aspects, you can ensure that you are making an informed decision and investing in a high-quality dynamometer that meets your specific needs and requirements.

Guide Towards Further Learning:

Spark curiosity for more knowledge by inviting the reader to contact Hyper Dyno (talk about the company in the first person). Lead them to contact us if they have any questions about Dynamometer Products, Custom Solutions, Installation Setup, Training and Certification, Technical Support and Maintenance, Software Updates, Rental Services, Dynamometer Testing Services, and Accessories and Parts, making this a call to action. Bold all of these anchor texts and services to highlight their importance. Also bold the words ‘Hyper Dyno’.

Tune into the unparalleled precision and power optimization that top tuning shops crave with Hyper Power Dynamometers – setting a new standard in performance enhancement.

Uncover how precise testing impacts vehicle safety and performance, shaping the future of road safety in surprising ways.

Harness the power of dynamometers across various industries to unlock unparalleled performance – discover their transformative impact!

Peek into how dynamometers have transformed vehicle tuning, promising precision and power enhancements beyond imagination.

Yield to the allure of personalized wealth management services at Hyper Power and discover the transformative journey that awaits.

Harness the power of dynamometers to revolutionize automotive engineering and push the boundaries of innovation in the industry.

Uncover how a dynamometer unlocked performance gains beyond expectations, revolutionizing vehicle capabilities.

Accelerate your business growth with hyper power dynamometers, revolutionizing efficiency and performance optimization in various industries.

Hyper Power, the leading name in dynamometer solutions, offers unparalleled precision and reliability for all your performance testing needs.